Aluminum alloy water meter case die-casting and molding technology and product thereof

A water meter case and die-casting molding technology, which is applied in the field of aluminum alloy products, can solve the problems of high cost, high consumption, and non-anodization of copper products, and achieve the effects of good corrosion resistance, good sealing, and low possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The raw materials are formulated as follows:

[0069] Mg 40kg, Mn 7kg, Fe 4kg, Cr 1kg, Al 948kg, put various raw materials into the crucible boiler, and melt them to a liquid state at a temperature of 620-650°C; Inject into the cavity, die-cast under 180T pressure, die-cast according to the existing technology, take out the mold and take the blank; take out the mold from the blank and insert it into the mold; - remove the blank head; blank heat treatment process: use industrial RQ3 resistance furnace, put the blank , start the power supply, heat up to 520 ° C and keep the temperature for 3.00 hours - enter the water between 20-80 ° C for rapid cooling, this process is completed within 15 seconds from the furnace to the water; then put the processed blank into the industrial resistance furnace - well The furnace is kept at 170°C for 8 hours to achieve uniform molecular structure of the material, eliminate stress and improve hardness, which meets the requirements of turni...

Embodiment 2-8

[0072] Production technology is as embodiment 1, and formula is as shown in the table below:

[0073]

Embodiment 9

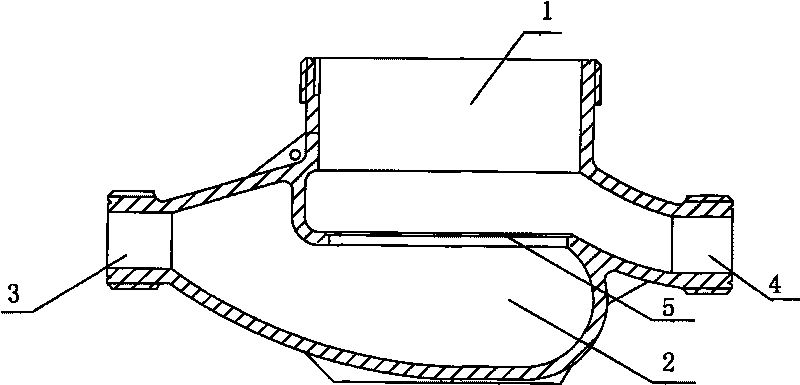

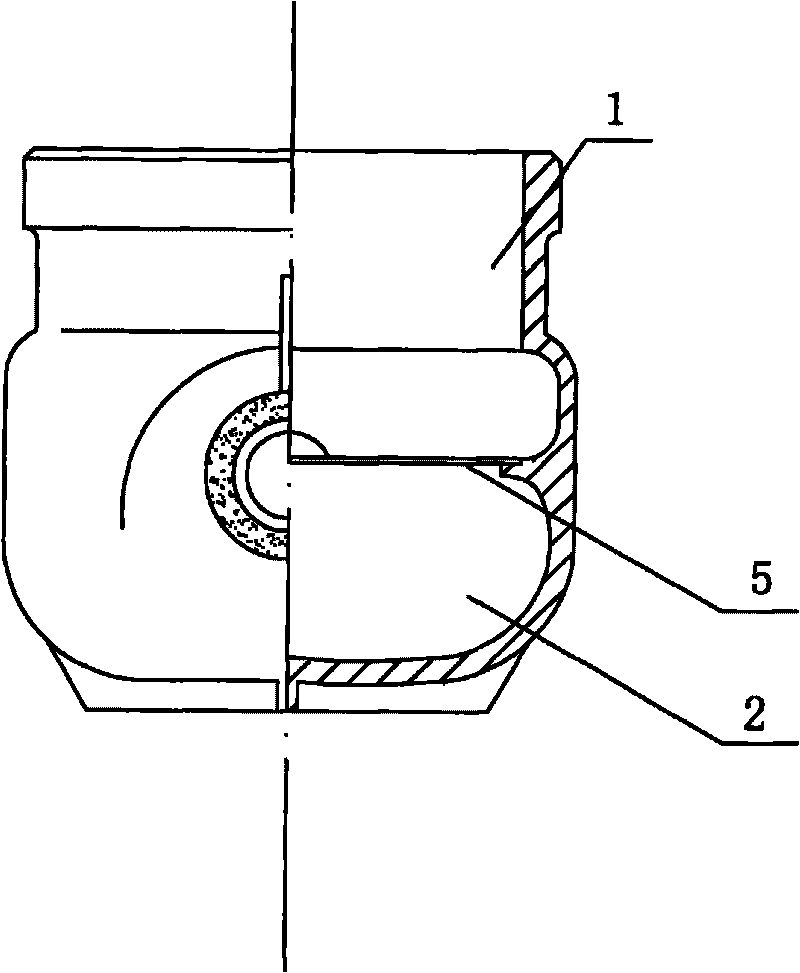

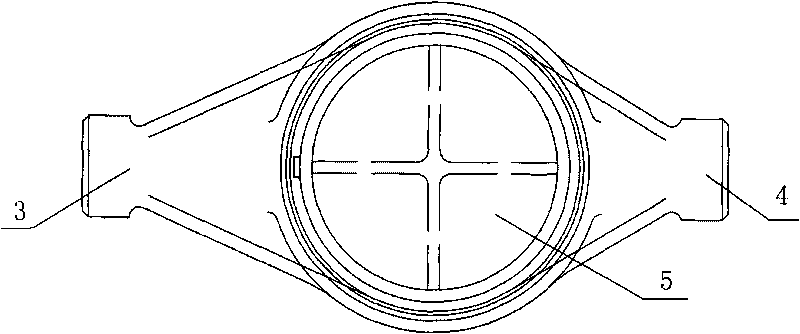

[0075] combine Figure 1-3 , an aluminum alloy water meter watch case, comprising an upper ring chamber 1, a lower ring chamber 2, a water inlet 3, and a water outlet 4, the water inlet 3 communicates with the lower ring chamber 2; the upper ring chamber 1 communicates with the water outlet 4 Connected; the upper ring chamber 1 is located above the lower ring chamber 2, and the movement of the water meter is divided into two mechanisms, namely, the metering mechanism and the counting mechanism. On the seat 5, the metering mechanism is located in the lower ring chamber 2, and the counting mechanism is located in the upper ring chamber 1.

[0076] The die-casting equipment of the present invention adopts 160T 180T 200T aluminum die-casting machine, its manufacturer Bengbu City Zhenhua Die-casting Machine Factory, J1118-J1175 type series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com