Horizontal ozonizer

An ozone generator, horizontal technology, applied in the field of ozone generating devices, can solve the problems of increasing user operating costs, ozone cannot be output in time, unstable performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

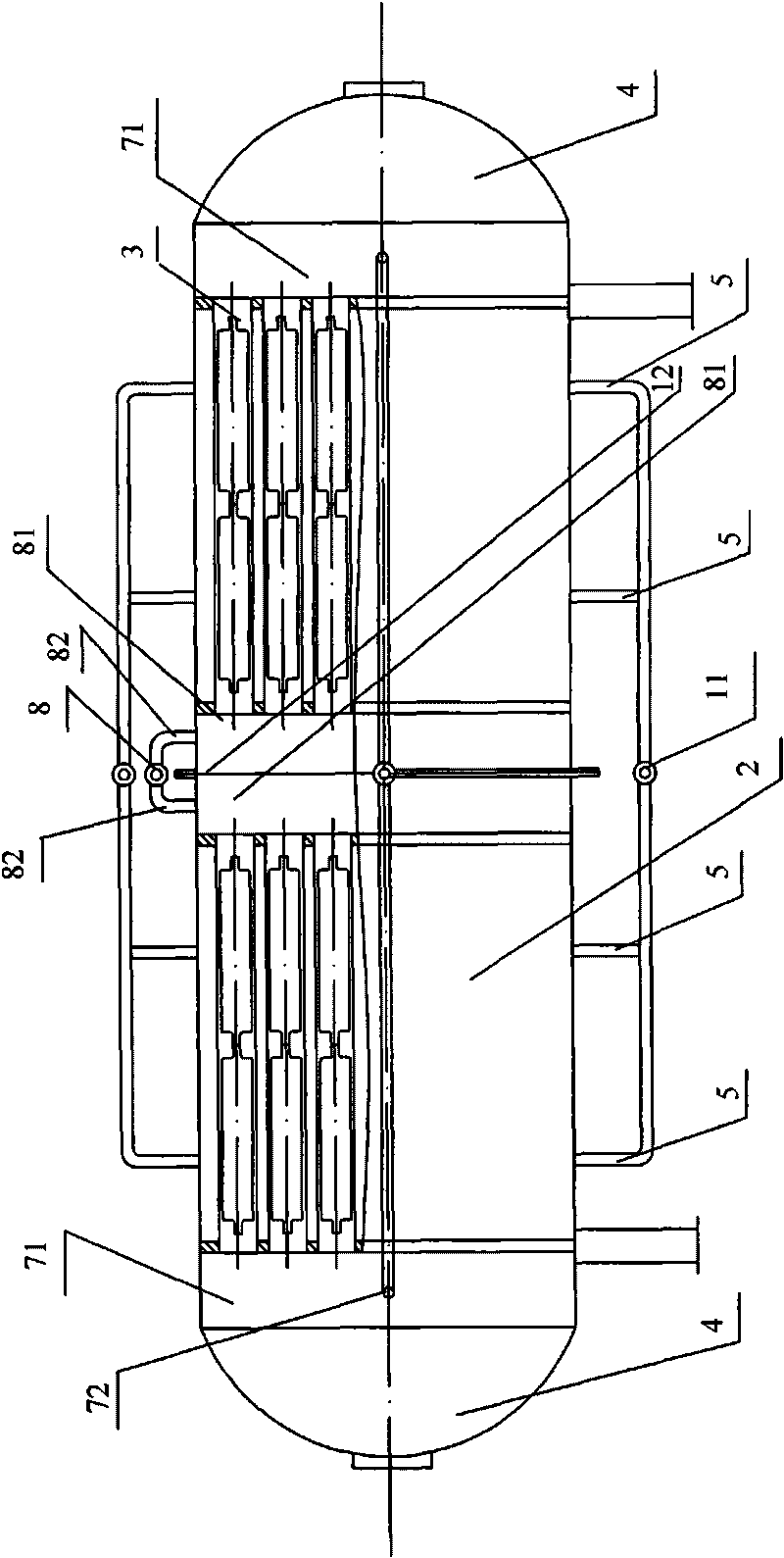

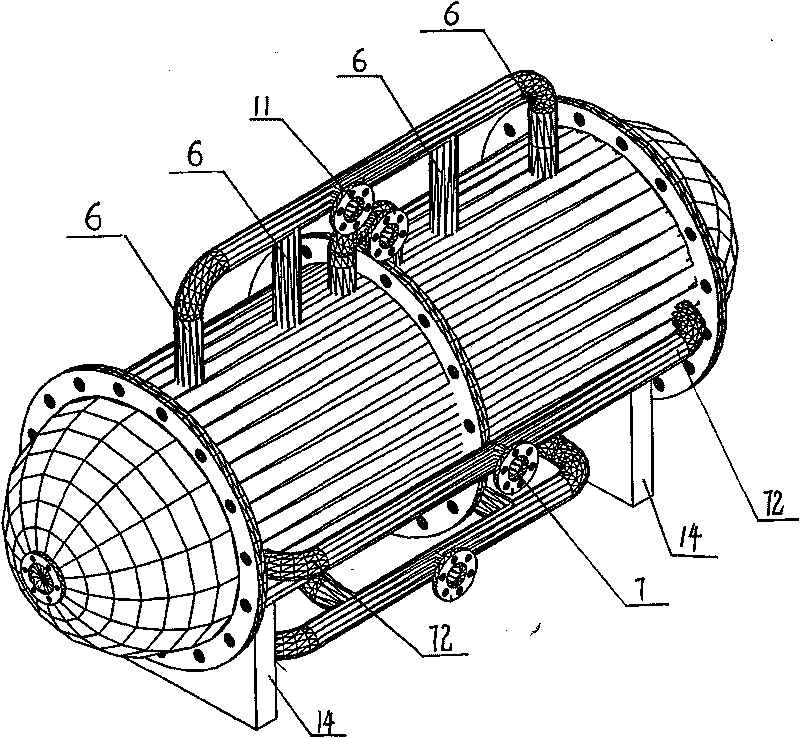

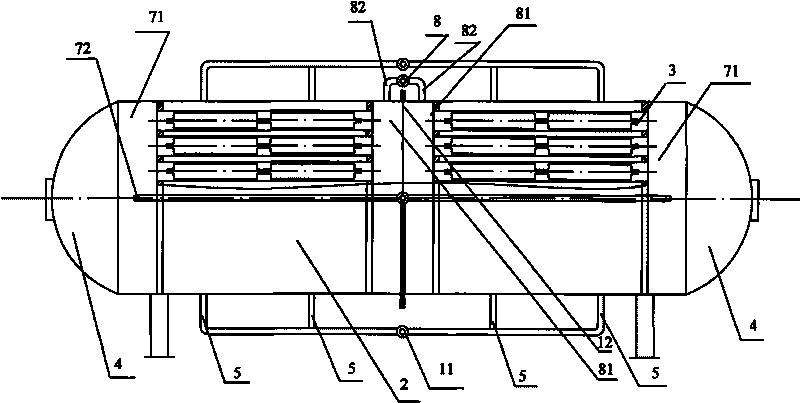

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] In order to solve the above-mentioned technical problems, the horizontal ozone generator of the present invention includes left and right ozone discharge chambers 1, 2, and one end of the left and right ozone discharge chambers 1, 2 is fixedly connected into one body through flanges, in order to increase the sealing , between the flange and the contact surfaces of the left and right ozone discharge chambers 1 and 2, there are silicone rubber sealing rings respectively; 1. The right ozone discharge chambers 1 and 2 respectively include a discharge chamber 3, and the two ends of the discharge chamber 3 are respectively provided with an air inlet part and an air outlet part, and the left and right ozone discharge chambers 1 and 2 are respectively connected with water inlet pipes 5, water outlet pipe 6, in order to avoid "dead angle" when the ozone discharge chamber is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com