Torque-withstanding drill pipe elevating device

An elevator and drill pipe technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of large well site occupation, low drill pipe efficiency, and large wellhead space, so as to reduce the operating space and improve the operation. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Taking a torsion-bearing drill pipe elevator device used in the lifting operation process of a drill pipe with an outer diameter of 127 mm as an example, the present invention will be further described in detail.

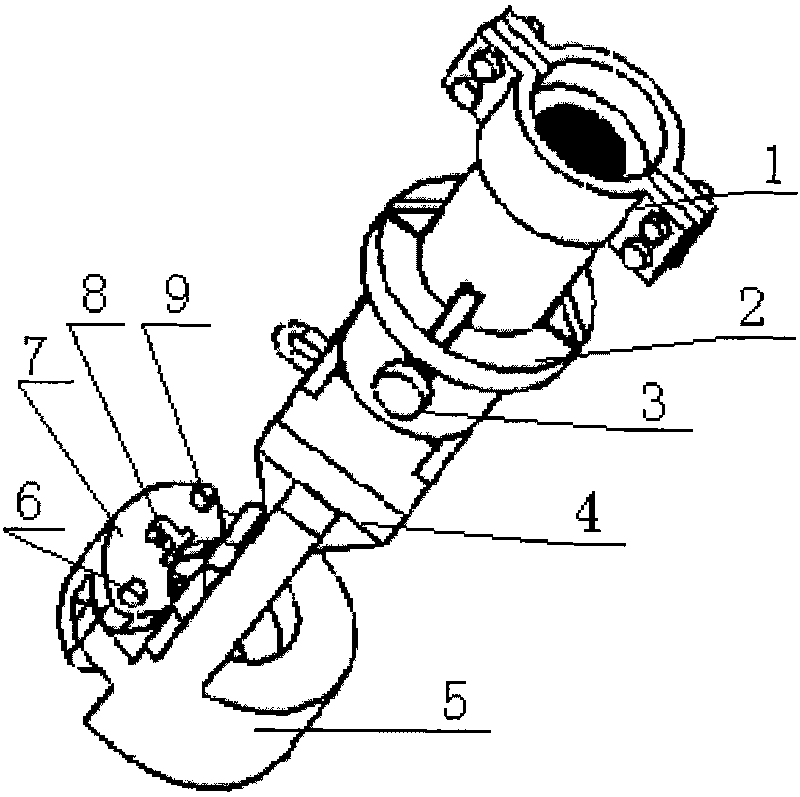

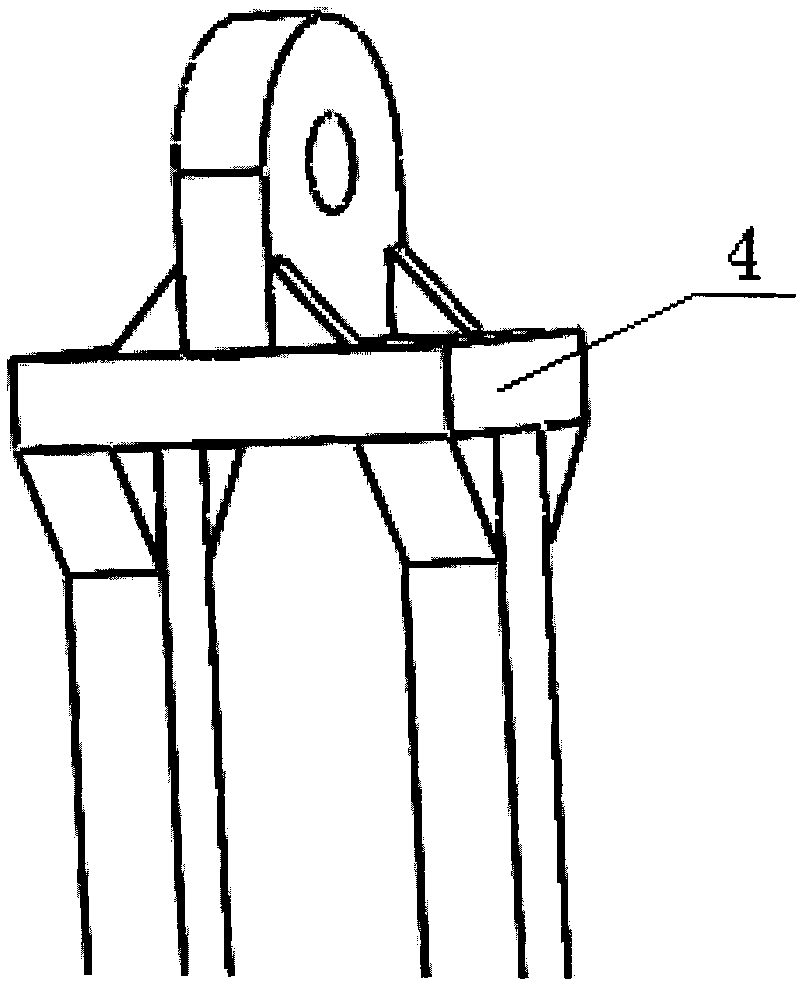

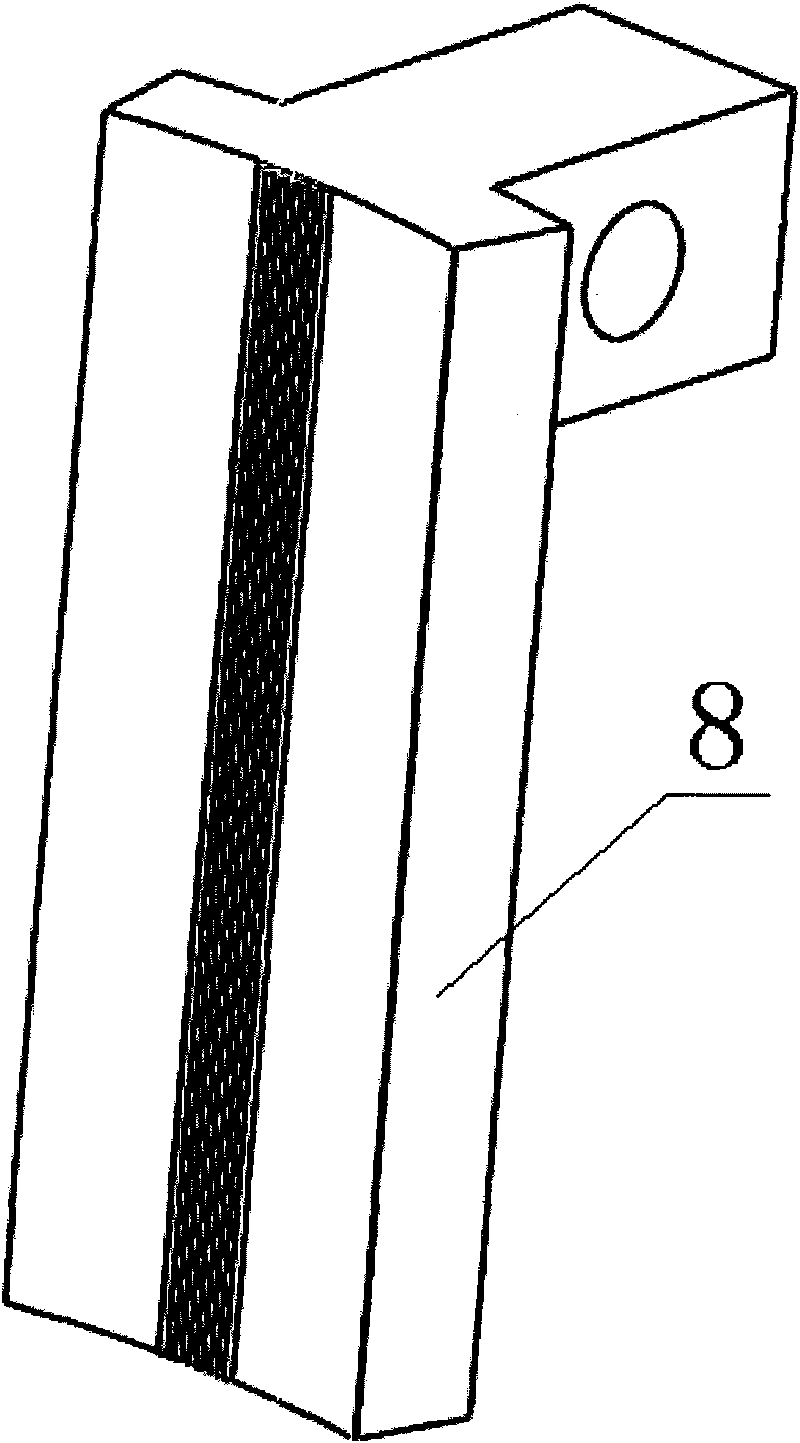

[0024] refer to figure 1 . The torsion-bearing drill pipe elevator device is mainly composed of an upper anti-twist device 1, an upper connecting short 2, a connecting pin 3, a lower connecting short 4, a main clamping block 5, a fixed shaft pin 6, an auxiliary clamping block 7, Lower anti-twist device 8 and safety pin 9 form.

[0025] The upper anti-twist device 1 is a clamping structure with double bolts fixed on the side, that is, the upper anti-twist device 1 is composed of two semi-circular arc-shaped steel plates and two bolts, and the two ends of the semi-circular arc-shaped steel plates are respectively connected with flat steel plates. The thickness of the steel plate is 20mm. The inner walls of the two semicircular steel plates are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com