Liquid crystal orientation agent, liquid crystal orientation membrane and liquid crystal display component

A technology of liquid crystal alignment agent and carbon number, which is applied in the direction of liquid crystal materials, optics, instruments, etc., can solve the problems of general products without suitable structure and inconvenience, and achieve the effect of good long-term reliability and high voltage retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

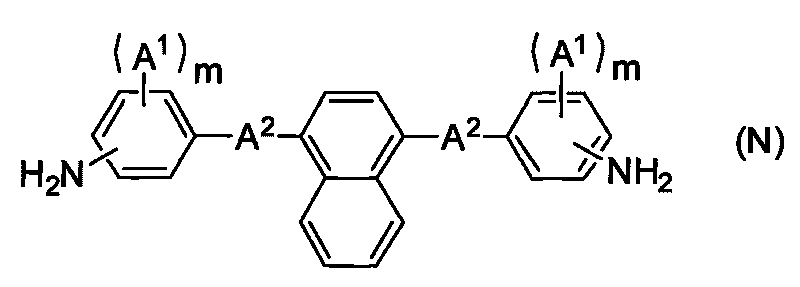

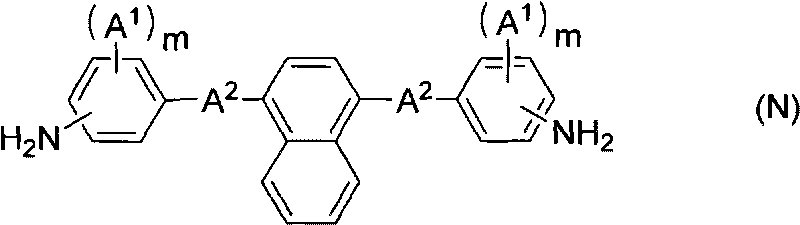

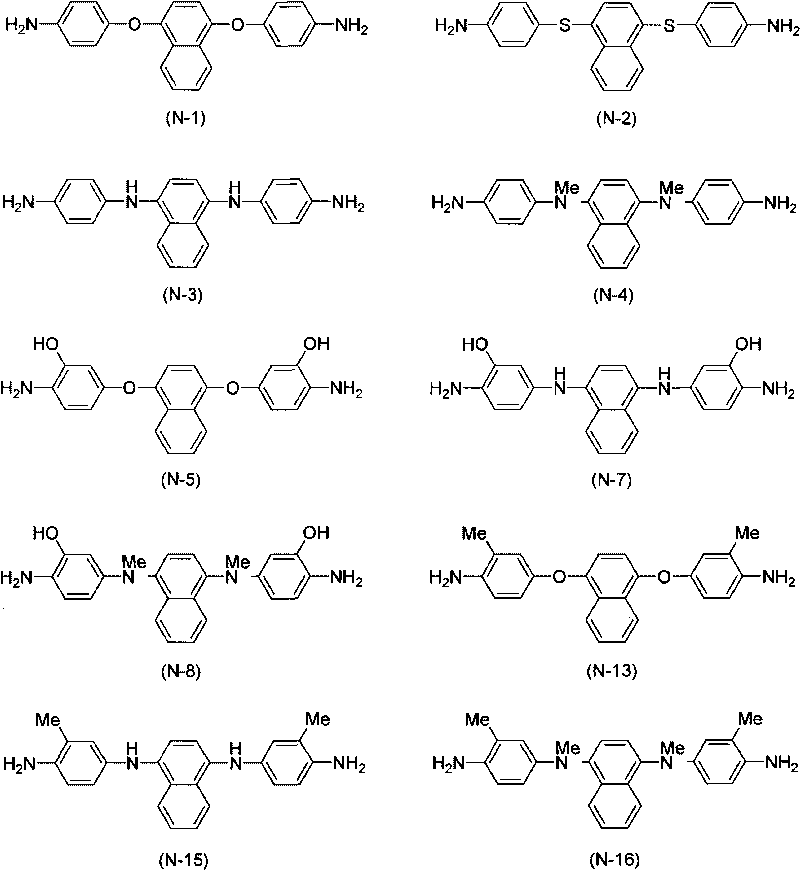

[0239] Hereinafter, the present invention will be explained through examples, but the present invention is not limited to these examples. The compounds used in the examples are as follows.

[0240]

[0241] Carboxylic acid (1): pyromellitic dianhydride (pyromellitic dianhydride)

[0242] Carboxylic acid (19): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0243]

[0244] Diamine (VI-7): 1,4-bis(4-aminophenyl)-1,4-diazepine

[0245] Diamine (V-1): 4,4'-Diaminodiphenylmethane

[0246] Diamine (V-7): 1,2-bis(4-aminophenyl)ethane

[0247] Diamine (XII-4-1): 1,1-bis[4-(4-aminophenoxy)phenyl-4-(trans-4-n-pentylcyclohexyl)cyclohexane

[0248] Diamine (XII-2-1): 1,1-bis[4-(4-aminophenylmethyl)phenyl]-4-n-heptylcyclohexane

[0249] Diamine (N-1): 1,4-bis(4-aminophenoxy)naphthalene

[0250] Diamine (V-36): N,N'-bis(4-aminophenyl)-N,N'-dimethylethylenediamine

[0251]

[0252] NMP: N-methyl-2-pyrrolidone

[0253] BC: Butyl cellosolve (ethylene glycol monobutyl ether)

[0254]

Synthetic example 1

[0256] Into a 100 mL four-necked flask equipped with a thermometer, a stirrer, a raw material input addition port, and a nitrogen introduction port, 2.242 g of diamine (VI-7), 1.072 g of diamine (N-1), and 0.569 g of diamine ( XII-2-1) and 80.0 g of dehydrated NMP were stirred and dissolved under a stream of dry nitrogen. Next, 0.683 g of carboxylic acid (1) and 1.434 g of carboxylic acid (19) were added, and they were reacted for 30 hours in a room temperature environment. When the reaction temperature rises during the reaction, the reaction temperature is suppressed to 70°C or less and allowed to react. Then, 14.0 g of BC was added to the obtained solution to obtain a polyamic acid solution having a concentration of 6% by weight. Let this polyamic acid be PA1. The weight average molecular weight of PA1 is 40,100.

[0257] The weight average molecular weight of the polyamic acid is obtained by the following method: the obtained polyamic acid is diluted with a phosphoric acid-...

Synthetic example 2~7

[0259] Except for changing the tetracarboxylic dianhydride and diamine as shown in Table 1, according to Synthesis Example 1, polyamic acid solutions (PA2) to (PA7) were prepared. Including Synthesis Example 1, the results are summarized in Table 1.

[0260]

[0261]

[0262]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com