A method of solidifying heavy metal sludge using steel slag

A technology for heavy metal sludge and steel slag, applied in dehydration/drying/thickened sludge treatment, solid waste management, sustainable waste treatment, etc., can solve problems such as solidification of heavy metal sludge, reduce consumption, reduce production costs, and realize The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The method for utilizing steel slag to solidify heavy metal sludge, its specific steps are as follows:

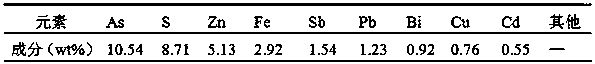

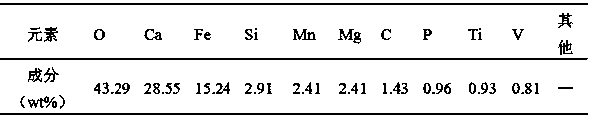

[0015] (1) Steel slag pretreatment: first crush 500g steel slag (steel slag is hot stewed steel slag, the steel slag composition table is shown in Table 1) and then screen to get particles ≤ 2mm, add water 0.12 times the particle mass, mix evenly, and seal in a constant temperature In the wet curing box, it is cured at a constant temperature of 70°C for 3 hours and then cooled to room temperature;

[0016] (2) Solidification method: first, mix steel slag, heavy metal sludge (heavy metal sludge composition is shown in Table 2), and cement according to the following mass percentages: 10% steel slag, 70% heavy metal sludge, and 20% cement to obtain a dry basis , then add 8% water on a dry basis and stir to obtain a solidified block (cylindrical body with a diameter of 50mm and a height of 50mm) by vibration pressing and molding, and the solidified block is cured in a na...

Embodiment 2

[0023] The method for utilizing steel slag to solidify heavy metal sludge, its specific steps are as follows:

[0024] (1) Steel slag pretreatment: first crush 500g steel slag (steel slag is hot stewed steel slag, the steel slag composition table is shown in Table 1) and then screen to get particles ≤ 2mm, add water 0.12 times the particle mass, mix evenly, and seal in a constant temperature In the wet curing box, it is cured at a constant temperature of 70°C for 3 hours and then cooled to room temperature;

[0025] (2) Solidification method: first, mix steel slag, heavy metal sludge (heavy metal sludge composition is shown in Table 2), and cement according to the following mass percentages: 40% steel slag, 50% heavy metal sludge, and 10% cement to obtain a dry basis , then add 8% water on a dry basis and stir to obtain a solidified block (cylindrical body with a diameter of 50mm and a height of 50mm) by vibration pressing and molding, and the solidified block is cured in a na...

Embodiment 3

[0028] The method for utilizing steel slag to solidify heavy metal sludge, its specific steps are as follows:

[0029] (1) Steel slag pretreatment: first crush 500g steel slag (steel slag is hot stewed steel slag, the steel slag composition table is shown in Table 1) and then screen to get particles ≤ 2mm, add water 0.12 times the particle mass, mix evenly, and seal in a constant temperature In the wet curing box, it is cured at a constant temperature of 70°C for 3 hours and then cooled to room temperature;

[0030] (2) Solidification method: first, mix steel slag, heavy metal sludge (heavy metal sludge composition is shown in Table 2), and cement according to the following mass percentages: 85% steel slag, 10% heavy metal sludge, and 5% cement to obtain a dry basis , then add 8% water on a dry basis and stir to obtain a solidified block (cylindrical body with a diameter of 50mm and a height of 50mm) by vibration pressing and molding, and the solidified block is cured in a nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com