Method for hoisting large-size workpiece in ordinary plant and hydraulic jacking equipment thereof

A large-scale workpiece and hydraulic lifting technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient stator rotation, backward construction methods, waste of social resources, etc., and achieve the effect of expanding applicability, high safety, and leading technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

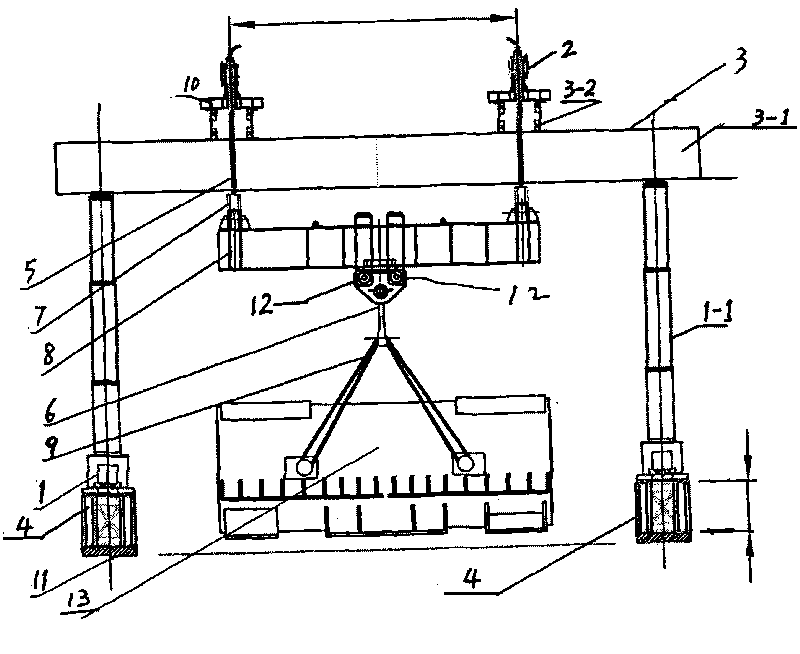

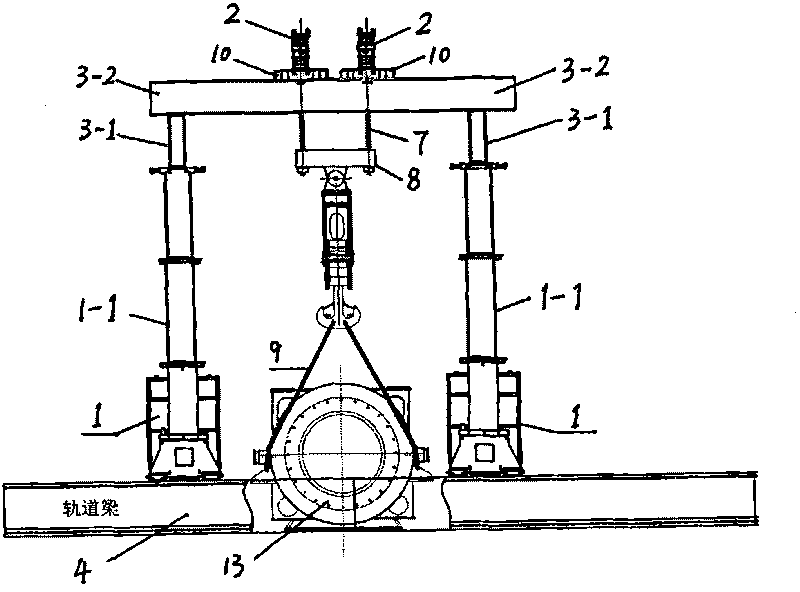

[0038] The present invention will be described in detail below by taking the hoisting of a large generator stator as an example.

[0039] Figure 1 to Figure 8 Constitute the specific embodiment 1 of the present invention.

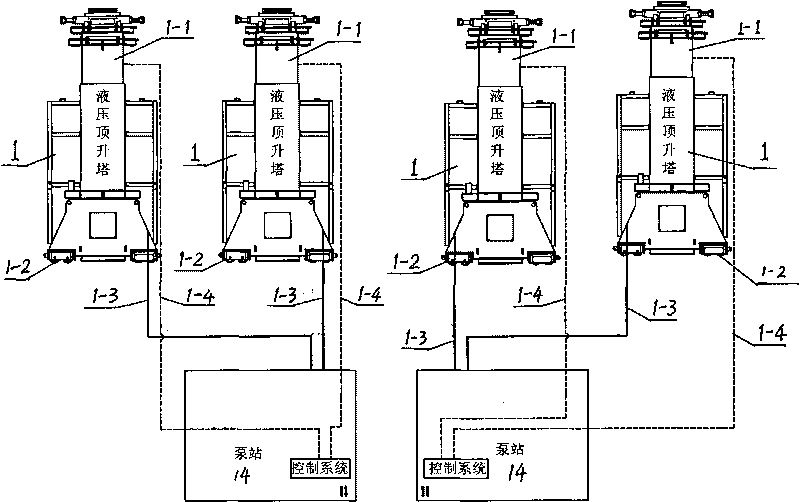

[0040] refer to Figure 8 , the present invention uses a hydraulic jacking system to lift the stator at the inspection port of the main workshop, transport it horizontally and lower it to the top of its installation foundation, and make it in place; it is characterized in that it includes the following steps:

[0041]1) The hydraulic lifting device of the hydraulic jacking system is erected above the hydraulic jacking tower through the hoisting beam, and connected with the hook through the steel cable. The hydraulic jacking towers are respectively arranged above the two rails, forming a whole Framework;

[0042] 2) After the stator is lifted to the height of the platform by the hydraulic lifting device, the walking hydraulic jacking tower sends the stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com