Method for forming structure

A molding method and structure technology, applied in the direction of stators, transmissions, pistons, etc., can solve the problems of many processes, low strength and reliability, high material and labor costs, and achieve simplified processes, thin body walls, and reduced consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

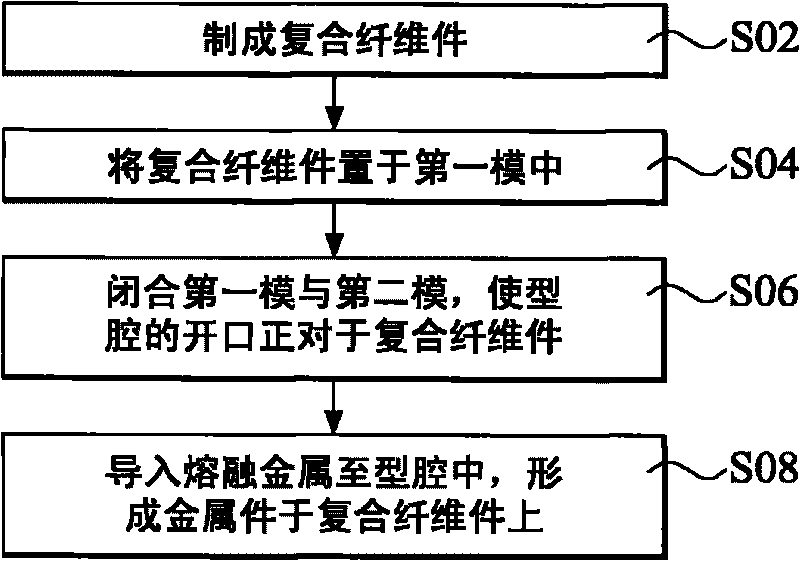

Method used

Image

Examples

Embodiment Construction

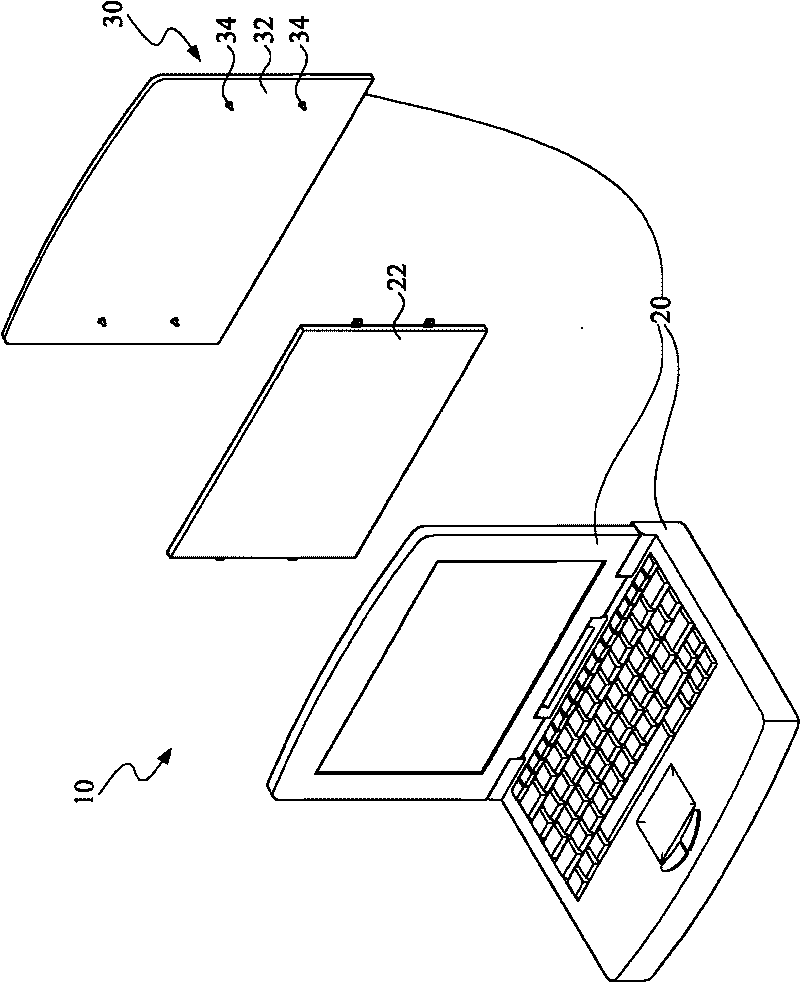

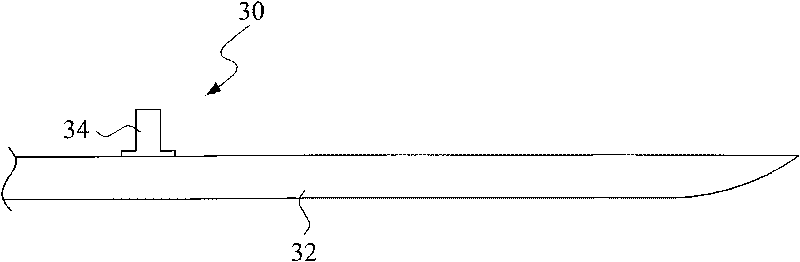

[0019] see figure 1 , figure 1 It is an exploded schematic diagram of the structure of 10 parts of the notebook computer. In a preferred embodiment, the structure 30 manufactured by the present invention can be applied to the shell 20 of a product, such as a notebook computer 10, a liquid crystal display, a smart mobile phone and other electronic products, or a packaging box, Non-electronic items such as furniture. figure 1 Taking the upper cover of the notebook computer 10 with the liquid crystal panel 22 as an example, the utilization of the structure 30 is described. The structure 30 includes an integrally formed composite fiber part 32 and a metal part 34, and the side of the composite fiber part 32 is opposite to the side where the metal part 34 is located. The other side (the outer side of the shell 20) is suitable as the surface of the shell 20. It has a special texture and touch in appearance, just like a hardcover ancient book. The metal piece 34 is convenient for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com