Upward flow stationary bed filter unit and method for producing same

A filter device and fixed bed technology, which is applied in the field of upward flow fixed bed filter devices, can solve the problems of low operating flow rate, small sewage interception capacity, difficulty in large-scale equipment, etc., and achieve fast operating flow rate, large sewage interception capacity, and construction low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

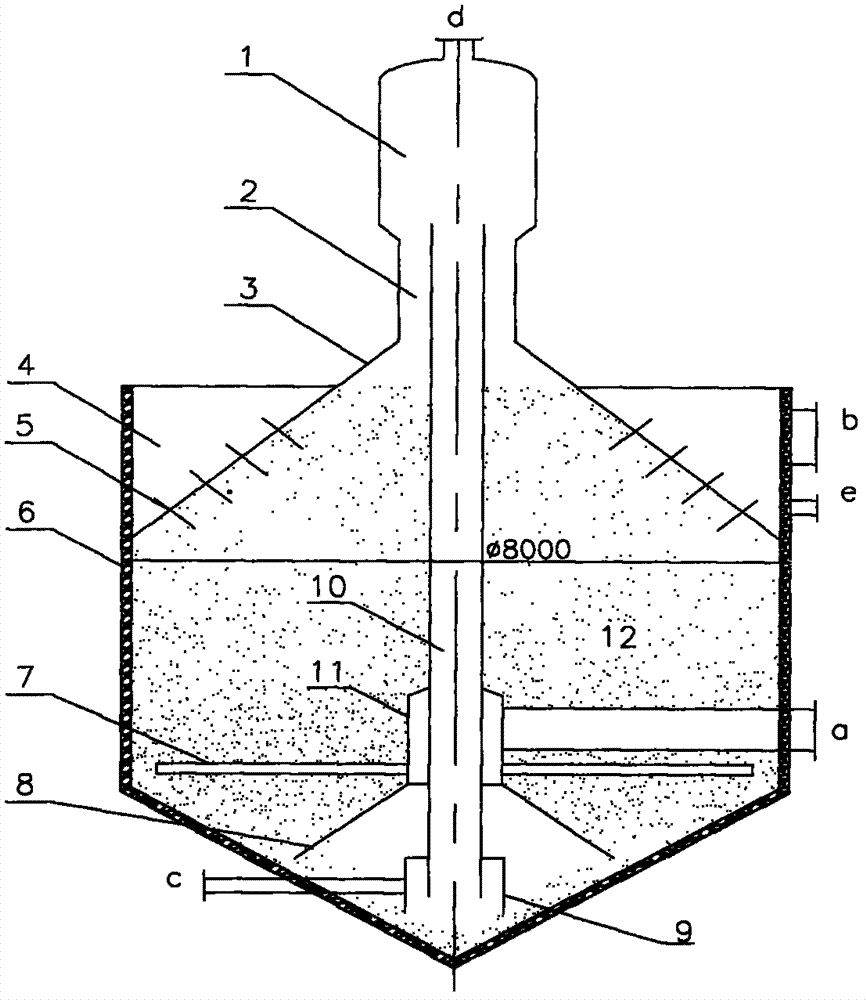

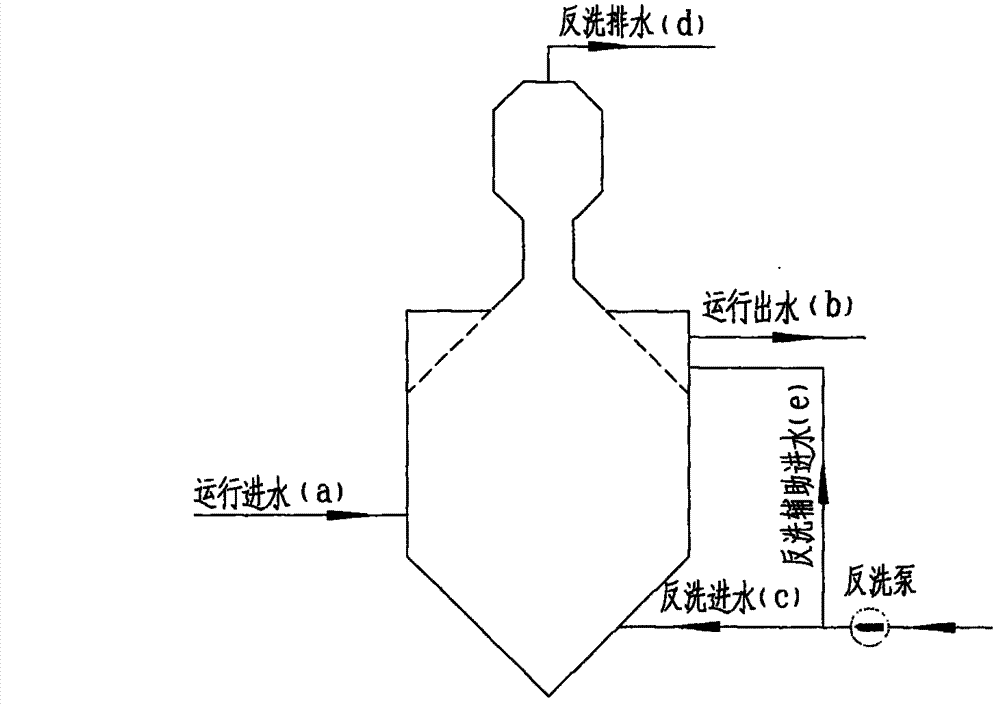

[0021] see figure 1 , the upflow fixed-bed filtering device that the present invention develops, and its composition is as follows:

[0022] The device is composed of separation chamber 1, filter material return channel 2, upper cone 3, running water outlet ring 4, water cap 5, straight section cylinder 6, water inlet distribution pipe 7, filter material deflector 8, backwash suction Sand nozzle 9, backwash sand conveying pipe 10, running water inlet distribution ring 11, filter material layer 12, characterized in that a filter chamber is set in the straight section cylinder 6, the upper and lower parts of the filter chamber are cones, and the cone angle 90°-120°, the upper cone 3 is provided with a running water outlet ring 4, the water cap 5 is set inside the running water outlet ring 4, and the lower part is provided with a running water inlet distribution ring 11, a water distribution pipe 7 and a filter deflector 8, In the center of the filter chamber, a backwash sand de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com