A control method for realizing reduction and upgrading of steel slag, water-quenched slag and its application

A control method and technology of water quenching slag, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high energy consumption, long reaction period, and difficulty in ensuring the adequacy of the reaction, and achieve high efficiency The effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The implementation process of the embodiment includes:

[0040] Separately crush and grind steel slag, siliceous reducing agent and auxiliary agent until the Blaine specific surface area is 150-180m 2 / kg, add silicon powder with 8% steel slag quality as siliceous reducing agent, 1% bituminous coal as auxiliary agent, add appropriate amount of water and mix evenly, press into a cylindrical block with a diameter of 10cm and a height of 10cm, and dry it. Place the dried material in a high-purity MgO ceramic crucible, place the crucible in a vacuum high-temperature furnace for calcination, and control the calcination temperature system, respectively at 1050°C±50°C, 1200°C±50°C, 1300°C±50°C ℃ and 1525℃±25℃ for 30 minutes each in four stages. After the material is melted in the fourth heat preservation stage, the modifier calcium oxide is added to adjust the basicity R to be 1.0 (R=CaO / SiO 2 mass ratio).

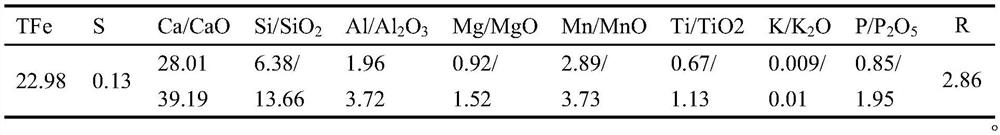

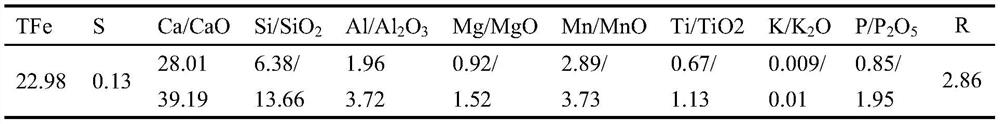

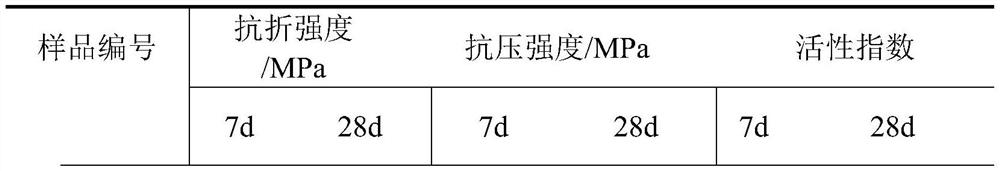

[0041]The reduced material was water-quenched to obtain reduced fe...

Embodiment 2

[0043] The implementation process of the embodiment includes:

[0044] Crush and grind the steel slag, siliceous reducing agent and auxiliary agent separately until the Blaine specific surface area is 200-230m 2 / kg, add silicon carbide with 15% steel slag mass as silicon reducing agent, 1.5% semi-coke as auxiliary agent, add appropriate amount of water and mix evenly, press into a cylindrical block with a diameter of 10cm and a height of 10cm, and dry . Place the dried material in a molybdenum crucible, place the crucible in a vacuum high-temperature furnace for calcination, and control the calcination temperature system, respectively at 1050°C±50°C, 1200°C±50°C, 1300°C±50°C and 1525°C ℃ ± 25 ℃ four stages of insulation for 30min each. After the material is melted in the fourth heat preservation stage, the modifying agent calcium oxide is added to adjust the basicity R to 1.1.

[0045] The reduced material was water-quenched to obtain reduced ferrosilicon alloy and water-q...

Embodiment 3

[0047] The implementation process of the embodiment includes:

[0048] Separately crush and grind steel slag, siliceous reducing agent and auxiliary agent until the Blaine specific surface area is 250-280m 2 / kg, add ferrosilicon with steel slag mass 30% as siliceous reducing agent, 2% mixture of bituminous coal and semi-coke (mass percentage of bituminous coal and semi-coke is 1:1) as auxiliary agent, add appropriate amount of water to mix evenly, and press into A cylindrical block with a diameter of 10 cm and a height of 10 cm is dried. Place the dried material in a high-purity MgO ceramic crucible, place the crucible in a vacuum high-temperature furnace for calcination, and control the calcination temperature system, respectively at 1050°C±50°C, 1200°C±50°C, 1300°C±50°C ℃ and 1525℃±25℃ for 30 minutes each in four stages. After the material is melted in the fourth heat preservation stage, the modifying agent silicon dioxide is added to adjust the basicity to 1.25.

[0049...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com