Process for lateral translation of coke dry quenching

A technology of coke CDQ and lateral movement, which is applied in the field of coke CDQ lateral movement, can solve the problems of increasing the operating cycle of the hoist, inability to directly traverse, long process time, etc., to achieve superior energy-saving effects, save operating time, save The effect of the de-calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

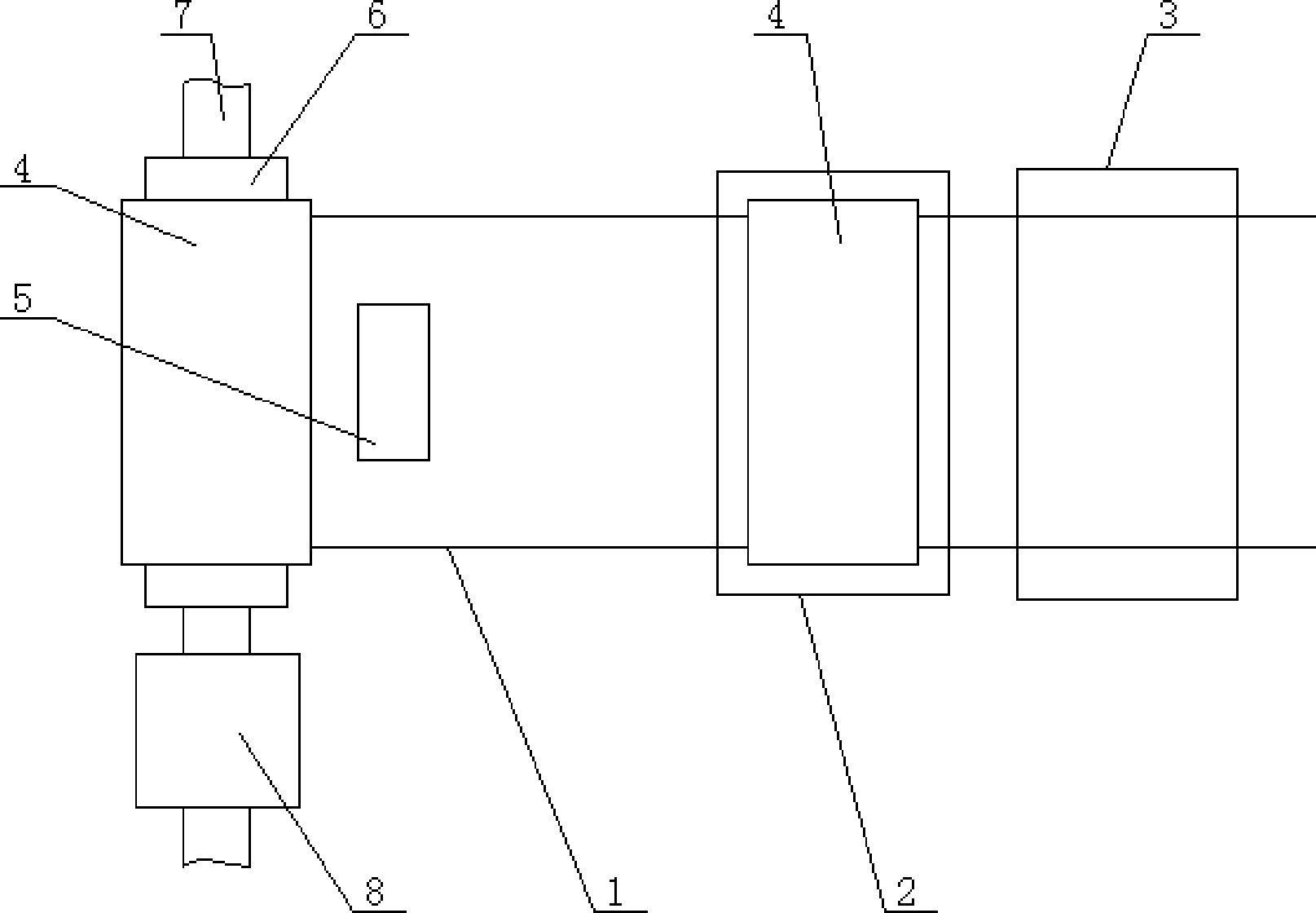

[0009] The coke CDQ traversing process steps described in the present invention are as follows: the coke CDQ traversing process comprises the following steps:

[0010] ① The electric locomotive 8 has a trolley 6, on which a wheeled coke tank 4 with red coke is loaded; the electric locomotive 8 drives the trolley 6 to move along the quenching car track 7 to the vicinity of the traverse track 1 And align the trolley 6 with the traversing track 1 through the positioning device;

[0011] ② The traction mechanism 5 of the traversing track 1 is connected with the above-mentioned coke tank 4 equipped with red coke wheels, and the coke tank 4 equipped with red coke wheels is pulled off from the trolley 6; The lower part is the lifting position, and the coke tank 4 of the traction mechanism 5 pulls the pulley to move along the traversing track 1 to the position in front of the lifting position for waiting;

[0012] ③The hoist in the hoist shaft 2 lowers another empty wheeled coke pot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com