Bevel ratchet wheel compensating device

A compensating device, bevel ratchet technology, applied in the direction of overhead lines, etc., can solve the problems of inflexible rotation of the ratchet, small tension resistance of the compensation rope, and small compensation distance, so as to achieve reliable comprehensive braking performance and improve safety margins. degree, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

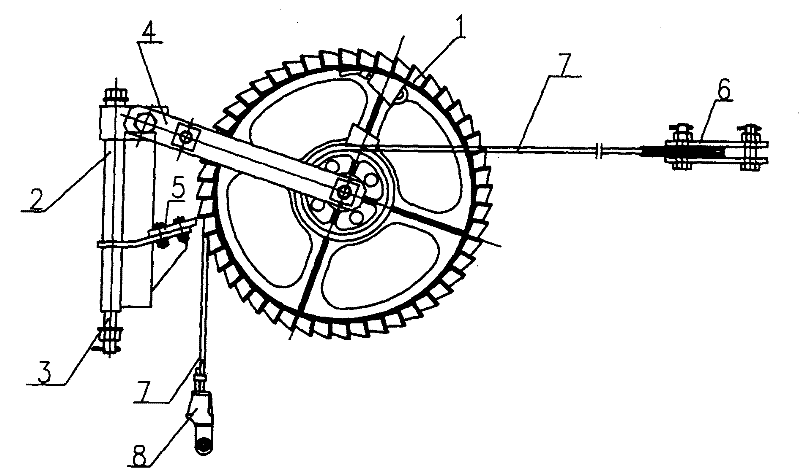

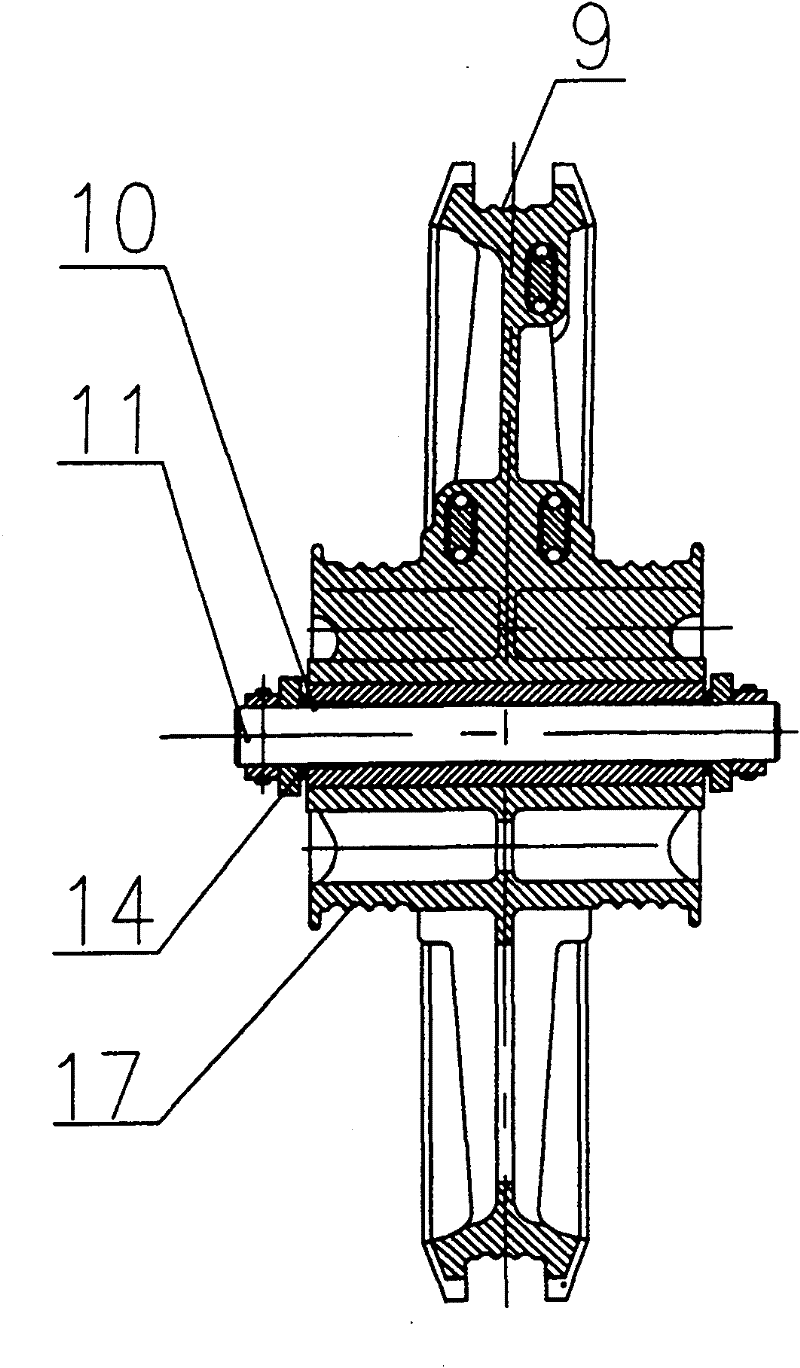

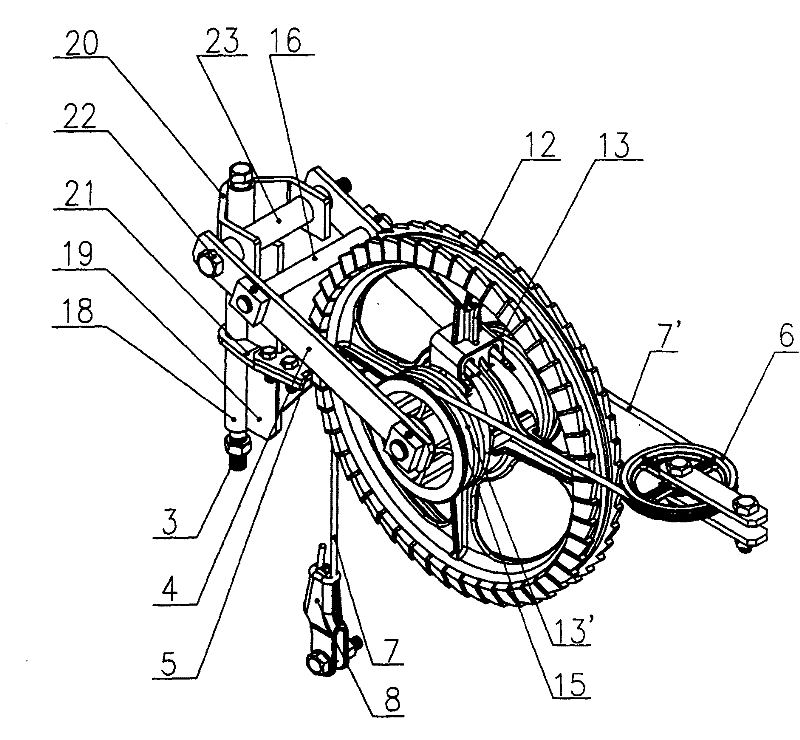

[0024] combined with figure 1 , 2 , 3, 4, 5, 6 describe an embodiment of the present invention.

[0025] A bevel tooth ratchet compensating device, comprising a ratchet body 1, a ratchet brake frame 2, a long bolt pin 3, a ratchet frame connecting plate 4, a brake clamp 5, a balance wheel 6, a steel wire rope I 7, a steel wire rope II 7' and a double Ear wedge clip 8. The ratchet body 1 is installed on the ratchet shaft 11 through a pair of flanging copper-based self-lubricating sliding bearings 10, and the flanging is located on the outside. The two ends of the ratchet shaft 11 are fixed on the front end of the ratchet frame connecting plate 4, and the two ends of the ratchet shaft 11 are equipped with end face self-lubricating bearings 14, and the end face self-lubricating bearings 14 are located between the ratchet frame connecting plate 4 and the self-lubricating sliding bearing 10 , when the ratchet body deviates so that the flanging of the self-lubricating sliding bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com