Multicolour photogravure method

A gravure printing, gravure printing machine technology, applied in printing, printing post-processing, printing devices, etc., can solve the problems of ink layer cracking, can not be used at the same time, affect the appearance of products, etc., to achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

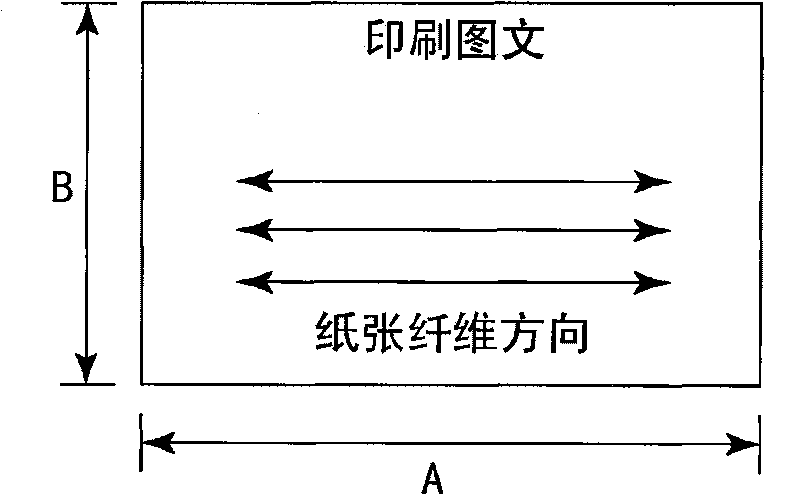

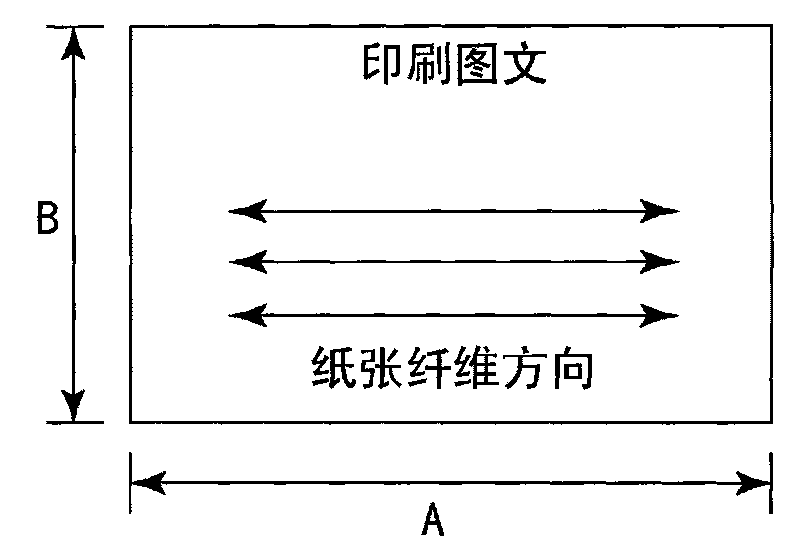

[0020] The multi-color gravure printing method is used to print water-based ink on aluminum-sprayed paper. The method is realized by a multi-color on-line gravure printing machine. The multi-color on-line gravure printing machine is composed of multiple printing color groups, and each printing color group One color of ink can be printed, and the graphic printing is completed after the paper passes through each printing color group in turn. So that the water-based ink just printed on the surface of the paper is dried and solidified on the surface of the paper before reaching the next printing color group. Generally, the drying system blows hot air to the paper to make the ink on the paper dry and solidify quickly. However, after the paper is heated, it is easy to expand along the direction perpendicular to the paper fiber, so it is easy to have overprint deviation dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com