Vacuum evaporating coating machine of films for aluminum thickened metalized capacitors

A technology of thickening metal and vacuum evaporation, which is applied in the direction of thin film/thick film capacitors and laminated capacitors, etc., can solve the problems of inability to process thin films for aluminum thickened metallized capacitors, and achieve long storage period, strong moisture resistance, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

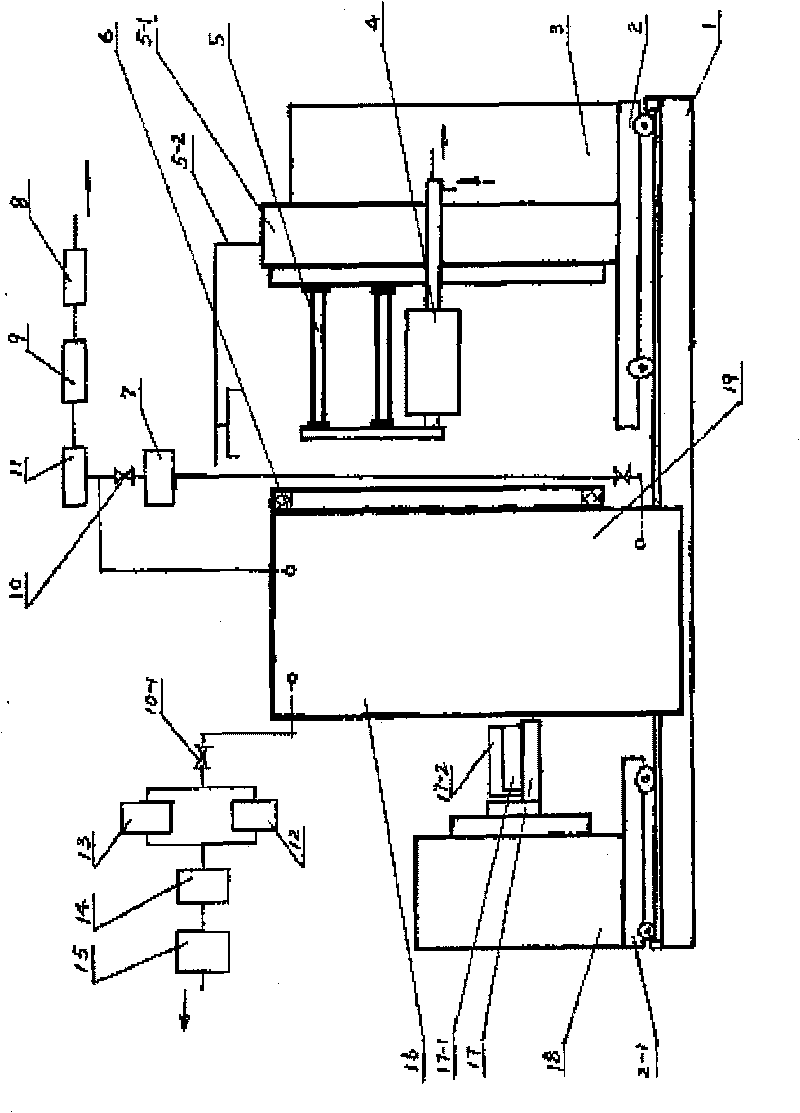

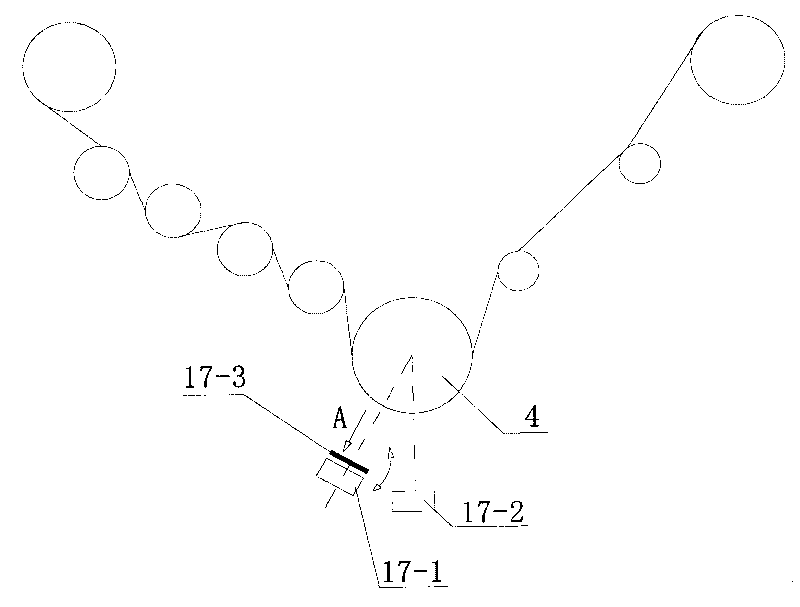

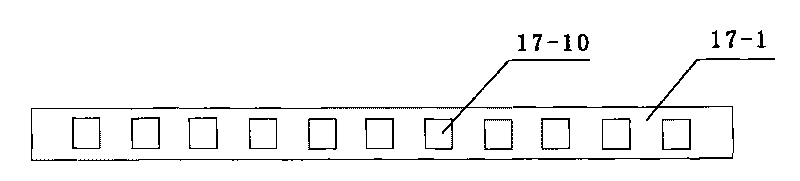

[0014] see figure 1 , a vacuum evaporation coating machine for aluminum thickened metallized capacitor film, the whole machine controlled by computer is located on the bottom frame 1, and the bottom frame 1 is provided with tracks, and the rollers of the main frame 2 can be seated on the bottom frame. The freezing frame 3 on the main frame 2, the winding system casing 5-1 connected to the freezing frame 3, and the main shaft 4 and winding system 5 arranged on the winding system casing 5-1 move along the track. The two sides of the vacuum chamber 6 are open, and the inside is divided into two parts: a winding chamber 16 and a coating chamber 19. The vacuum chamber 6 is fixed on the chassis 1, and the opening of the winding chamber 16 of the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com