Method and equipment for coating dry-film lubricant

A dry film lubricant and coating technology, which is applied in coatings, devices for coating liquids on surfaces, pretreatment surfaces, etc., can solve problems such as uneven film thickness and flow marks on the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

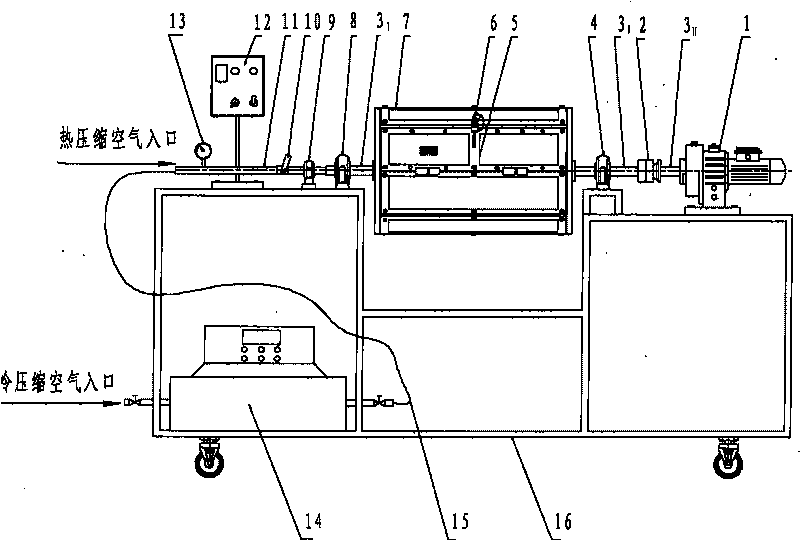

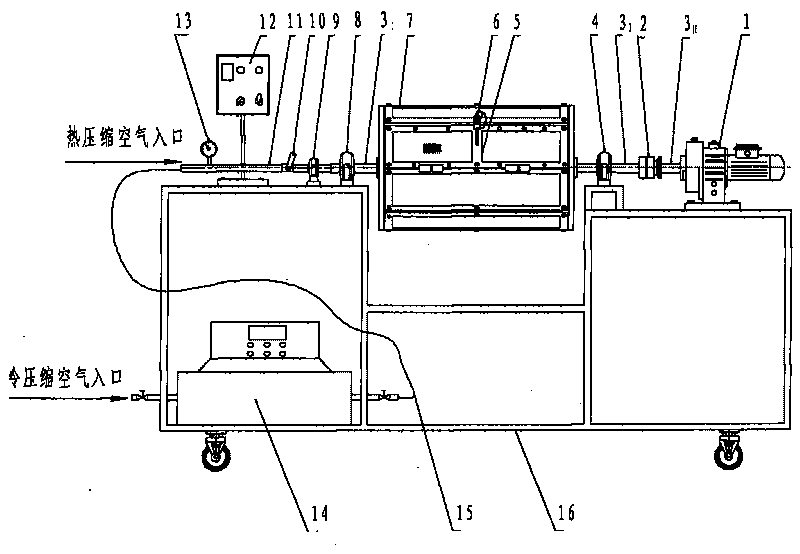

[0016] Taking the implementation process of a nut product coated with dry film lubricant as an example, the steps are as follows:

[0017] 1. Parts loading basket;

[0018] 2. Immerse in dry film lubricant and shake up and down for 10-15 seconds;

[0019] 3. Lift out the parts basket to filter out the remaining liquid;

[0020] 4. Pour the parts into the drum (7), close the drum door (5), and turn the latch (6) to lock the drum door (5);

[0021] 5. Turn on the power switch of the motor (1), adjust the frequency regulator (12) to make the motor (1) roll at 4 rpm;

[0022] 6. Simultaneously turn on the switch (10) to feed compressed air at 60°C, and adjust the pressure to 0.2Mpa;

[0023] 7. After rolling for 12 minutes, unscrew the door buckle (6), open the barrel door (5), pour the parts into the stainless steel grid tray and spread them evenly

[0024] 8. Transfer to an electric oven for pre-curing (150°C, 30 minutes);

[0025] 9. Cool to room temperature to measure coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com