Evaporation coating method of films for aluminum thickened metalized capacitors

A technology for thickening metals and capacitors, applied in the direction of thin film/thick film capacitors, multilayer capacitors, etc., to achieve the effect of long storage period, strong moisture resistance, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

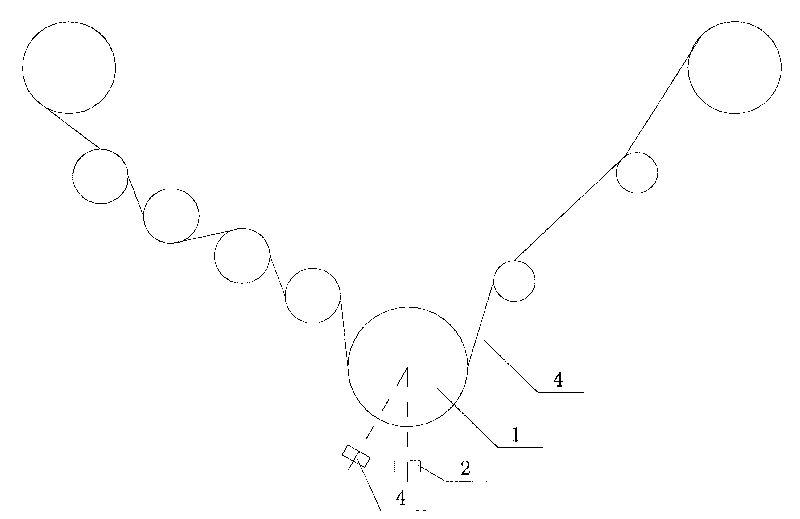

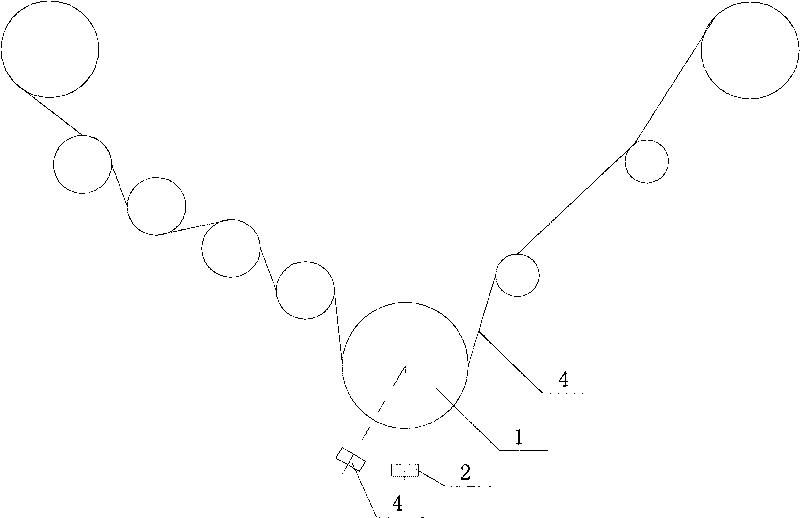

[0012] see figure 1 , an evaporation method for thin films for aluminum thickened metallized capacitors, comprising an evaporation aluminum film step and an aluminum reinforcement layer evaporation step, the aluminum evaporation step and the evaporation zinc reinforcement layer step are in the same vacuum system, once Completed. The connection between the first aluminum crucible 2 used in the evaporation aluminum film step and the main roll 1 of the evaporation machine and the connection between the second aluminum crucible 3 used in the step of evaporating the aluminum reinforcement layer and the main roll 1 of the evaporation machine The angle between the connecting lines is 40-50 degrees, and the better angle is 45 degrees. Controlling this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com