Method for classifying calcium alginate plastic beads

A technology of calcium alginate and glue beads, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low classification efficiency, classification restriction, clogging, etc., and achieve high classification efficiency, easy operation and separation effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

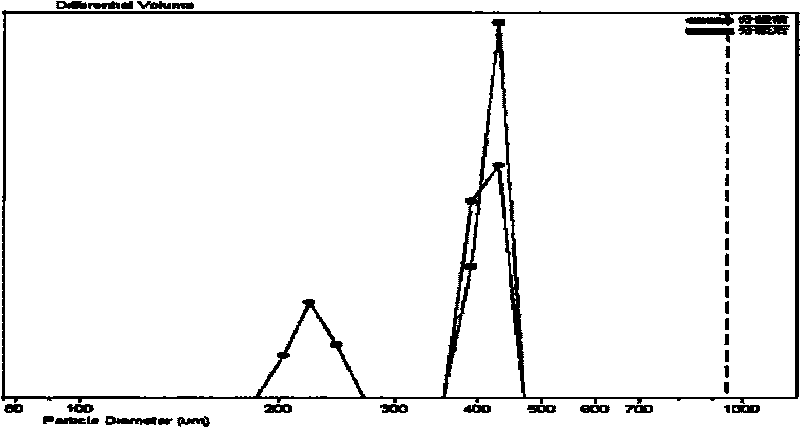

[0027] 1) Detect the particle size distribution of the rubber beads to be classified on the particle size analyzer (see figure 1 The blue distribution line in ), the particle size range of the beads includes two parts, the first part has a minimum particle size of 185 μm, a maximum particle size of 270 μm, and an average particle size of 225±15 μm; the second part has a minimum particle size of 356 μm, The maximum particle size is 471 μm, and the average particle size is 412±19 μm.

[0028] 2) Put the rubber beads to be classified in the fluidized bed, and the volume of the rubber beads accounts for 1 / 5 of the volume of the fluidized bed.

[0029] 3) Turn on the peristaltic pump, and slowly pump the calcium chloride solution with a concentration of 0.05mol / L from the fluid inlet 1 of the fluidized bed, and simultaneously open the fluid outlet 2 of the fluidized bed, and control the surface velocity of the fluid at 0.05cm / s, Until the fluid fills the entire cavity of the flui...

Embodiment 2

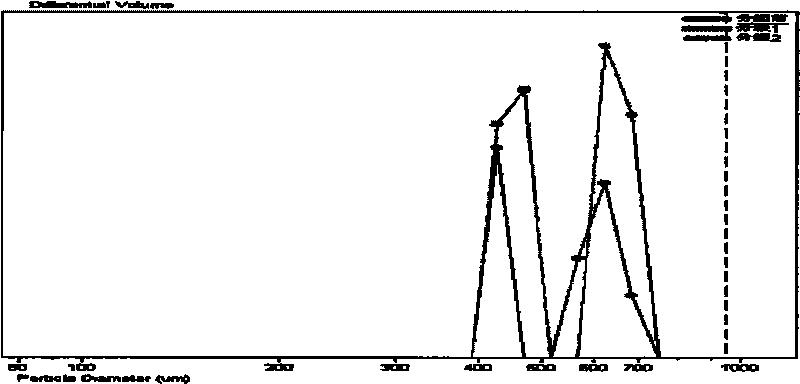

[0032] 1) Detect the particle size distribution of the rubber beads to be classified on the particle size analyzer (see figure 2 The blue distribution line in ), the particle size range of the beads includes two parts, the first part has a minimum particle size of 391 μm, a maximum particle size of 471 μm, and an average particle size of 429±20 μm; the second part has a minimum particle size of 517 μm, The maximum particle size is 751 μm, and the average particle size is 623±39 μm.

[0033] 2) Put the rubber beads to be classified in the fluidized bed, and the volume of the rubber beads accounts for 1 / 5 of the volume of the fluidized bed.

[0034] 3) Turn on the peristaltic pump, and slowly pump the calcium chloride solution with a concentration of 0.1mol / L from the fluid inlet 1 of the fluidized bed, and simultaneously open the fluid outlet 2 of the fluidized bed, and control the surface velocity of the fluid at 0.1cm / s. Until the fluid fills the entire cavity of the fluidi...

Embodiment 3

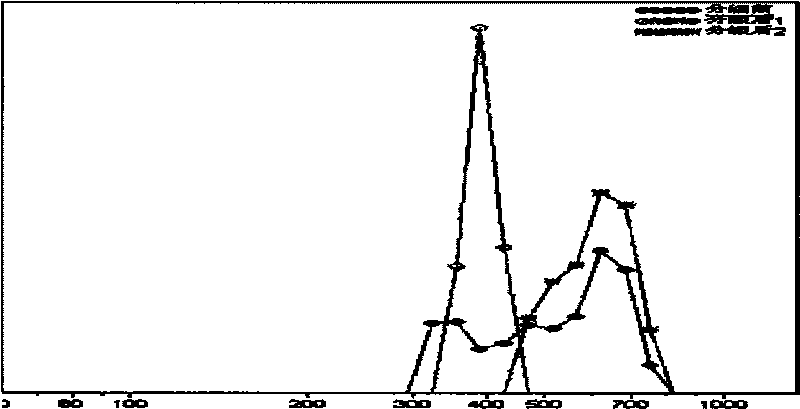

[0037] 1) Detect the particle size distribution of the rubber beads to be classified on the particle size analyzer (see image 3 The blue distribution line in the middle), the particle size distribution of the rubber beads is wide, the minimum particle size is 293 μm, and the maximum particle size is 815 μm.

[0038] 2) Put the rubber beads to be classified in the fluidized bed, and the volume of the rubber beads accounts for 1 / 10 of the volume of the fluidized bed.

[0039] 3) Turn on the peristaltic pump, and slowly pump the calcium chloride solution with a concentration of 0.3mol / L from the fluid inlet 1 of the fluidized bed, and simultaneously open the fluid outlet 2 of the fluidized bed, and control the surface velocity of the fluid at 0.06cm / s. Until the fluid fills the entire cavity of the fluidized bed.

[0040] 4) Slowly increase the speed of the peristaltic pump to increase the flow rate of the fluid until the bed expansion height of the rubber beads is consistent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap