Chopped fiber bundle, molding material, and fiber reinforced plastic, and process for producing them

A technology for chopped fibers and molding materials, which is applied in the field of fiber reinforced plastics and molding materials for molding fiber reinforced plastics, can solve the problems of increased production costs of SMC sheets, uneven distribution of reinforcing fibers, and reduced mechanical properties of molded bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

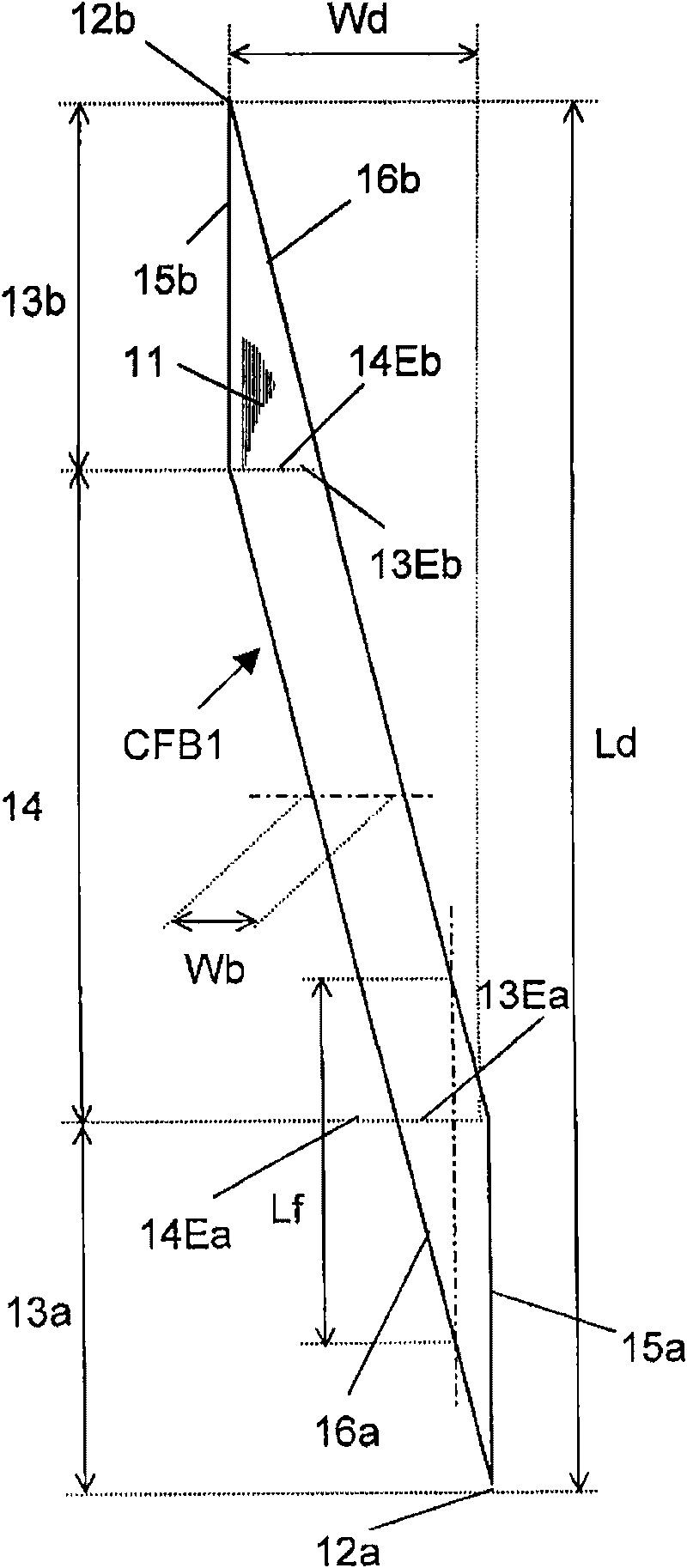

Embodiment 1

[0264] As the continuous reinforcing fiber bundle, a continuous reinforcing fiber bundle composed of a plurality of substantially untwisted and unsized carbon fibers is used. The diameter of the reinforcing fiber (monofilament) was 7 μm, the number of reinforcing fibers was 12,000, the tensile strength of the reinforcing fiber bundle was 5.0 GPa, and the tensile modulus of the reinforcing fiber bundle was 240 GPa. The continuous reinforcing fiber bundles are continuously immersed in the sizing agent mother liquor, the sizing agent is given to the continuous reinforcing fiber bundles so that the resin content is 2.0% by mass, and the reactive polyurethane resin emulsion is diluted with purified water in the sizing agent mother liquor (the first industry Pharmaceutical Co., Ltd. product, Superflex-R5000). The continuous reinforcing fiber bundle to which the sizing agent was applied was dried with a hot roll at 150° C. and a drying oven at 200° C. under a dry tension of 600 g / dte...

Embodiment 2

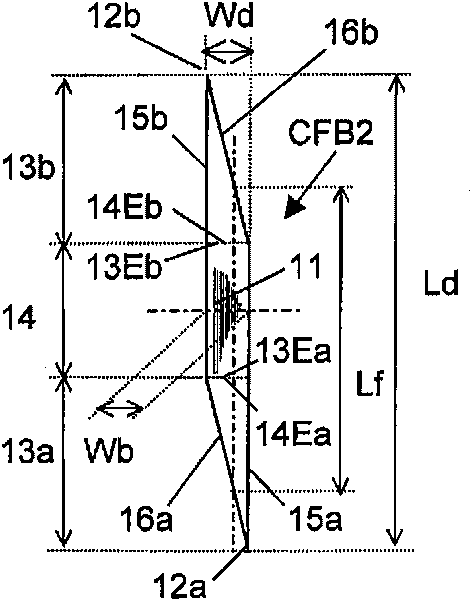

[0273] When cutting the same continuous reinforcing fiber bundles as in Example 1 to obtain chopped fiber bundles, knife edges were provided at intervals of 12.5 mm in the circumferential direction of the rotary cutter, and the continuous reinforcing fiber bundles were inserted at an angle of 30° to the knife edges. The resulting chopped fiber bundle is figure 2 Chopped fiber bundle CFB2 in the form shown. The sides 16a and 16b at the end of the chopped fiber bundle CFB2 have a linear form at an angle of 30° to the arrangement direction of the reinforcing fibers 11, the fiber length Lf of the reinforcing fibers 11 is 25mm, although 2% left and right differences. There are transition zones 13a and 13b where the number of reinforcing fibers increases in the arrangement direction of the reinforcing fibers 11 from the end to the center of the chopped fiber bundle CFB2, and the number of reinforcing fibers in the arrangement direction of the reinforcing fibers is 1,300 per mm. I...

Embodiment 3

[0278] As the continuous reinforcing fiber bundle, a continuous reinforcing fiber bundle (RS570M-521ZS, fiber basis weight 570 tex, manufactured by Nittobo Co., Ltd.) composed of a plurality of glass fibers adhered with a sizing agent was used. The continuous reinforcing fiber bundle was pulled out in an untwisted state from the copper tube by unwinding in the transverse direction, and cut in the same manner as in Example 1 to obtain a chopped fiber bundle. The resulting chopped fiber bundle is figure 2 Chopped fiber bundle CFB2 in the form shown. The sides 16a and 16b at the ends of the chopped fiber bundle CFB2 have a linear form at an angle of 12° to the direction in which the reinforcing fibers 11 are arranged, and the fiber length Lf of the reinforcing fibers 11 is 25 mm. % of the difference. From the end to the center of the chopped fiber bundle CFB2, there are transition zones 13a and 13b where the number of reinforcing fibers increases in the arrangement direction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com