A kind of catalyst for preparing aldehyde by two-phase catalytic hydroformylation reaction and its application

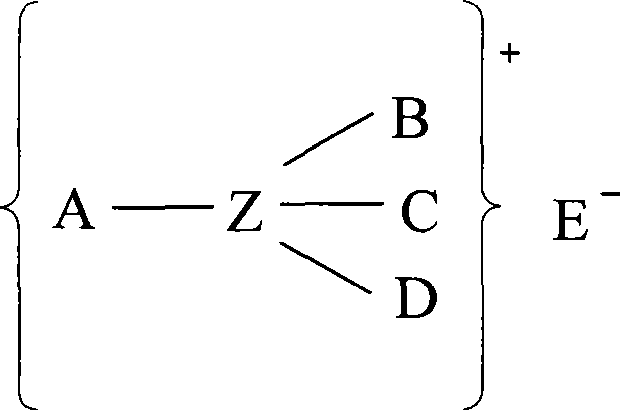

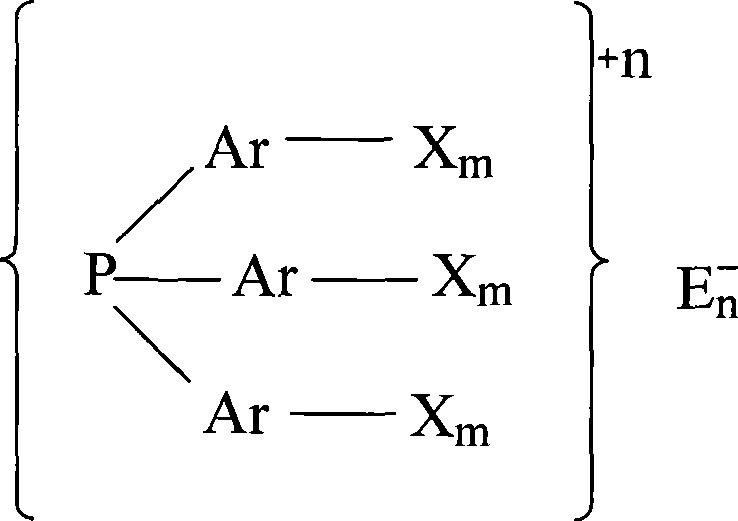

A technology for catalyzing hydroformyl and catalysts, which is applied in the preparation of carbon monoxide reactions, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. It can solve the problems of low reaction rate, increased rhodium catalyst loss, and phase separation Difficulties and other problems, to achieve the effect of reducing the loss of rhodium in the organic phase and eliminating emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Put 25ml of a mixed solvent with a volume ratio of ethanol and water of 1:1 into a 100ml stainless steel autoclave, and weigh a certain amount of RhCl 3 ·xH 2 Add O and TPPTS ligands into the reactor so that the rhodium concentration in the alcohol-water solution is 0.01mol / L, the concentration of TPPTS is 0.075mol / L, and the molar ratio of TPPTS to rhodium is 7.5:1. Add 5ml of α-decene to the reaction kettle, and the volume ratio of water and organic phase in the reaction system is 5:1. With CO:H 2 = After replacing the air in the reactor with 1:1 synthesis gas, raise the reaction pressure to 4.0MPa, and raise the temperature to 100°C, and react at constant pressure for 2 hours. The temperature was lowered to 25° C., and the reaction solution was taken out. The interface between the two phases was clear without any emulsification. Two phases are separated by separating funnel, and the organic phase product is analyzed by N6890 gas chromatography to show that the con...

Embodiment 2~5

[0060] Change the volume ratio of ethanol-water solvent to 1:4 (Example 2), 8:17 (Example 3), 2:3 (Example 4), 3:2 (Example 5). The rest were prepared according to the method described in Example 1, and the organic phase product composition and rhodium content were analyzed after the reaction. The results are shown in Table 1.

[0061] Table 1 embodiment 2-5, the reaction system of different alcohol water volume ratio

[0062]

Embodiment 6~7

[0067] Change the volume ratio of ethanol-water solvent to be 2:3, and change the molar concentration of rhodium to be 0.0025mol / L (embodiment 6) and 0.005mol / L (embodiment 7) respectively, all the other prepare ten according to the method for embodiment 1 One aldehyde. After the reaction, the transformation rate of α-decene is respectively 94% (embodiment 6) and 95% (embodiment 7), and the undecanal selectivity is respectively 91% (embodiment 6) and 93% (embodiment 7), The anisotropic ratios of aldehydes were 2.7 (Example 6) and 2.7 (Example 7) respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com