Process for producing anti-channel conflict packages for liquid products

A production process and anti-smuggling technology, which is applied in the packaging production process of bottled goods, can solve problems such as loss of confidence in dealers' product brands, irrational market structure, and out-of-control regional supply balance, and quickly identify infringing and counterfeit products , easy to judge and respond quickly, and the effect of solving the problem of cross-selling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

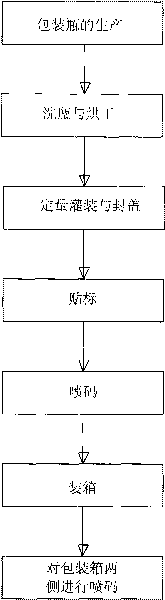

[0057] like figure 1 Shown, among the present invention, the packaging production technology of anti-fleeing goods of liquid product comprises the following steps:

[0058] The first step: the production of the wine bottle, a positioning part that can determine the position of the wine bottle is formed on the outer wall of the wine bottle. The positioning part in this embodiment is a card slot formed on the outer wall of the wine bottle. Of course, the card The grooves can also be replaced by other structures, such as bumps, bumps, pits, etc., which are set according to the structure and material of different packaging bottles, but are not limited thereto. Since the production of the card groove formed on the outer wall of the wine bottle can be realized only by simply improving the production mold according to the demand, and this is easy to realize in the field of wine bottle production, so no further description is given.

[0059] The second step: bottle washing and drying...

Embodiment 2

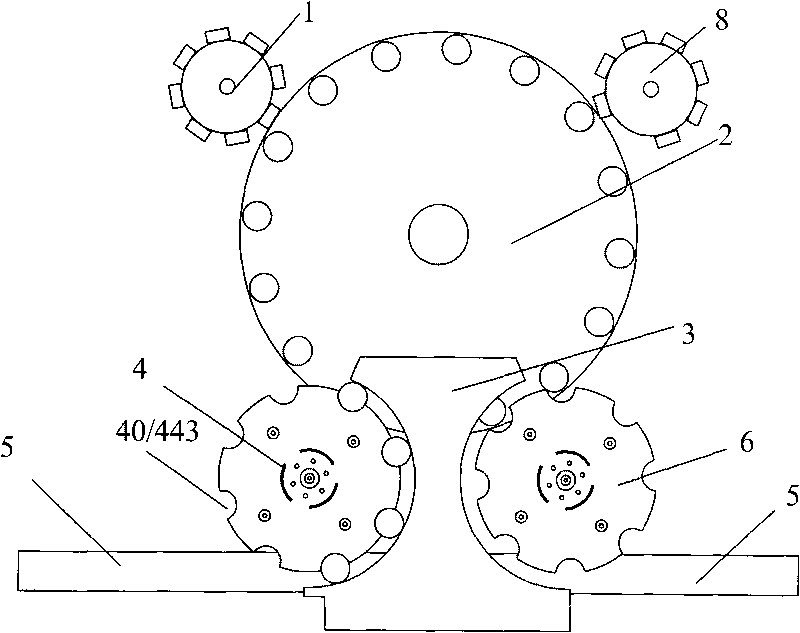

[0076] The packaging process in this embodiment is basically the same as that in the above-mentioned embodiment one, so the similarities will not be described again. path steps, such as Figure 12 As shown, the specific implementation process of the orderly lane separation step is as follows: arrange the wine bottles according to the size of the packaging box and the arrangement relationship of the wine bottles in the packaging. Taking 12 bottles of wine in a packaging box as an example, the number of wine bottles The arrangement relationship is a 4*3 arrangement relationship, that is, input 4 wine bottles in order in each row, and place them in 3 rows. For this reason, 12 bottles of wine can be packed into the packing box at one time by directly using 12 grabbing devices 111 inside, such as Figure 10 shown. Since each wine bottle is sprayed with a unique first code, in order to ensure the orderliness of each wine bottle, a wine bottle sorting device is provided on the conv...

Embodiment 3

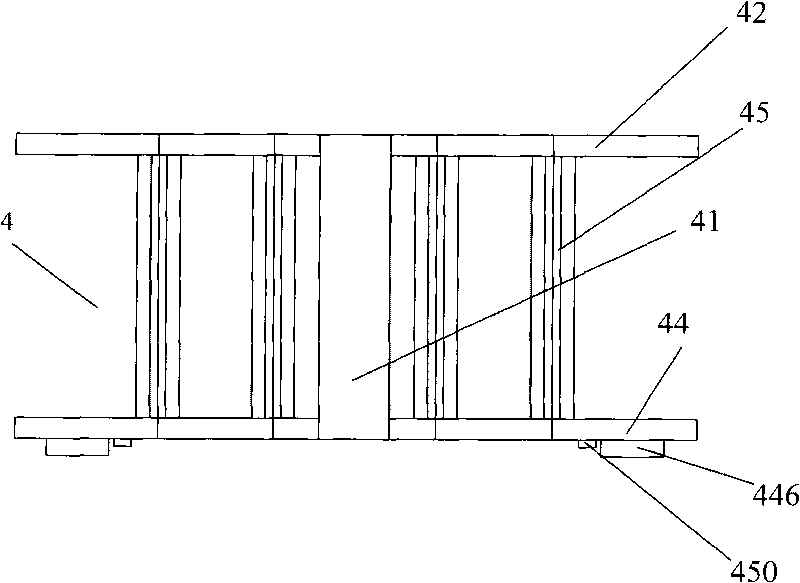

[0079] In this embodiment, on the basis of the above-mentioned embodiment two, an additional process step is added to spray the second code on the four sides of the packing box, such as Figure 13 As shown, due to the different stacking methods of the packaging boxes during transportation, if the second code is only sprayed on both ends, it may cause inconvenience in the transportation process. Therefore, it is necessary to spray the second code on the four sides of the packaging box. code, so that it can be conveniently transported, but the existing packaging production process can only spray codes on both ends of the packaging box. For this reason, the present invention adds a step to the other two sides of the packaging box Coding equipment, such as Figure 11 As shown, the side of the conveyor belt 5 behind the packing device 11 is provided with a push rod 121 through the support 12, that is, a box blocking device. When the packing box is in the transportation process, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com