Test jack for reactive controllable chip

A technology of chip testing and sockets, which is applied to the parts of electrical measuring instruments, measuring electronics, measuring devices, etc., can solve the problems of unsatisfactory reactance, machinability, low price, and increased frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

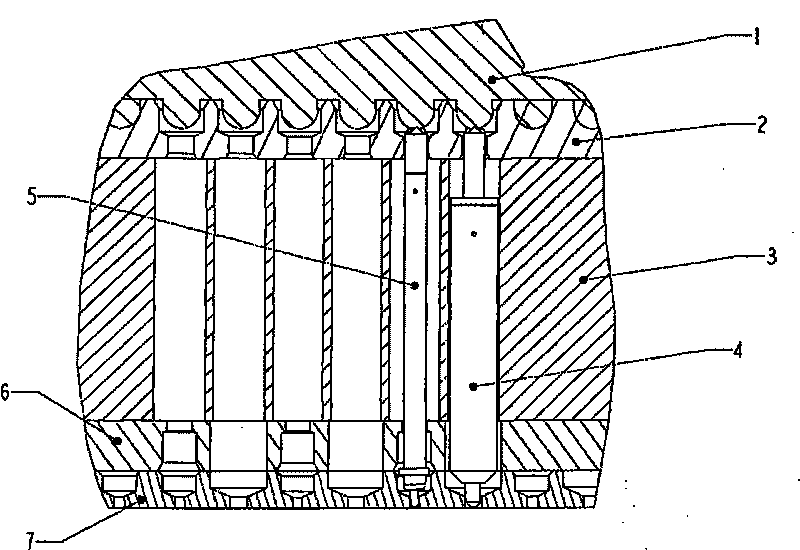

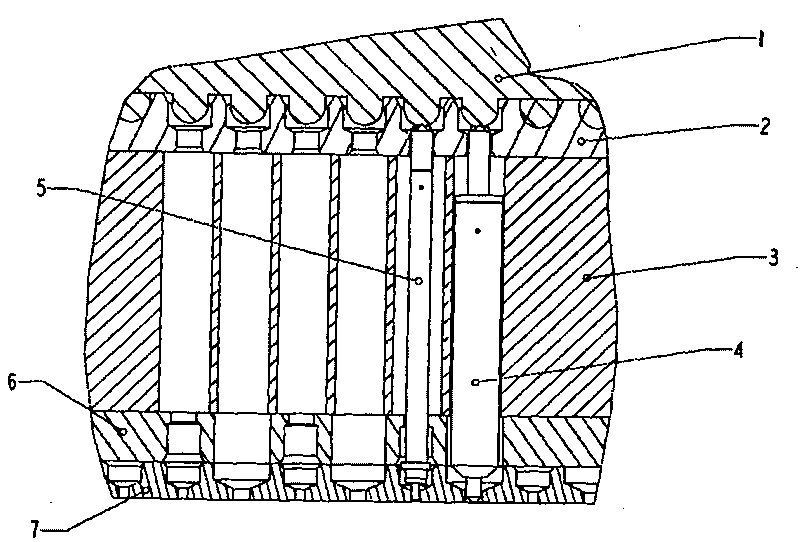

[0007] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0008] Use screws to fix the chip holding plate 2 and the grounding copper block 3 together, and then select the corresponding probe positioning plate 6 according to the contact distribution of the chip 1, and install the grounding spring probes respectively according to different cavity diameters. Pin 4 and signal / power spring probe 5, then install the probe holding plate 7, and fix it to the socket body with screws, and the entire socket can be assembled.

[0009] The chip holding plate 2 is made of insulating material, and the gaps between all the cavities and the probes 4, 5 are small, so that all the spring probes 4, 5 can be positioned and guided. At the same time, the chip holding plate 2 is also provided with large guide holes to ensure that the balls on the chip 1 are in contact with the spring probe heads 4,5.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com