Polyurethane elastic self-leveling mortar

A self-leveling mortar and polyurethane elastic technology, applied in the field of polyurethane elastic self-leveling mortar, can solve problems such as national economic losses, and achieve the effects of extending service life, high tensile resistance and reducing direct economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

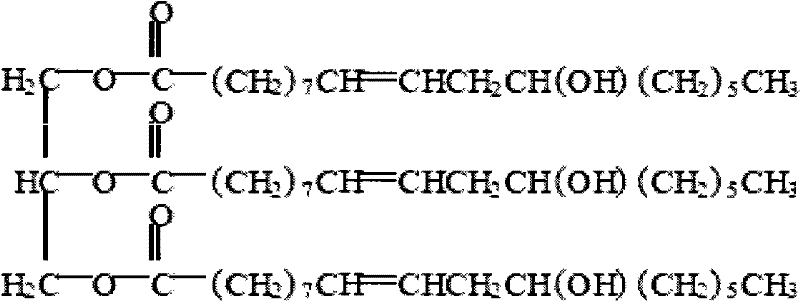

Method used

Image

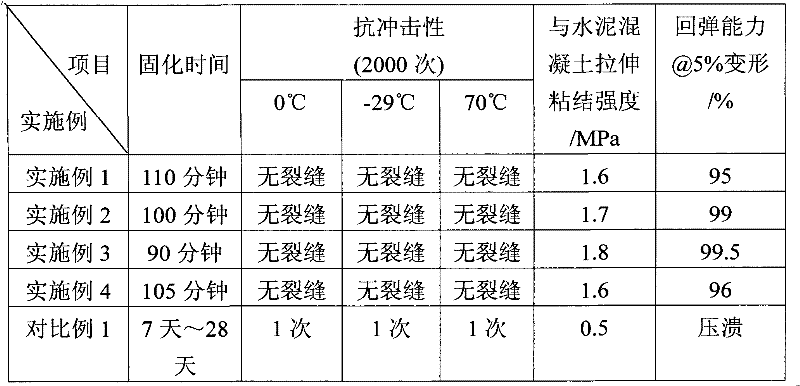

Examples

Embodiment 1

[0036] Preparation of component A:

[0037] Using a high-speed disperser, add 90 parts of polyisocyanate (modified MDI) in a sealable stainless steel reaction tank or reaction kettle under vacuum, air isolation or inert gas protection; 10 parts of water-absorbing agent and defoamer in total, Thoroughly mix and stir for about 15 to 30 minutes, preferably vacuum defoaming for 30 minutes to obtain component A, and then pack the product in a vacuum, in the absence of air or under the protection of an inert gas.

[0038] Preparation of component B:

[0039] Using a high-speed disperser, pour 30 parts of castor oil and 5 parts of toner into a stainless steel reaction tank or reaction kettle under vacuum, air isolation or inert gas protection, and then disperse at a speed of more than 1000 revolutions per minute. About 30 minutes to make the fineness less than 20 microns; then put 55 parts of castor oil and 10 parts of leveling agent, dehydrating agent, defoaming agent and catalyst ...

Embodiment 2

[0044] Preparation of component A:

[0045] Use a closed stainless steel reaction tank or reaction kettle, under vacuum, air isolation or inert gas protection, add 100 parts of polyisocyanate (modified MDI) in the airtight reaction tank or reaction kettle; then vacuum, isolation air or Under the protection of inert gas, the product can be packed.

[0046] Preparation of component B:

[0047]Using a high-speed disperser, pour 30 parts of castor oil and 5 parts of toner into a stainless steel reaction tank or reaction kettle under vacuum, air isolation or inert gas protection, and then disperse at a speed of more than 1000 revolutions per minute. About 30 minutes to make the fineness less than 20 microns; then put 55 parts of castor oil and 10 parts of leveling agent, dehydrating agent, defoaming agent and catalyst under vacuum, air isolation or inert gas protection, and mix and stir for 30 minutes Then it is best to degas under vacuum for 30 minutes to obtain component B, and...

Embodiment 3

[0052] Preparation of component A:

[0053] In a vacuum, isolated from air or under the protection of an inert gas, use a high-speed disperser to add 90 parts of polyisocyanate (modified MDI) into a sealable stainless steel reaction tank or reaction kettle; a total of 10 parts of water-absorbing agent and defoamer, Thoroughly mix and stir for about 15-30 minutes, preferably vacuum defoaming for 30 minutes to obtain component A, and then pack the product in a vacuum, air-isolated or protected by an inert gas.

[0054] Preparation of component B:

[0055] Under the conditions of vacuum, air isolation or inert gas protection, use a high-speed disperser, first pour 30 parts of castor oil and 3 parts of toner into a stainless steel reaction tank or reaction kettle, and then disperse at a speed of more than 1000 revolutions per minute. For about 30 minutes, make the fineness less than 20 microns; then put 60 parts of castor oil and 7 parts of leveling agent, dehydrating agent, defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com