Method for treating yeast wastewater

A treatment method, a technology for yeast wastewater, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large footprint, large investment, etc., and achieve treatment costs low cost, high biochemical efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

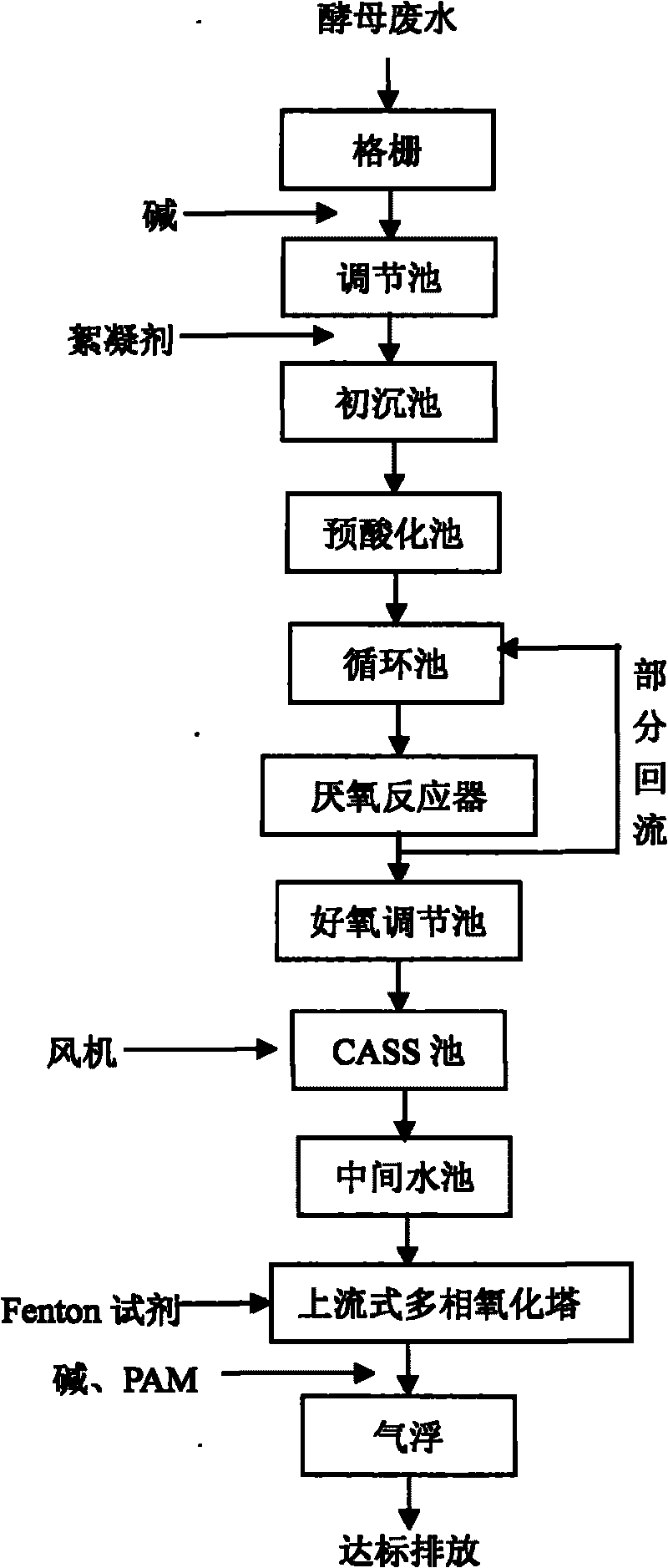

Image

Examples

Embodiment 1

[0045] A pilot test was carried out on wastewater from a yeast factory. The COD of the raw water was about 31600mg / L, and the surface load of the primary sedimentation tank was 0.85m 3 / m 2 h, the pre-acidification time is 8 hours, adjust the pH value of the wastewater to about 7 and pump it into the upflow multi-stage treatment anaerobic reactor, and the reactor load is 18.5kgCOD / m 3 d, the ascending flow rate is 6m / h, and the volume load of the aerobic tank is 1.0BOD / m 3 d, dissolved oxygen 2mg / L, sludge concentration about 3500mg / L, aerobic effluent COD 380mg / L, add H 2 o 2 800mg / L, FeSO 4 ·7H 2 O 436mg / L, the hydraulic retention time in the upflow heterogeneous oxidation tower is 0.5h, after the air flotation treatment, the COD of the effluent is 87mg / L, reaching the first-level national comprehensive wastewater discharge standard.

Embodiment 2

[0047] A certain yeast factory in Guangxi adopts the method of the present invention to treat the waste water of the factory, the COD of the waste water is about 27000mg / L, and the design treatment capacity is 3000m 3 / d, the surface load of the primary sedimentation tank is 0.97m 3 / m 2 h, the hydraulic retention time is 3 hours, the pre-acidification time is 10 hours, the pH value of the effluent from the circulating tank is about 7, and it is pumped into the upflow multi-stage treatment anaerobic reactor, and the reactor load is 20kgCOD / m 3 d, the ascending flow rate is 7.5m / h, and the volume load of the aerobic tank is 0.8BOD / m 3 d, dissolved oxygen 2mg / L, sludge concentration about 3500mg / L, aerobic effluent COD 300mg / L, add H 2 o 2 900mg / L, FeSO 4 ·7H 2 O 380mg / L, the hydraulic retention time in the upflow heterogeneous oxidation tower is 1h, after the air flotation treatment, the COD of the effluent is 92mg / L, which meets the national first-class standard for compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com