High molecular slow-release boric fertilizer and preparation method thereof

A polymer, slow-release technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problem of no polymer slow-release boron fertilizer, etc., and achieve the effect of improving the effective utilization rate and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

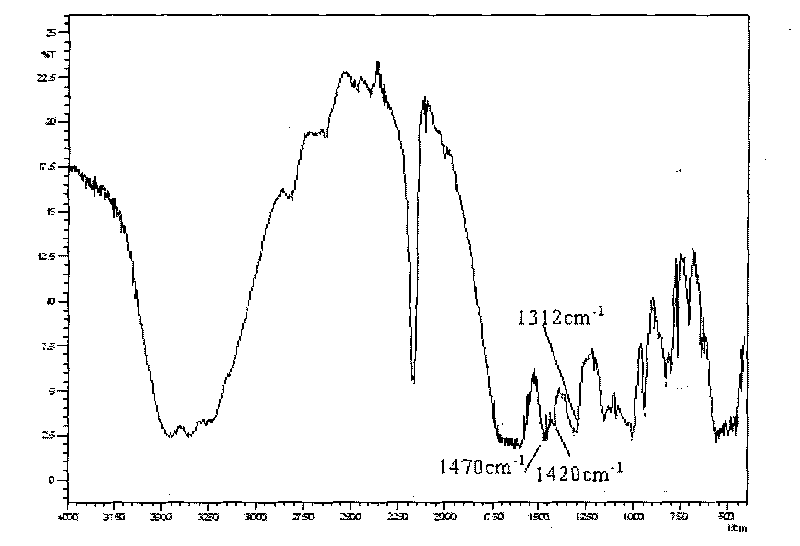

Embodiment 1

[0034] Polymer slow-release boron fertilizer is a compound with the following general formula:

[0035]

[0036] In the formula: m=1-10, n=0-5, x=5-10.

[0037] In this embodiment, m=1, n=0, x=5, the mass percentage of boron in the molecule is 5.3wt%, the mass percentage of nitrogen is 27.2wt%, and the potassium content is represented by K 2 The mass percentage of O is expressed, and K 2 The mass percent content of O is 22.8wt%. The molecular weight is 1000, and the total nutrient content is 55.3%.

[0038] For specific preparation, add 6.2kg of boric acid and 5.6kg of potassium hydroxide to a 40-liter stainless steel reactor, and heat to 80-100°C (80°C or 85°C or 90°C or 95°C or 100°C) to generate boric acid dihydrogen Potassium, then add 12kg of urea, control the reaction temperature to 110°C ~ 140°C (110°C or 120°C or 130°C or 140°C), keep the reactant in a molten state, then add 2.4kg of formaldehyde, continue to proceed under this condition Polycondensation reactio...

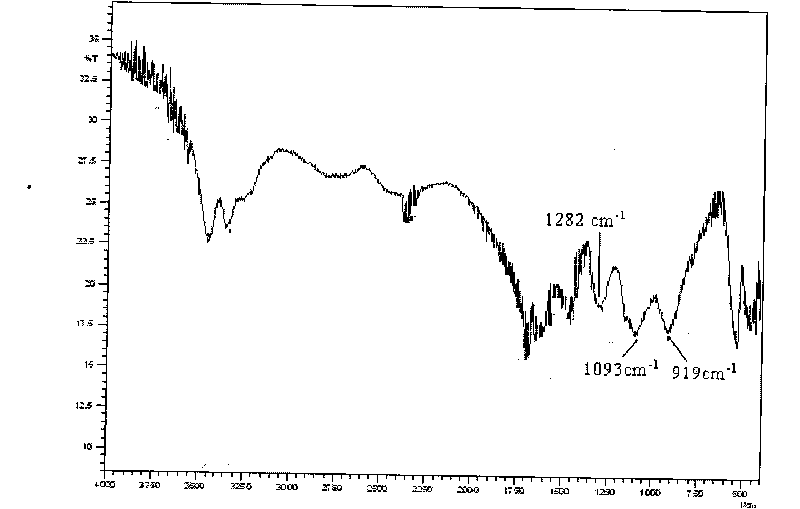

Embodiment 2

[0040] Polymer slow-release boron fertilizer is a compound with the following general formula:

[0041]

[0042] In the formula: m=1-10, n=0-5, x=5-10.

[0043] In this embodiment, when m=1, n=5, and x=10, the mass percentage of boron in the molecule is 1.1 wt%, the mass percentage of nitrogen is 22.7 wt%, and the potassium content is expressed in K 2 The mass percentage of O is expressed, and K 2 The mass percentage of O is 28.2wt%, and the phosphorus content is represented by P 2 o 5 The mass percentage content expressed, P 2 o 5 The mass percentage content of is 35.5wt%. The molecular weight is 10000, and the total nutrient content is 87.5%.

[0044] For specific preparation, add 0.93kg of boric acid and 1.04kg of potassium carbonate to a 40-liter stainless steel reactor, and heat to 80-100°C (80°C or 85°C or 90°C or 95°C or 100°C) to generate potassium dihydrogen borate , then add 10.2kg of potassium dihydrogen phosphate and 10.8kg of urea, control the reaction tem...

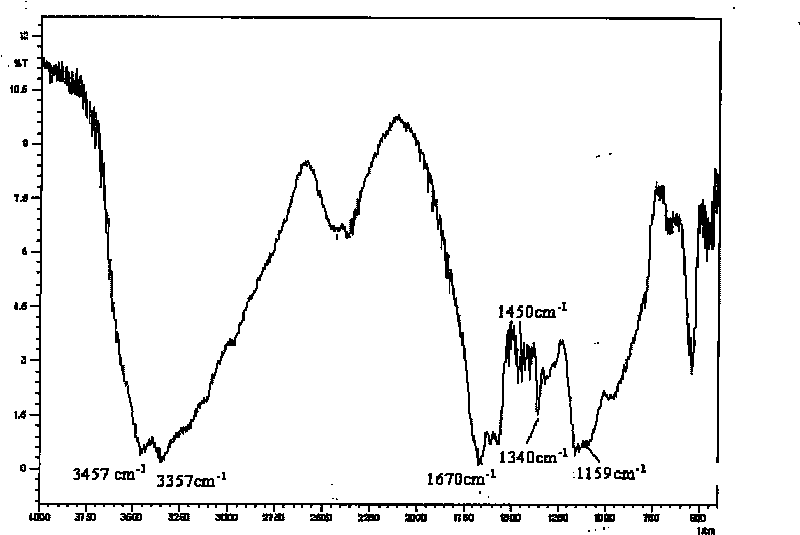

Embodiment 3

[0046] Polymer slow-release boron fertilizer is a compound with the following general formula:

[0047]

[0048] In the formula: m=1-10, n=0-5, x=5-10.

[0049] In this embodiment, m=10, n=0, x=10, the mass percentage of boron in the molecule is 8.3wt%, the mass percentage of nitrogen is 23.6wt%, and the potassium content is represented by K 2 The mass percentage of O is expressed, and K 2 The mass percent content of O is 35.7wt%, the molecular weight is 13160, and the total nutrient content is 67.6%.

[0050] For specific preparation, add 7.5kg of boric acid and 6.7kg of potassium hydroxide to a 40-liter stainless steel reactor, and heat it to 80-100°C (80°C or 85°C or 90°C or 95°C or 100°C) to generate boric acid dihydrogen Potassium, then add 8 kg of urea, control the reaction temperature to 110 ° C ~ 140 ° C (110 ° C or 120 ° C or 130 ° C or 140 ° C), keep the reactant in a molten state, then add 0.32 kg of formaldehyde, continue polycondensation under this condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com