Smoke-free micro-expansive anhydrous stemming

A technology of anhydrous taphole and micro-expansion, applied in the field of smokeless micro-expansion anhydrous tappet, which can solve problems such as shedding and damage of taphole, broken iron mouth, and easy penetration of slag and iron liquid, so as to improve high-temperature performance and stimulate The effect of low odor and high curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

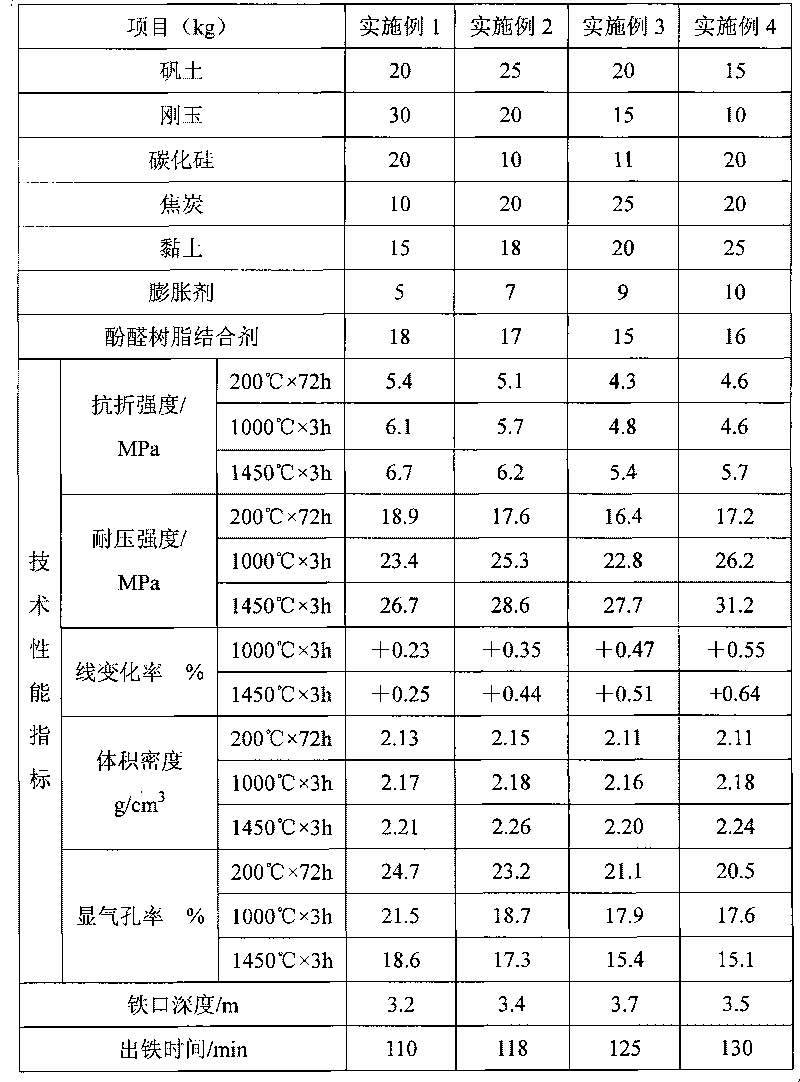

[0019] The present invention will be further described below in conjunction with specific examples, and the following examples are only used to illustrate the present invention rather than limit the present invention.

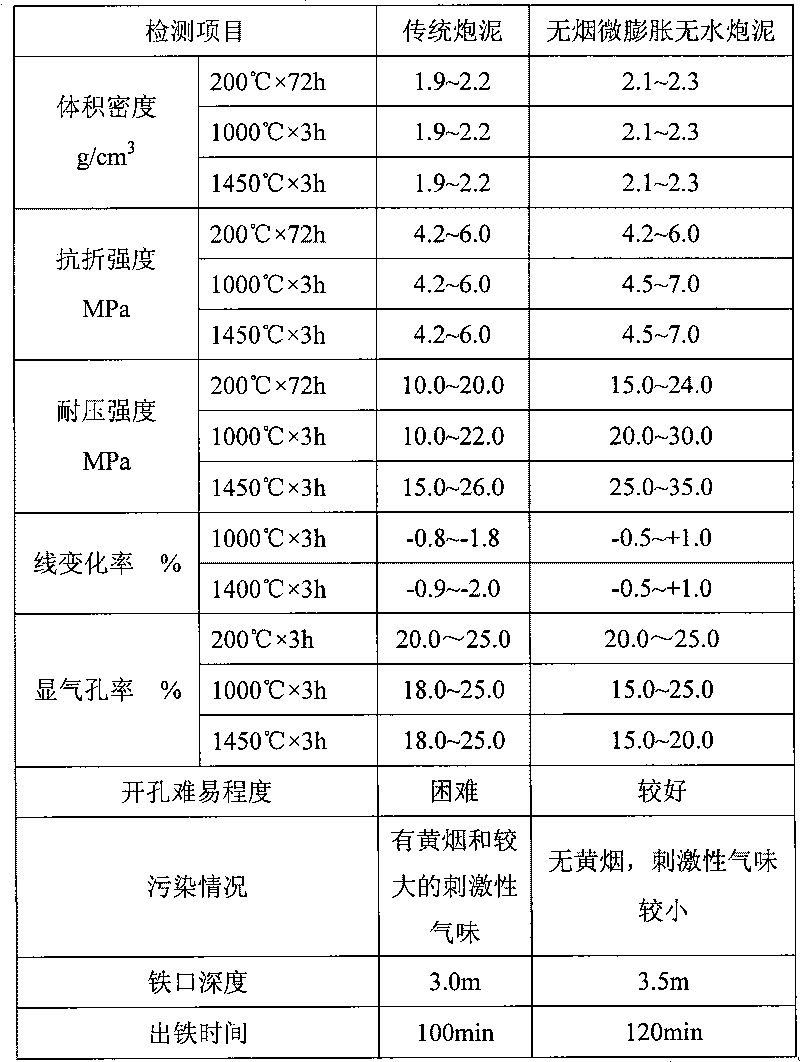

[0020] Table 2 lists the raw materials, content measured in parts by mass, and main technical performance indicators of the smokeless micro-expanded waterless taphole clay of the present invention.

[0021] Table 2 each embodiment and performance

[0022]

[0023] The manufacture method of each embodiment is identical, and its method is as follows:

[0024] 1. First, weigh various refractory raw materials such as bauxite, corundum, clay, silicon carbide, coke, expansion agent, etc. according to the measurement ratio of parts by mass in Table 2, mix them evenly and put them in bags for later use.

[0025] 2. Pour the mixed raw materials into the test wet mill, add an appropriate amount of phenolic resin binder and mix for about 30 minutes. After the binder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com