Automatic control device and method of rotary chute pair transmission tilt angle of blast furnace bell-less top

An automatic control device, a technology without a material clock, applied in the direction of control without feedback, arrangement of clocks and funnels, etc., can solve the problem that the precise position control of the transmission of the chute pair transmission cannot be realized, and can ensure the stability, maintain the output characteristics, The effect of preventing frequent switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

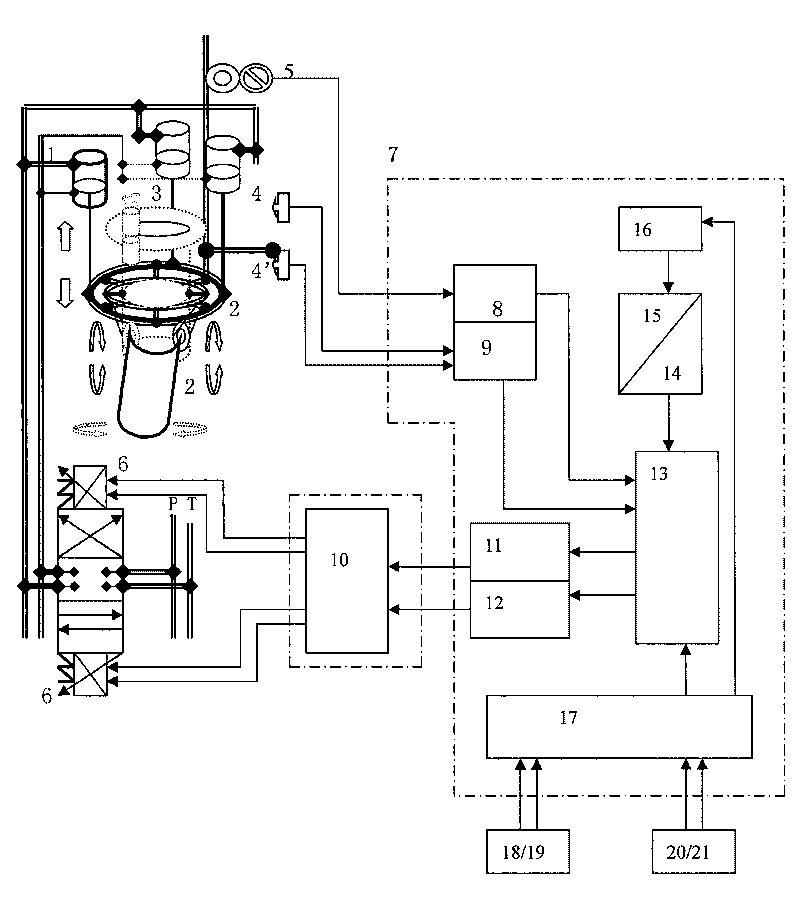

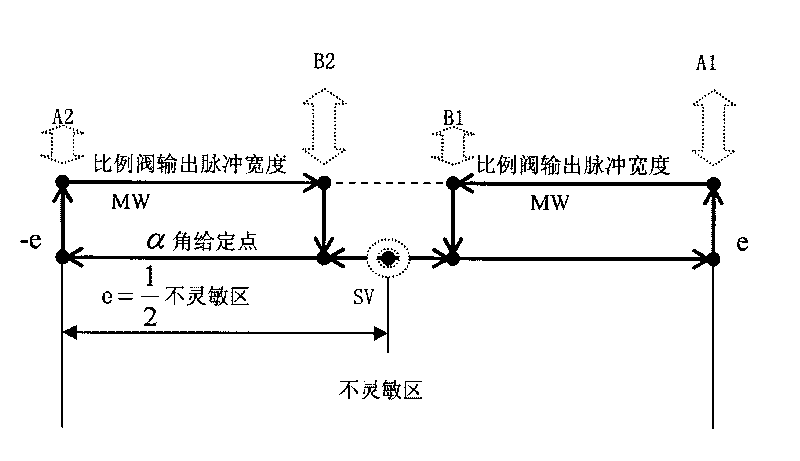

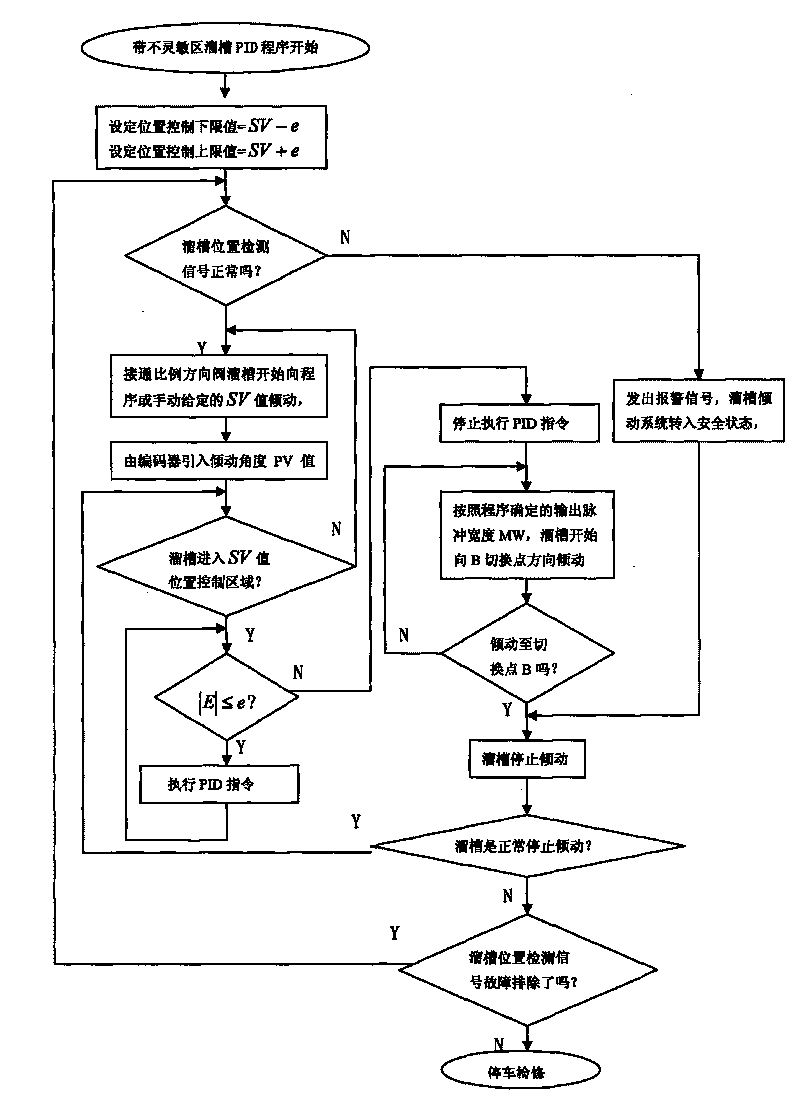

[0031] Such as figure 1 As shown, the blast furnace bellless top chute auxiliary transmission inclination automatic control device of the invention of the present method comprises the following components:

[0032] Linear oil cylinder 1 is used to drive the inclination angle (α angle) of the secondary transmission of the chute. The linear oil cylinder 1 is connected to the output end of the proportional directional valve 6, and is used to drive the chute to tilt under the control of the proportional directional valve 6. The linear oil cylinder 1 makes the chute 2 swing , until reaching the tilting set angle;

[0033] The chute rotary motor 3 is used to rotate the chute, and the rotary motor 3 is also connected to the output end of the proportional directional valve 6, and drives the chute to rotate under the control of the proportional directional valve 6;

[0034] Proportional directional valve 6, the output end is connected with linear oil cylinder 1 and rotary motor 3 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com