Liquid helium conveying pipeline and heat sink interface form design

A technology for conveying pipelines and liquid helium, which is applied in the field of interface design between liquid helium conveying pipelines and heat sinks, which can solve problems such as system failure, increased consumption of liquid helium, and increased cold loss of pipelines, and facilitate disassembly and assembly , The consumption of liquid helium is reduced, and the effect of solving low temperature cold leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

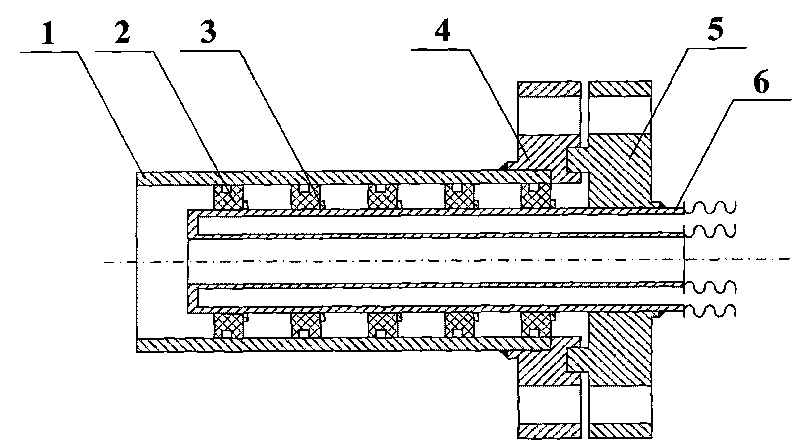

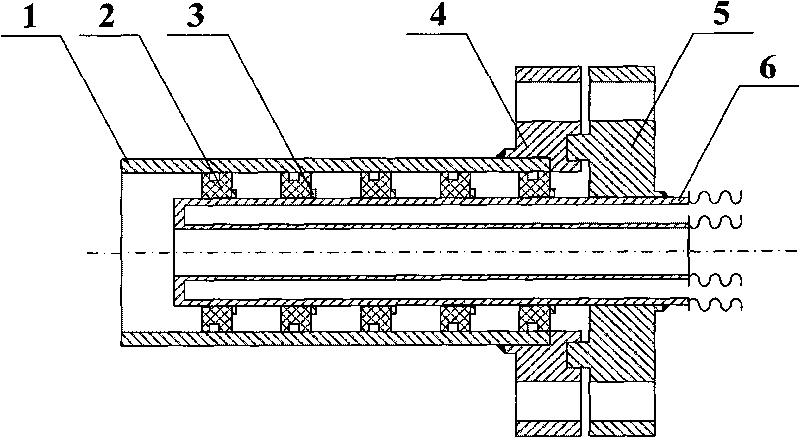

[0011] figure 1 The interface form between the liquid helium delivery pipeline and the heat sink shown is mainly composed of a heat sink pipeline (1), a sealing gasket (2), a positioning ring (3), a container flange (4), a delivery pipeline flange (5), a liquid helium Delivery pipeline (6) is formed.

[0012] Teflon can be used as the sealing gasket material, the number of sealing gaskets is 3 to 10, the connection form of the container flange and the heat sink pipeline is welding, the connection form of the delivery pipeline flange and the liquid helium delivery pipeline is welding, the container flange The flange of the delivery pipeline is connected by bolts, and the liquid helium delivery pipeline adopts a double-layer vacuum Dewar tube with small cold loss.

[0013] The interface between the liquid helium delivery pipe and the heat sink is suitable for both the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com