Transfer device and vacuum processing apparatus using the same

A technology of conveying device and conveying room, which is applied in the direction of conveyor objects, transportation and packaging, program control manipulator, etc., to achieve the effect of heavy load and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

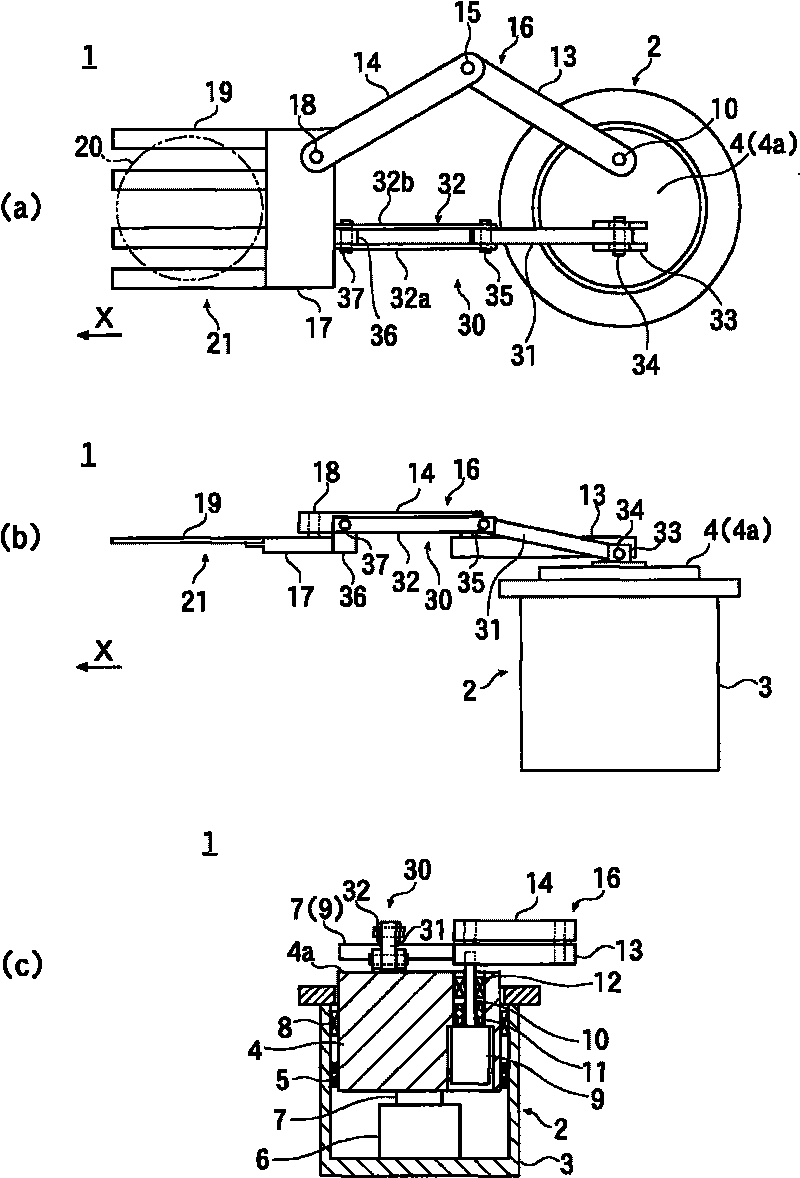

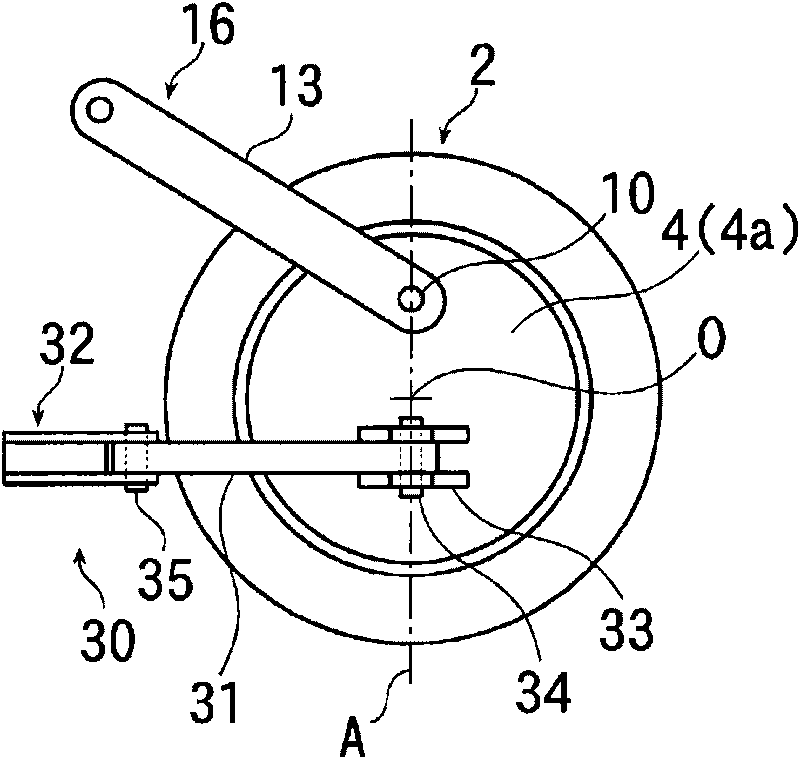

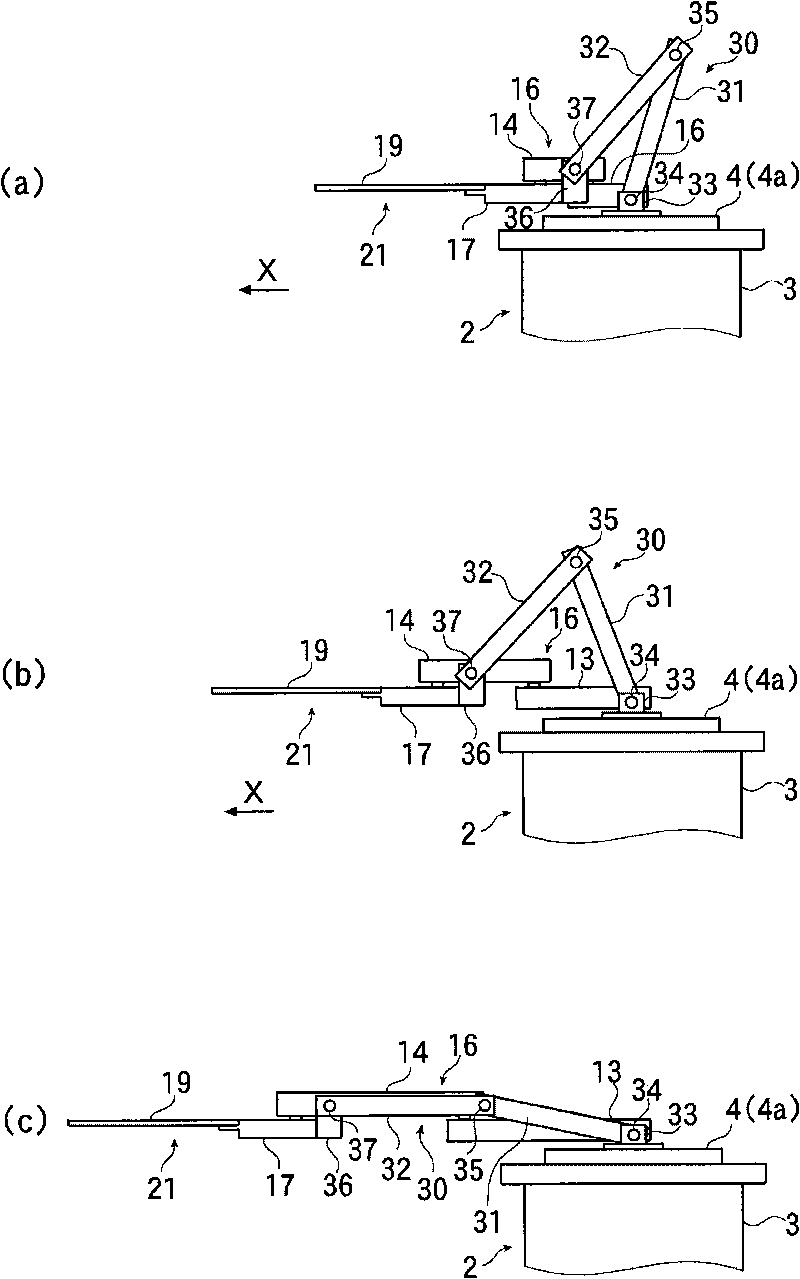

[0079] figure 1 (a)-(c) show the schematic structure of embodiment of the conveying apparatus of this invention, figure 1 (a) is a plan view, figure 1 (b) is a side view, figure 1 (c) is an internal configuration diagram. in addition, figure 2 It is an explanatory plan view showing the installation position of the guide mechanism in the conveying device.

[0080] like figure 1 As shown in (a) to (c), the conveying device 1 according to the present embodiment is configured to have a cylindrical casing 3 serving as the device main body 2 , and a turntable 4 is accommodated in the casing 3 .

[0081] The turntable 4 is formed in a cylindrical shape, and is rotatably attached to the inner wall of the casing 3 via a bearing 5 .

[0082] A drive motor 6 is arranged on the bottom surface of the cabinet 3 , and the front end of a rotary shaft 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com