Method and system for calibrating standard colorimetric plate for cotton colorimeter

A calibration method and a calibration system technology, applied in the direction of color measurement devices, etc., can solve the problems of not reflecting the overall situation of the swatches, affecting the accuracy of swatch calibration, etc., to achieve uniform and stable optical signals, improve accuracy, and accurate swatch calibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

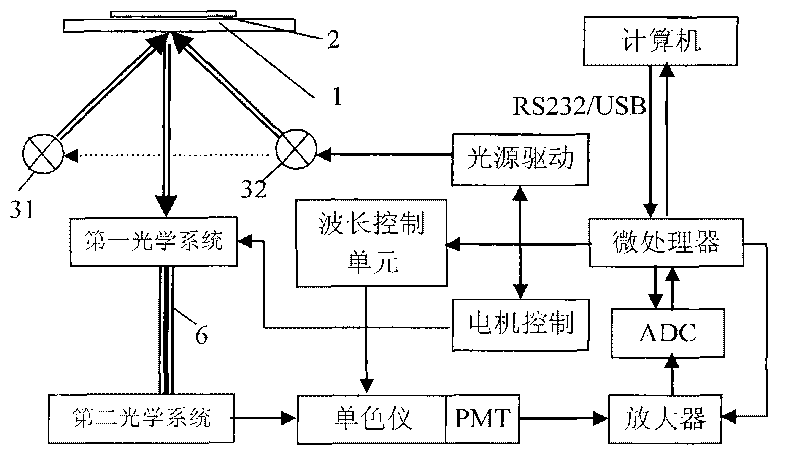

[0043] Refer to attached picture. The calibration system of the cotton color meter standard color plate provided by the present invention comprises:

[0044] Microprocessor, the microprocessor first assumes the control of the wavelength scanning of the monochromator in the system, the functions of gain control, signal sampling and data communication with the computer; further, the microprocessor can also undertake the first optical system and test The distance control of the swatch placement position on the table, and the light intensity control of the visible light source.

[0045] The test bench 1 of the color board 2 is provided with a place for placing the color board.

[0046] Symmetrical visible light sources 31 and 32 with an irradiation angle of 45° to the position of the calibration color plate on the fixing mechanism.

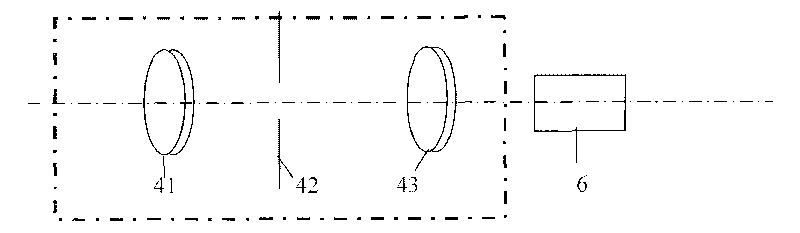

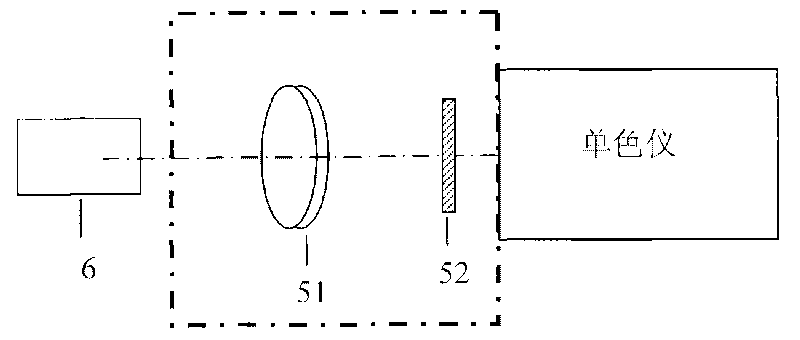

[0047]The first optical system that focuses the reflected light of the color plate to be calibrated at an angle of 0° with the position of the colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com