Ultraviolet/titanium dioxide (UV/TiO2) reactor for disinfecting drinking water treated by activated carbon

A technology of titanium dioxide and activated carbon, applied in the direction of light water/sewage treatment, etc., can solve the problem of no application report in the design, and achieve the effect of avoiding the generation of disinfection by-products, considerable economic benefits, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

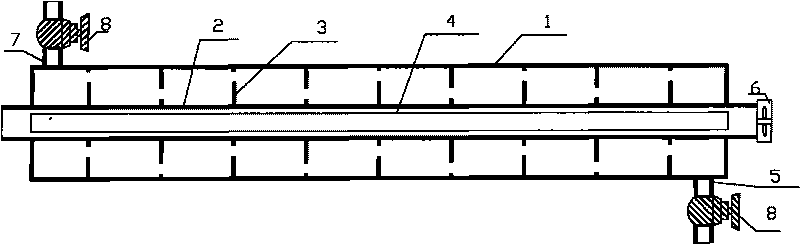

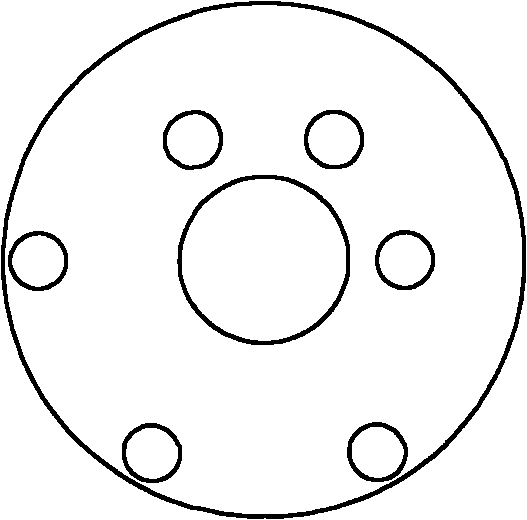

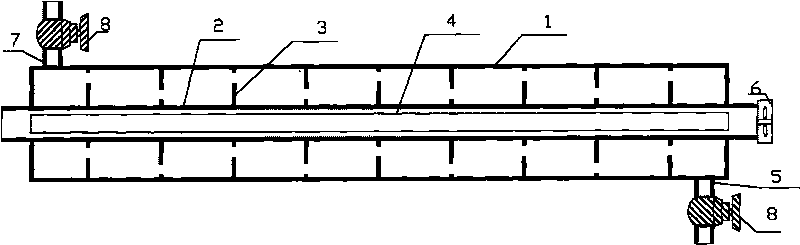

[0027] A drinking water activated carbon process effluent ultraviolet titanium dioxide disinfection reactor, which consists of an outer casing 1, an inner casing 2, and TiO 2 The ring plate 3, the ultraviolet lamp 4, the water outlet pipe 5 and the water inlet pipe 7 are composed. The outer casing 1 is provided with an inner casing 2, and the two ends of the outer casing 1 and the outer wall of the inner casing 2 are sealed and fixed with a plexiglass plate and glass glue. , the gap between the outer casing 1 and the inner casing 2 is arranged longitudinally with 6 pieces of TiO 2 Ring plate 3, the distance between two adjacent TiO2 ring plates 3 is 2×TiO 2 Inner diameter of annular plate 3, TiO 2 The contact parts between the annular plate 3, the inner sleeve 2 and the outer sleeve 1 are sealed with glass glue. The ultraviolet lamp 4 is located in the inner casing 2, making full use of the irradiation range of ultraviolet rays, preventing ultraviolet rays from leaking out, ...

Embodiment 2

[0035] A drinking water activated carbon process effluent ultraviolet titanium dioxide disinfection reactor, which consists of an outer casing 1, an inner casing 2, and TiO 2The ring plate 3, the ultraviolet lamp 4, the water outlet pipe 5 and the water inlet pipe 7 are composed. The outer casing 1 is provided with an inner casing 2, and the two ends of the outer casing 1 and the outer wall of the inner casing 2 are sealed and fixed with a plexiglass plate and glass glue. , the gap between the outer casing 1 and the inner casing 2 is arranged longitudinally with 9 pieces of TiO 2 Annular plate 3, two adjacent TiO 2 Ring plate 3 spacing is 2.2×TiO 2 Inner diameter of annular plate 3, TiO 2 The contact parts between the annular plate 3, the inner sleeve 2 and the outer sleeve 1 are sealed with glass glue. The ultraviolet lamp 4 is located in the inner casing 2, making full use of the irradiation range of ultraviolet rays, preventing ultraviolet rays from leaking out, and conv...

Embodiment 3

[0043] A drinking water activated carbon process effluent ultraviolet titanium dioxide disinfection reactor, which consists of an outer casing 1, an inner casing 2, and TiO 2 The ring plate 3, the ultraviolet lamp 4, the water outlet pipe 5 and the water inlet pipe 7 are composed. The outer casing 1 is provided with an inner casing 2, and the two ends of the outer casing 1 and the outer wall of the inner casing 2 are sealed and fixed with a plexiglass plate and glass glue. , the gap between the outer casing 1 and the inner casing 2 is arranged longitudinally with 12 pieces of TiO 2 Annular plate 3, two adjacent TiO 2 Ring plate 3 spacing is 2.5×TiO 2 Inner diameter of annular plate 3, TiO 2 The contact parts between the annular plate 3, the inner sleeve 2 and the outer sleeve 1 are sealed with glass glue. The ultraviolet lamp 4 is located in the inner casing 2, making full use of the irradiation range of ultraviolet rays, preventing ultraviolet rays from leaking out, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com