Lightweight component in hybrid construction

一种轻质、部件的技术,应用在车辆部件、家用元件、上部结构等方向,能够解决增加重量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0195]The preparation process of component B3) is carried out under inert gas, for example under carbon dioxide, nitrogen or noble gases, of which argon is mentioned in particular. The process of the invention is carried out at a temperature of from 60°C to 200°C. It is preferred to operate at a temperature of from 130°C to 180°C, especially up to 150°C, or below. Particular preference is given to a maximum temperature of up to 145°C, very particular preference to a temperature of up to 135°C. The pressure conditions used in the preparation process are not critical. It is possible to operate at significantly lower pressures, for example from 10 mbar to 500 mbar. The method can also be carried out at pressures above 500 mbar. For reasons of simplicity, carrying out the reaction at atmospheric pressure is preferred; however, carrying out at slightly elevated pressure is also possible, for example up to 1200 mbar. It is also possible to operate at significantly elevated press...

example

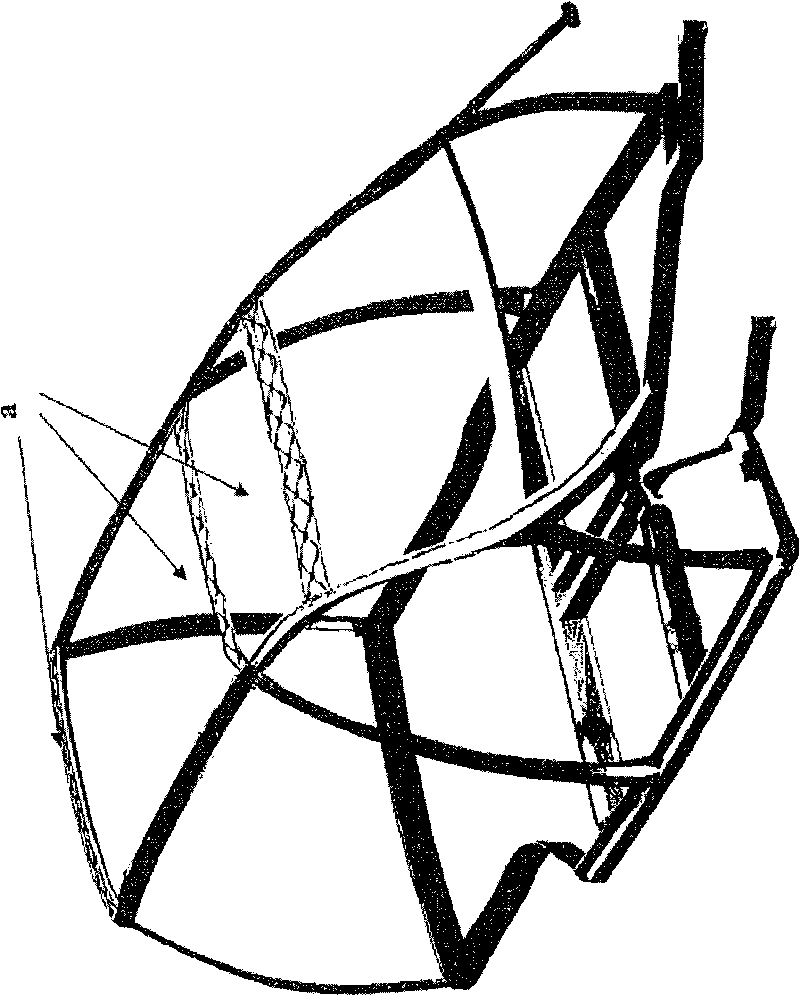

[0345] figure 1 A roof structure according to the invention is shown, where a is a sheet metal profile with a molded-on rib structure.

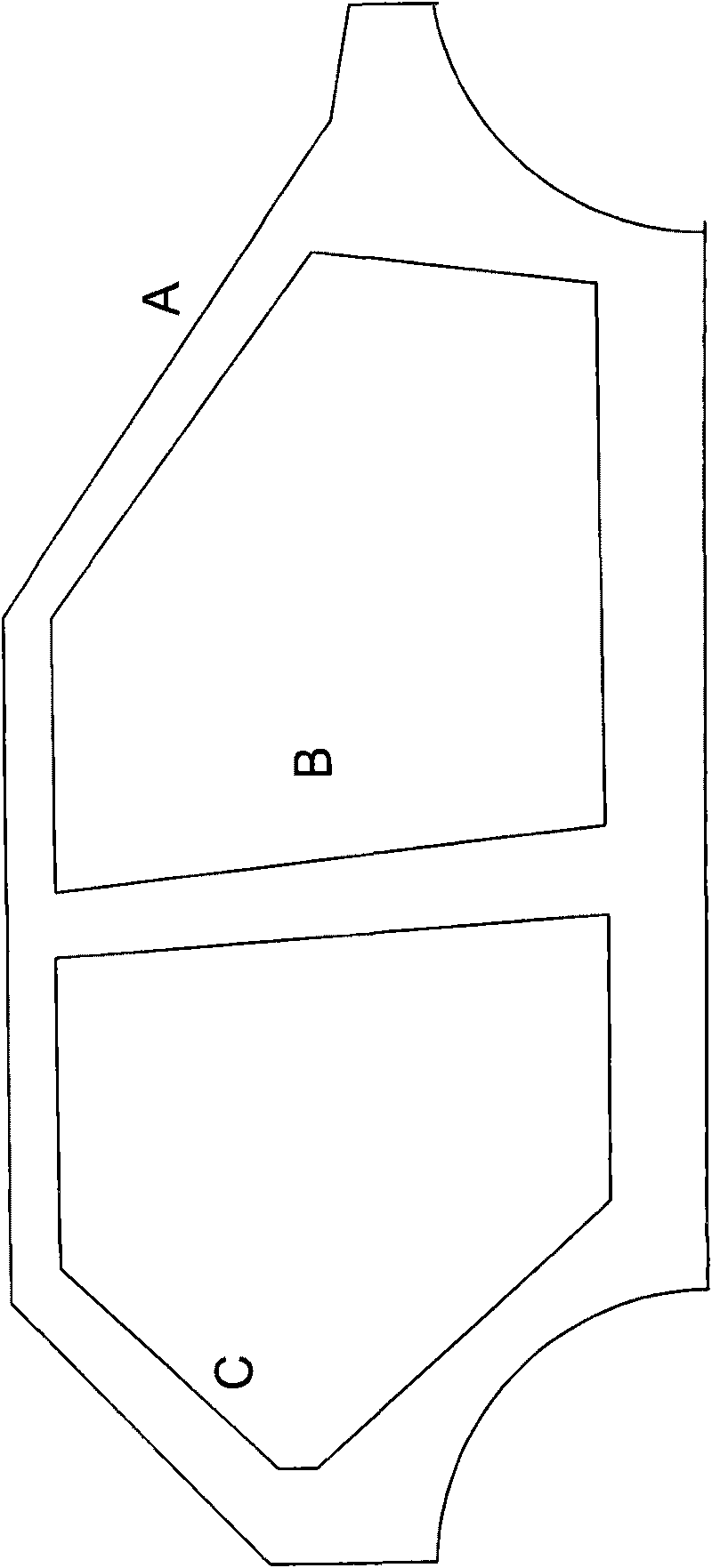

[0346] figure 2 One pillar structure for a vehicle according to the invention is shown, where A is the A-pillar, B is the B-pillar and C is the C-pillar.

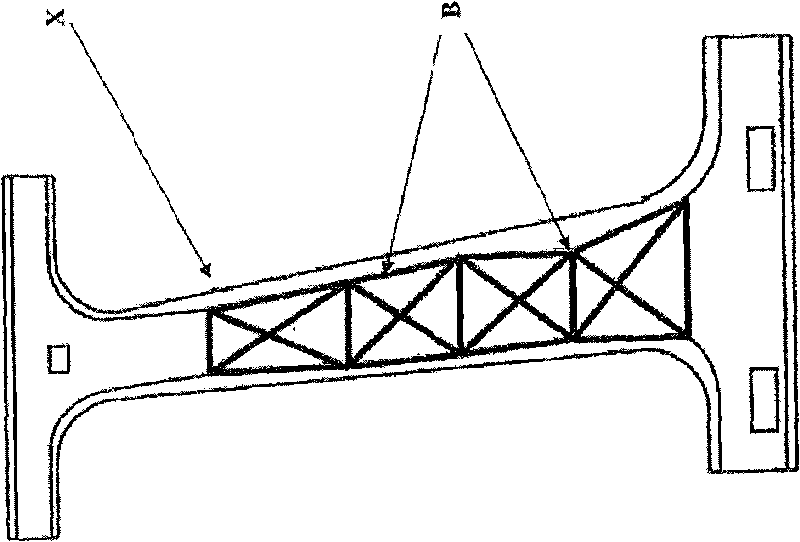

[0347] image 3 A B-pillar (B) according to the invention is shown, the inner sheet metal of which has been reinforced with molded-on plastic in a rib configuration. X indicates possible spot weld locations.

[0348] Figure 4 Shown is an automotive rocker structure for a motor vehicle having a Y longitudinal member at the front end and a Z longitudinal member at the rear end according to the invention. A means in Figure 5 part shown in.

[0349] Figure 5 Shown in section detail A-A form according to Figure 4 where i is the welded connection, j is the outer sheet metal of the car sill and k is the inner sheet metal of the car sill, 1 is the underbody sheet metal of the motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com