Helmholtz coil-based electric conductivity nondestructive measurement system

A Helmholtz coil and measurement system technology, applied in the direction of material resistance, can solve the problems of positioning, resolution limitation, uneven magnetic field, shallow measurement depth, etc., achieve high resolution, increase information extraction, and improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 The specific construction of the system

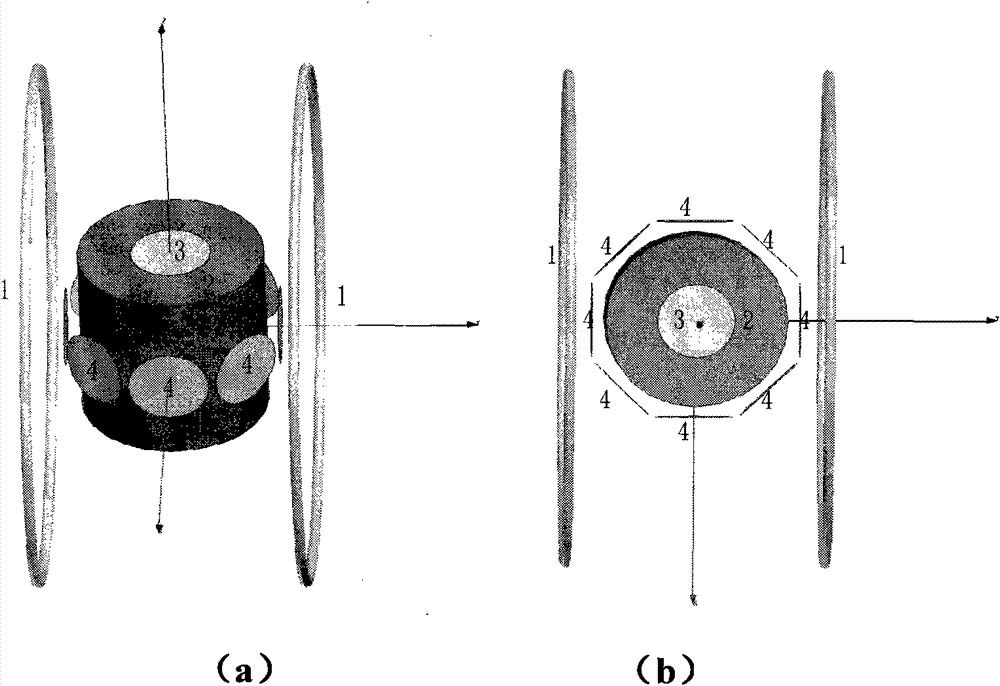

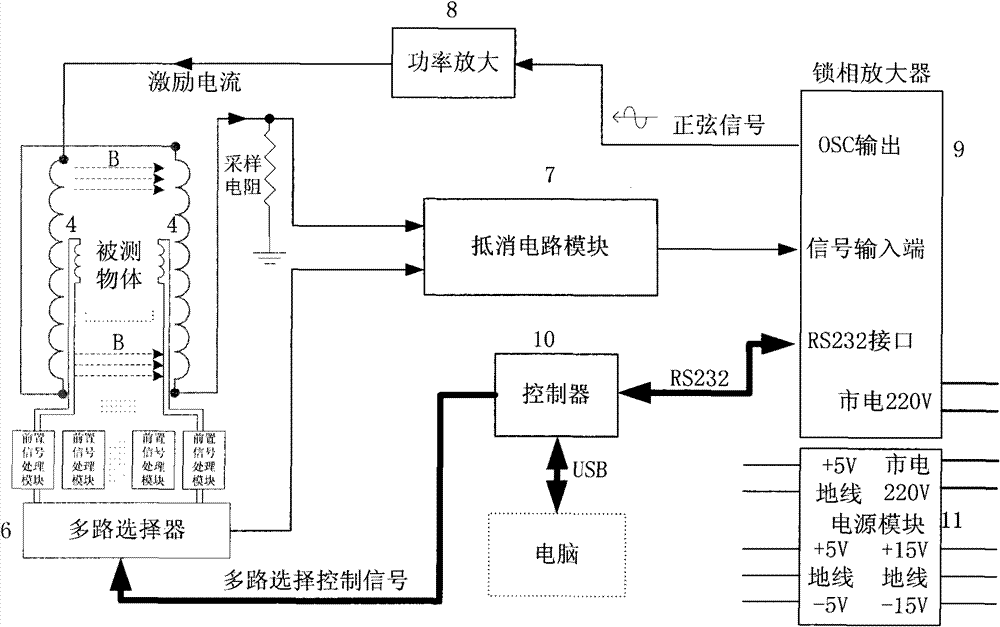

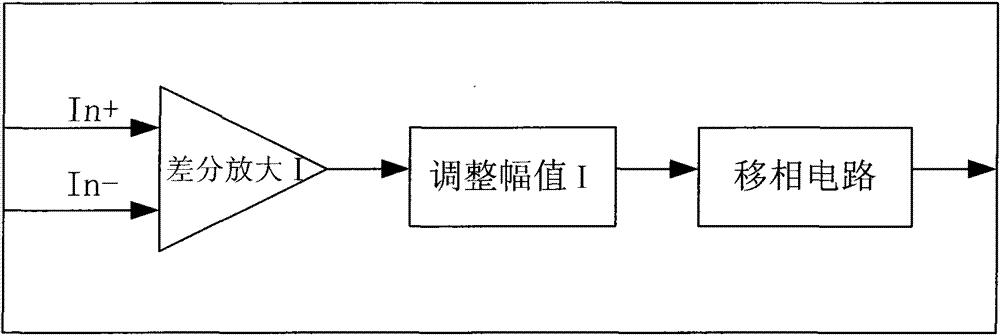

[0027] See attached figure 2 : the present invention comprises Helmholtz coil 1, detection coil 4, offset circuit, lock-in amplifier, controller and power supply, wherein:

[0028] 1) A time-varying uniform magnetic field B is constructed by the Helmholtz coil 1. In the embodiment, the parameters of the Helmholtz coil 1 are: inductance 67uH, DC impedance 234.8mΩ and distributed capacitance 3.7pF;

[0029] 2) In the above-mentioned uniform magnetic field, a number of detection coils 4 that can cut the magnetic force line are arranged in a single or annular interval; several coils are arranged around the ring, and the spacing of the coils can be adjusted according to different resolutions. If you want to locate the object For the damaged position, several coils should be arranged around the object. The more coils, the better the positioning effect; if it is only necessary to detect whether the object has cracks, it...

Embodiment 2

[0036] Embodiment 2 Comparison of the traditional system and the excitation magnetic field of the present invention

[0037] See attached Figure 6 , this is the magnetic field distribution diagram of the unilateral excitation coil of the traditional system. The magnetic field strength at the initial point is 0.0003T; at a distance of 10mm, the magnetic field strength is 0.00008T; at a distance of 20mm, the magnetic field strength is 0.00002T; at a distance of 25mm The magnetic field is already close to zero. It can be seen that the effective measurement distance of the traditional system is relatively shallow, and the magnetic field decays very quickly, and the magnetic field below 10mm is very weak.

[0038] See attached Figure 7 , the distribution diagram of the excitation magnetic field produced by the Helmholtz coil 1 of the present invention on the central axis, the magnetic field strength at its initial point is 0.000166T; the magnetic field strength at a distance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com