Road engineering base course and soil road base polymer grouting material

A technology for road engineering and grouting materials, applied in the field of roadbed and base reinforcement, can solve problems such as immaturity, and achieve the effects of high fluidity, good injectability and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

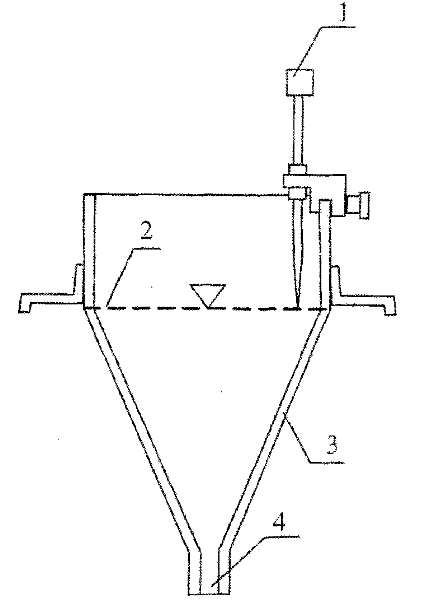

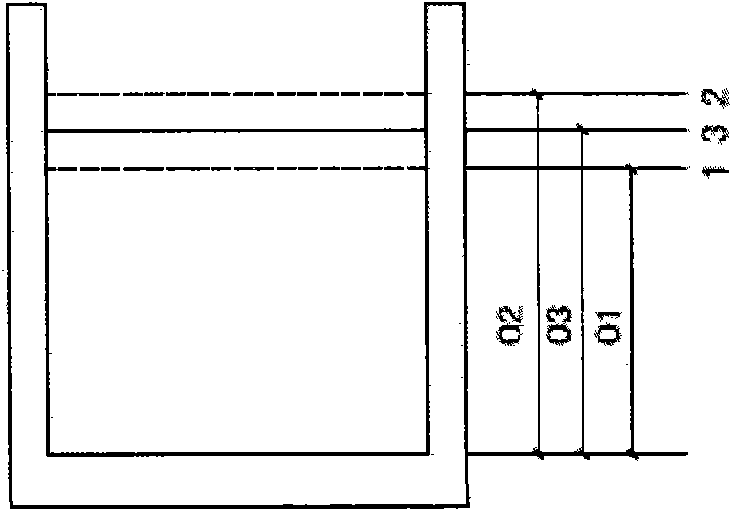

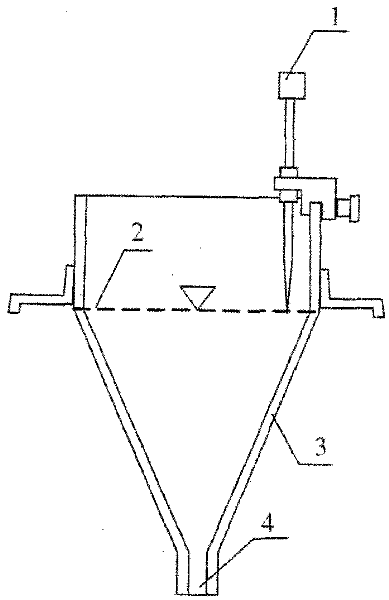

Image

Examples

Embodiment 1

[0020] A polymer grouting material for road engineering base and soil subgrade consists of 100 parts by weight of metallurgical slag, 30 parts by weight of high-calcium fly ash, 10 parts by weight of metakaolin, 1-3 parts by weight of thickening and water-retaining agent, and 30 parts by weight of alkali activator part and 4 parts by weight of admixture.

Embodiment 2

[0022] A polymer grouting material for road engineering base and soil subgrade consists of 100 parts by weight of metallurgical slag, 30 parts by weight of high-calcium fly ash, 10 parts by weight of metakaolin, 1-3 parts by weight of thickening and water-retaining agent, and 30 parts by weight of alkali activator part and 4 parts by weight of admixture.

Embodiment 3

[0024] A polymer grouting material for road engineering base and soil subgrade consists of 100 parts by weight of metallurgical slag, 30 parts by weight of high-calcium fly ash, 10 parts by weight of metakaolin, 1-3 parts by weight of thickening and water-retaining agent, and 30 parts by weight of alkali activator part and 3 parts by weight of admixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com