Volume stabilizer of free calcium oxide as well as preparation and application thereof

A free calcium oxide and stabilizer technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve environmental pollution problems, achieve the effects of reducing pollution, reducing costs, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

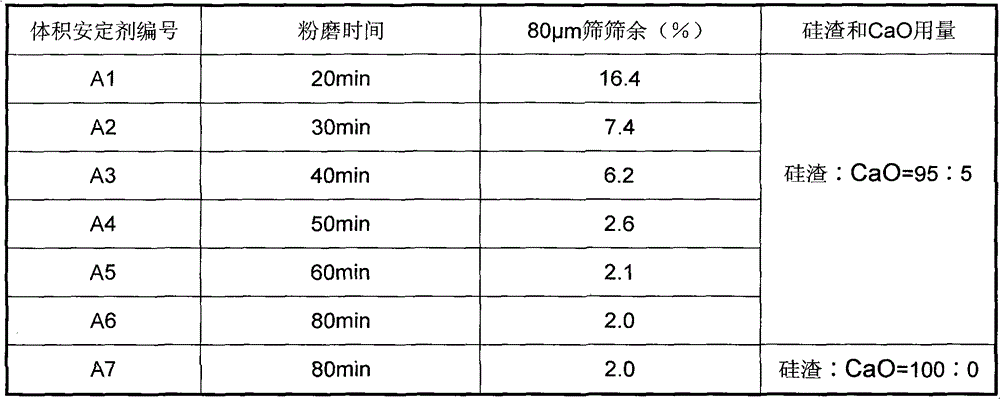

[0028] Take silicon slag (produced by Shanghai Waigaoqiao Petrochemical Plant), and dry it in an oven at a temperature of 100±5°C for 24 hours. Get dried silicon slag 950g and 50g CaO (analytically pure), and dried silicon slag 1000g, respectively grind 20-80min in laboratory standard mill (Φ50×50cm) (Shanghai building material instrument factory production), obtain free Calcium oxide volume stabilizer, according to GB / T 1345-2005 "Cement fineness test method sieve analysis method", determine the sieve residue of 80μm, see Table 2.

[0029] Table 2

[0030]

Embodiment 2

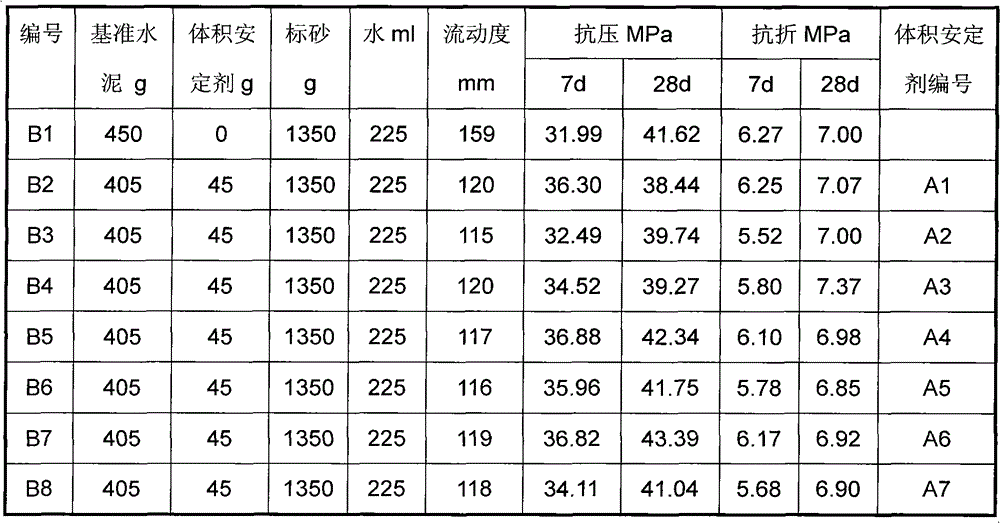

[0032] For free calcium oxide volume stabilizers of different finenesses, use the internal blending method to mix with reference cement, and replace 10% cement with equal mass (that is, the weight ratio of free calcium oxide volume stabilizers in the cementitious material is 10%), water The gray ratio is 0.5, and the strength test is carried out according to "Cement mortar strength test method (ISO method)) GB / T17671-1999. For B2 to B8, see Table 3 for the experimental results.

[0033] table 3

[0034]

[0035] It can be seen from Table 3:

[0036] (1) When the 80 μm sieve residue of the free calcium oxide volume stabilizer is 1-3%, the 7-day and 28-day compressive strength can exceed the benchmark cement, indicating that the free calcium oxide volume stabilizer has higher activity.

[0037] (2) Comparing the experimental results of groups B7 and B8, adding CaO to modify the silicon slag can improve the strength to a certain extent.

Embodiment 3

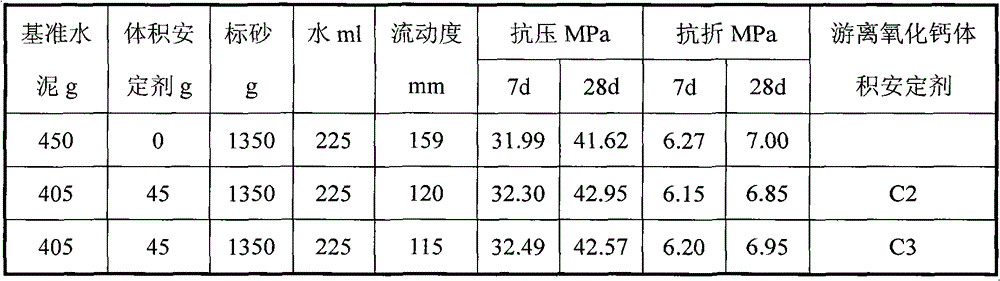

[0039] Take silicon slag (produced by Shanghai Waigaoqiao Petrochemical Plant), and dry it in an oven at a temperature of 100±5°C for 24 hours.

[0040] Get dried silicon slag 880g and mix with 120g anhydrous sodium metasilicate (chemically pure); Grind 50min in the laboratory standard mill (Φ50 * 50cm) (Shanghai building materials instrument factory production), obtain free calcium oxide volume stabilizer ( numbered C2).

[0041] Get dried silica slag 900g and 100g cement (P.O42.5) and mix, grind 50min in laboratory standard mill (Φ50 * 50cm) (Shanghai building materials instrument factory production), obtain free calcium oxide volume stabilizer (number is C3).

[0042] Adopt internal blending method to mix reference cement, replace 10% cement with above-mentioned free calcium oxide volume stabilizer respectively equal quality (the weight ratio of free calcium oxide volume stabilizer in cementitious material is 10%), water-cement ratio is 0.5, according to the "cement morta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com