Drilling bit for guiding horizontal roatatably-jetting construction and construction method thereof

A technology of horizontal rotary jetting and construction method, which is applied to drill bits, excavation, drilling equipment, etc., can solve the problems of difficult monitoring and guidance, low production efficiency and high production cost, and achieve the effects of low cost, high production efficiency and long transmission distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

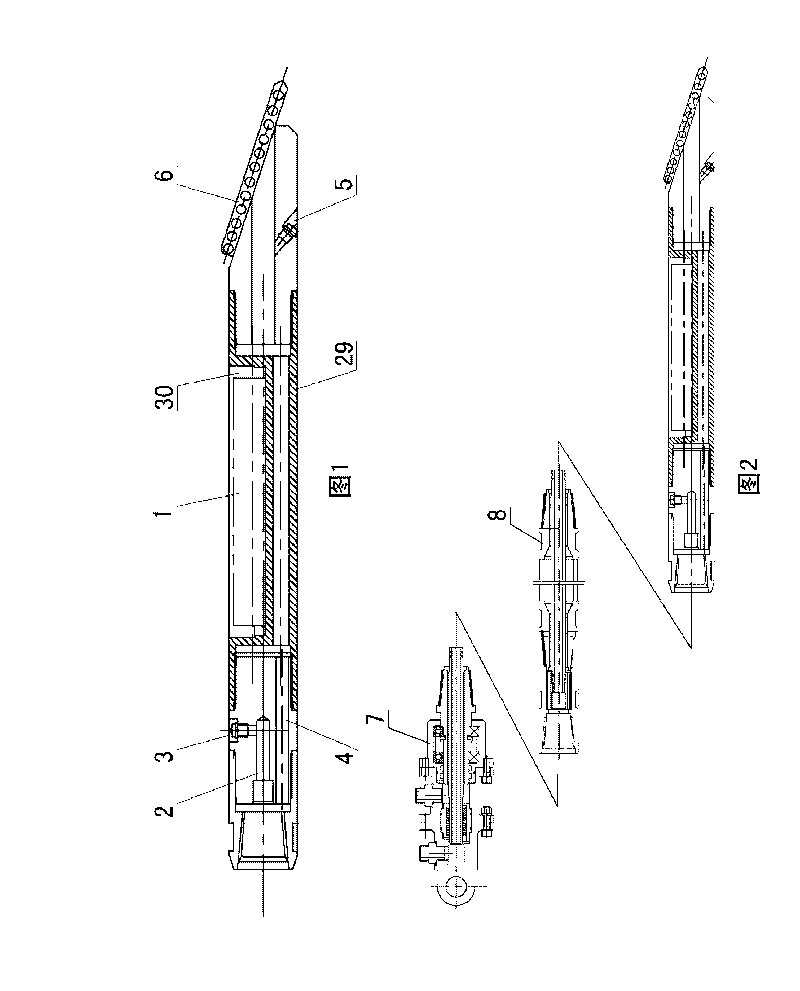

[0057] Examples see figure 1 , figure 2 As shown, the drill bit for guiding horizontal rotary spraying construction includes a drill body 29 and a wedge plate 6 fixedly connected to the head of the drill body. In the drill body, a high-pressure water channel 2 and a high-pressure slurry channel 4 are arranged axially. The high-pressure water channel 2 is provided with a water spray nozzle 3 laterally, the high-pressure slurry channel 4 is provided with a spray nozzle 5 laterally, and a groove 30 is provided on the side wall of the main body of the drill bit, and an inherent probe 1 is embedded in the groove, see Figure 8 , The outer surface of the probe 1 is covered with a rubber hose 28, and the rubber hose is tightly connected with the probe through a pipe collar 27. Such as figure 1 As shown, the drill adopts a concentric circle structure and consists of 6 parts. The wedge plate 6 is integrated with the drill bit by welding, and about Φ8-12mm water holes are opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com