Process for producing dry powder mortar gelling agent by using acetylene sludge

A dry powder mortar and production process technology, applied in cement production and other directions, can solve the problems of poor quality of lime, high rate of raw overburning, volume of blasting ash, etc., and achieve the effects of rational utilization, simple production process and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

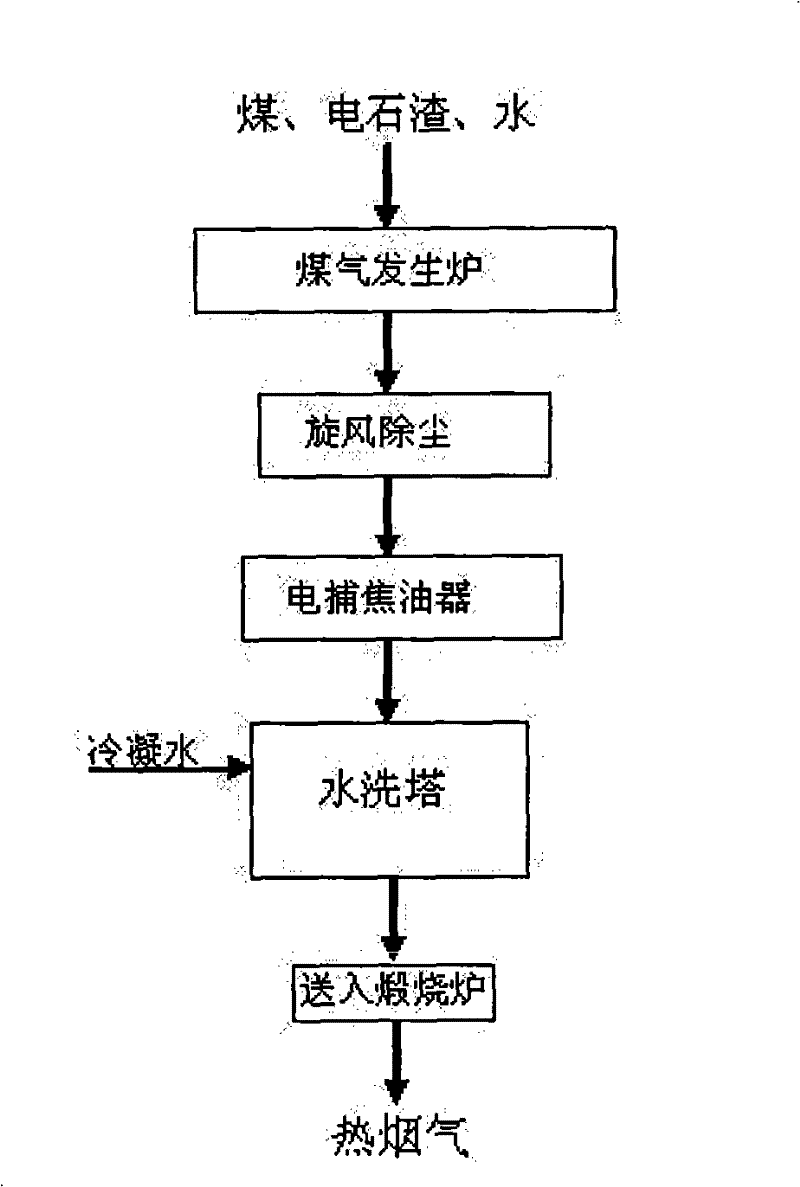

[0023] Such as figure 1 The hot flue gas production process flow chart shown above shows that the hot flue gas comes from the calciner, specifically: the project adopts a two-stage gas generator, and the gas produced is subjected to cyclone dust removal and electric tar capture, then enters the water washing tower and is washed with water. , into the calciner in the production workshop to provide hot flue gas for the production of the dry powder mortar gelling agent in this embodiment. The project uses coal mixed with calcium carbide slag for desulfurization, the calcium-sulfur ratio (weight) is 1:5, and the desulfurization efficiency is about 60%.

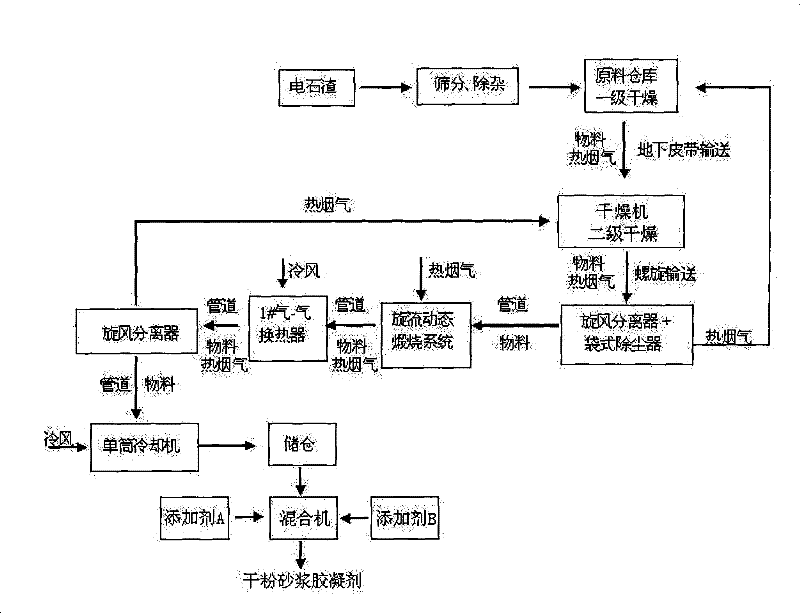

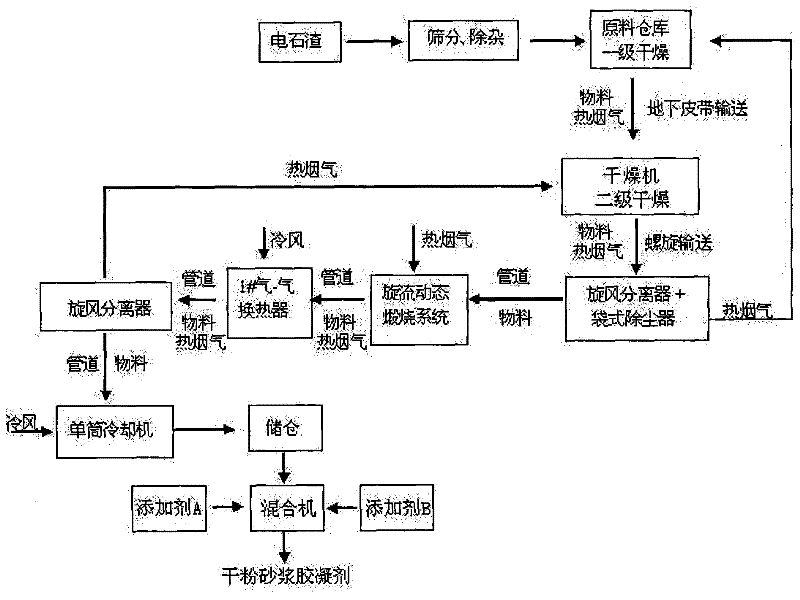

[0024] Such as figure 2 The production process flow chart of using calcium carbide slag to prepare dry powder mortar gelling agent is shown: because the carbide slag contains a large amount of impurities, the particle size distribution of the impurities is wide, and it is not easy to separate. Before the carbide slag enters the ...

Embodiment 2

[0026] The material after the secondary cooling is sent into the mixer through the conveying device, and after being evenly mixed with the additive in a weight ratio of 1:3, it is the finished product of the dry powder mortar gelling agent, wherein the additive in this embodiment is fly ash / slag / The composition of zeolite powder, in the composition, fly ash: slag: zeolite powder=1: 1: 1 (weight ratio);

Embodiment 3

[0028] The material after the secondary cooling is sent into the mixer through the conveying device, and after being uniformly mixed with the additive at a weight ratio of 1:5, it is the finished product of the dry powder mortar gelling agent, wherein the additive in this embodiment is fly ash / slag / The composition of zeolite powder, in the composition, fly ash: slag: zeolite powder=2: 1: 2 (weight ratio);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com