Method for producing straw

A production method and technology for straws, which are applied to table utensils, home utensils, table utensils, etc., can solve the problems of straw pollution, large space occupation, top cup cover, etc., and achieve the effects of easy operation, small space occupation, and safety and hygiene guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of production method of drinking straw, it comprises the following steps:

[0030] (1) Color matching: mix and match plastic powder and pigments to obtain raw materials;

[0031] (2) Small tube production: the raw material is drawn into a small straight tube with an inner diameter of 8 mm and a wall thickness of 0.28 mm after hot melting, and cut into a small tube with a length of 102 mm;

[0032] (3) Production of large tube: the raw material is drawn into a large straight tube with an inner diameter of 10 mm and a wall thickness of 0.23 mm after being melted, and cut into a large tube with a length of 94 mm;

[0033] (4) Large tube bending: the middle part of the large tube is made into a flexible structure, so that the large tube can be bent into 90 degrees;

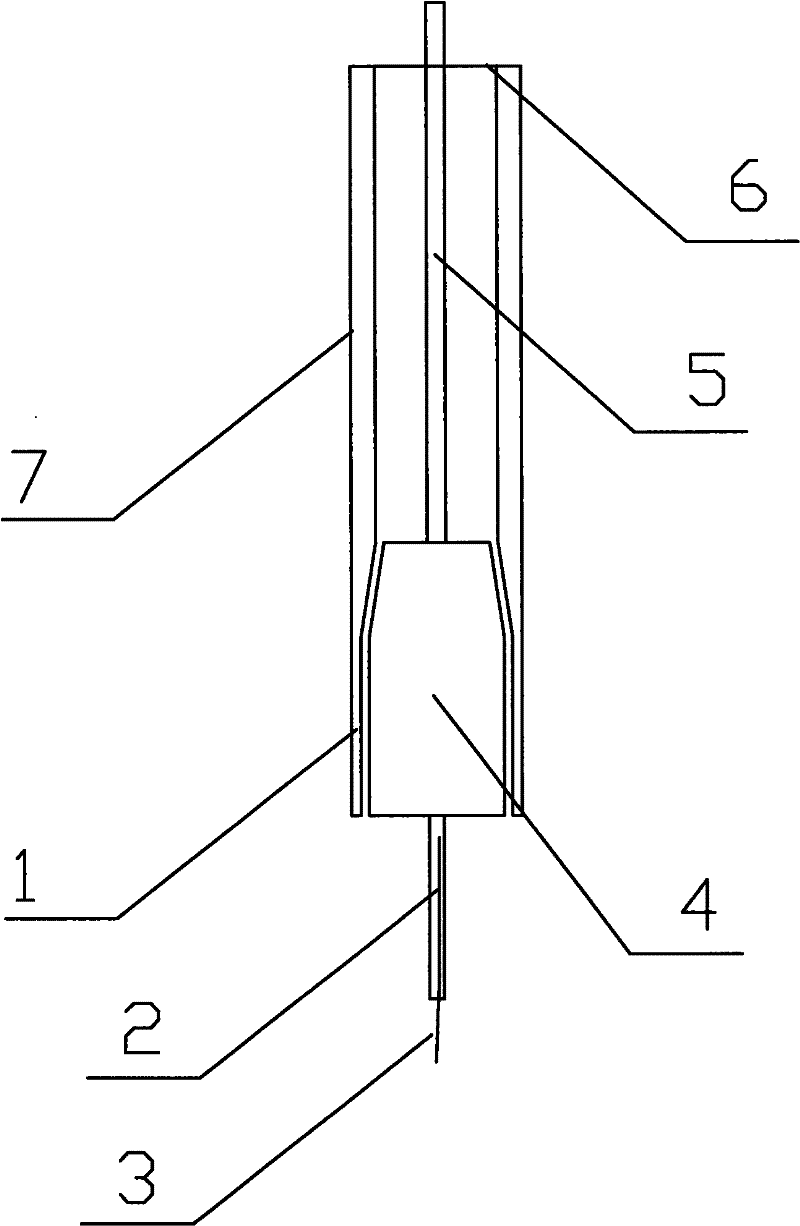

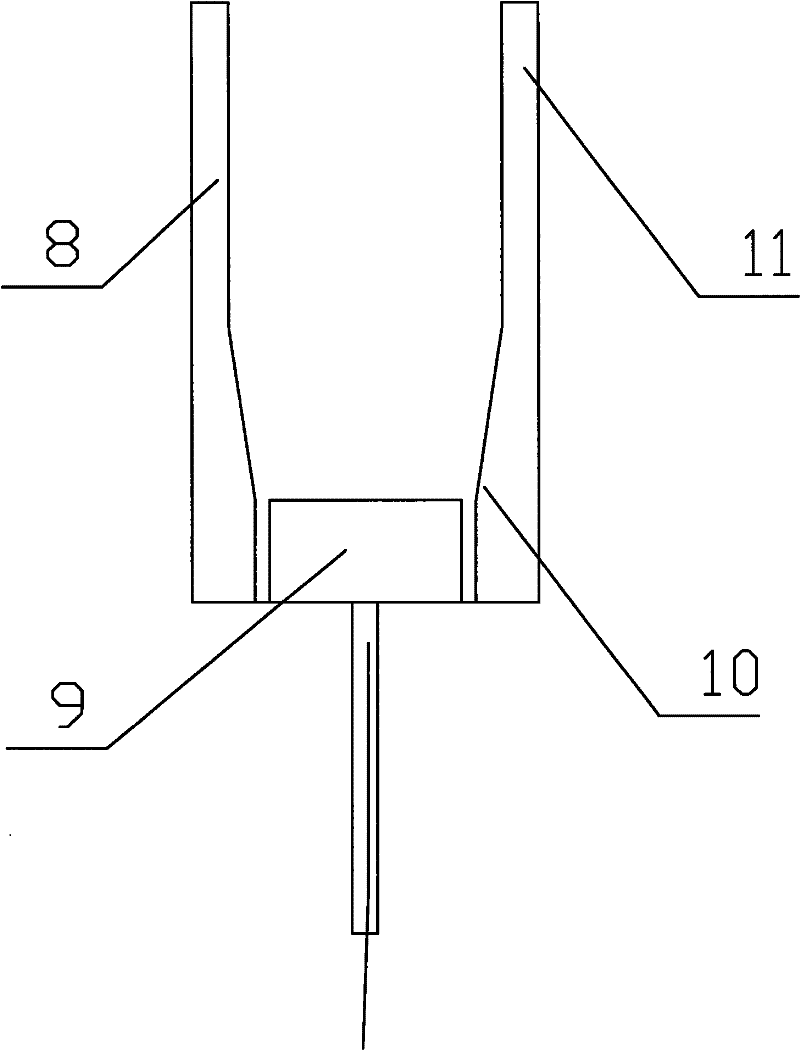

[0034] (5) Small tube flaring step: put the small tube into the flared seat 7, place one end of the small tube at the flared position 1 of the flared seat 7, and simultaneously place the conical tube th...

Embodiment 2

[0039] A kind of production method of drinking straw, it comprises the following steps:

[0040] (1) Color matching: mix and match plastic powder and pigments to obtain raw materials;

[0041] (2) Small tube production: the raw material is drawn into a small straight tube with an inner diameter of 8.4 mm and a wall thickness of 0.32 mm after hot melting, and cut into a small tube with a length of 102 mm;

[0042] (3) Production of large tubes: the raw materials are drawn into large straight tubes with an inner diameter of 10.4 mm and a wall thickness of 0.27 mm after thermal melting, and then cut into large tubes with a length of 94 mm;

[0043] (4) Large tube bending: the middle part of the large tube is made into a flexible structure, so that the large tube can be bent into 120 degrees;

[0044] (5) Small tube flaring step: put the small tube into the flared seat 7, place one end of the small tube at the flared position 1 of the flared seat 7, and simultaneously place the c...

Embodiment 3

[0049] A kind of production method of drinking straw, it comprises the following steps:

[0050] (1) Color matching: mix and match plastic powder and pigments to obtain raw materials;

[0051] (2) Small tube production: the raw material is drawn into a small straight tube with an inner diameter of 8.2 mm and a wall thickness of 0.3 mm after thermal melting, and cut into a small tube with a length of 102 mm;

[0052] (3) Production of large tubes: the raw materials are drawn into large straight tubes with an inner diameter of 10.2 mm and a wall thickness of 0.25 mm after thermal melting, and then cut into large tubes with a length of 94 mm;

[0053] (4) large tube bending: the middle part of the large tube is made into a flexible structure, which can make the large tube bend into 105 degrees;

[0054](5) Small tube flaring step: put the small tube into the flared seat 7, place one end of the small tube at the flared position 1 of the flared seat 7, and simultaneously place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com