Method for stockpiling red mud generated in process of producing aluminum oxide by combination method

A technology of alumina and combined method, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of water occupying storage capacity, red mud recovery and high transportation costs, and achieve physical and mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the invention:

[0020] The sintering red mud and Bayer red mud produced in the combined alumina production are transported to the press filter workshop of the red mud yard by pipeline wet method. After dehydration by matching filter press, the filter cake is transported by belt, and then transferred to the tailings reservoir area by loaders and transport vehicles. The moisture content of the red mud after pressure filtration is 28-33%. The red mud attached liquid discharged during the filter press process is directly transported back to the alumina through the pipeline from the filter press workshop, without pumping it back from the tailings pond, which not only reduces the impact of water on the safety and environmental protection of the tailings pond, but also reduces energy consumption. , Equipment consumption.

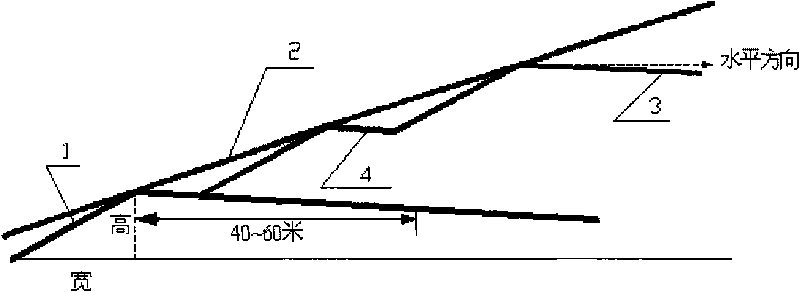

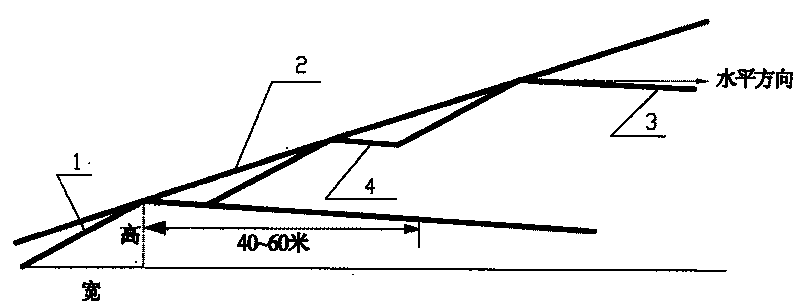

[0021] When the red mud is stockpiled, the height-to-width ratio of the single-stage side slope 1 outside the storage area is 1:2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com