Laser distance-measuring device and control method thereof

A technology of a distance measuring device and a control method, which is applied in the field of laser distance measuring devices, can solve the problems of inability to calculate to obtain the target object, shrapnel and cam positioning point errors, inability to receive reflected light signals, etc., so as to achieve device volume reduction and manufacturing. The effect of cost reduction and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

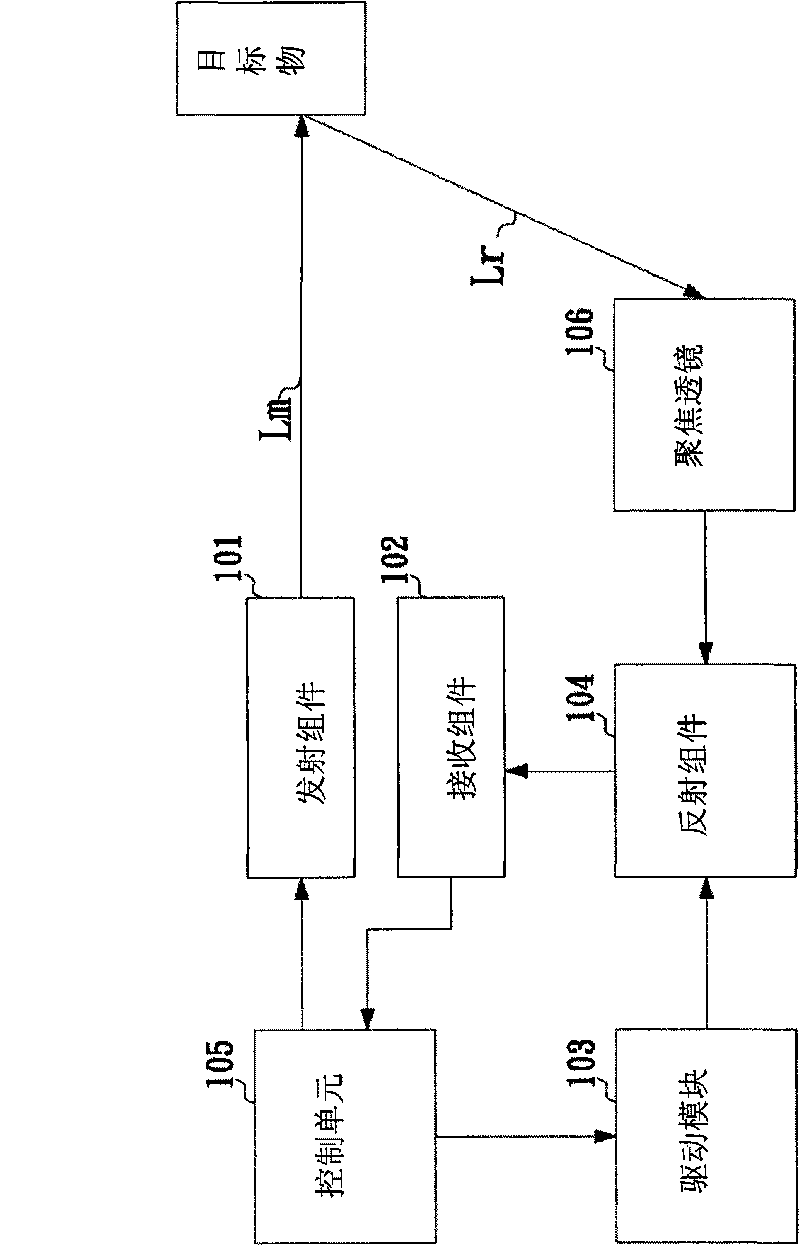

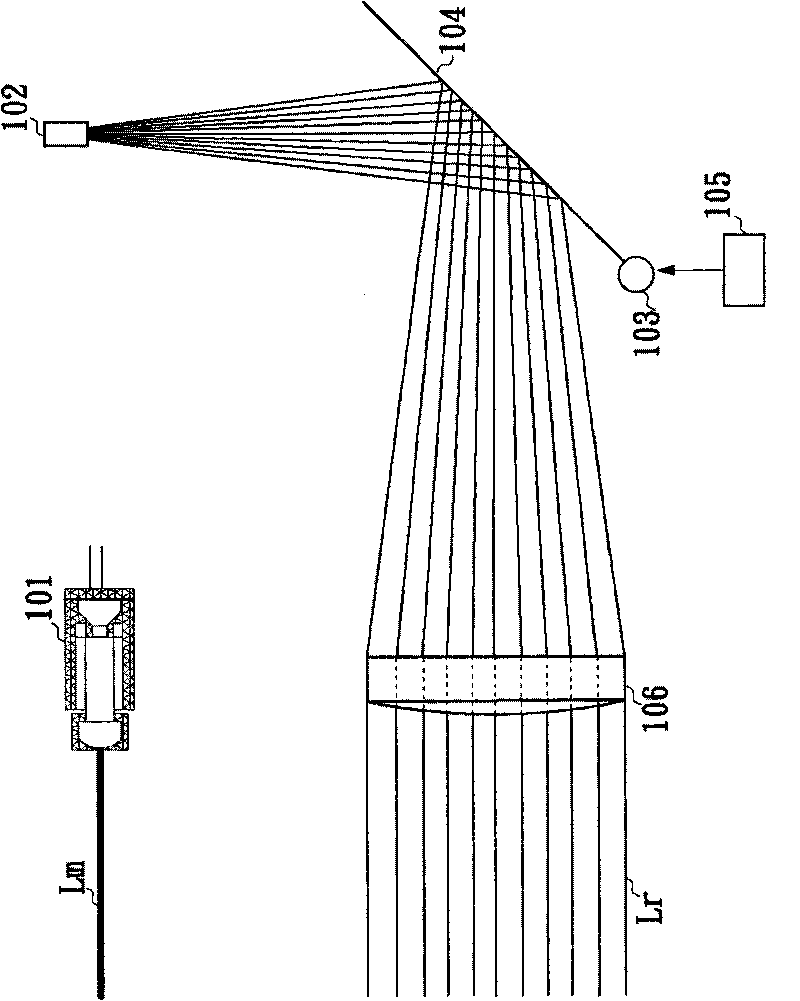

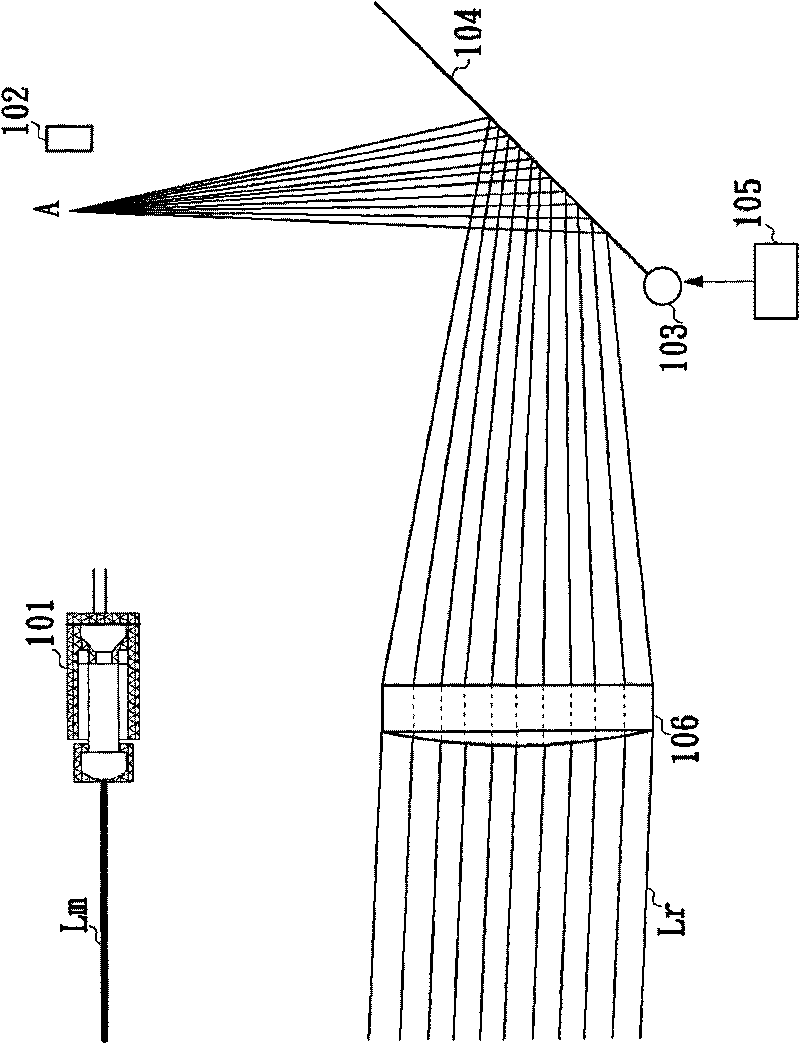

[0014] see figure 1 Shown is the block diagram of the laser ranging device according to the first embodiment of the present invention. The laser ranging device according to the first embodiment of the present invention includes a transmitting component 101 , a focusing lens 106 , a receiving component 102 , a driving module 103 , a reflecting component 104 , and a control unit 105 .

[0015] The emitting component 101 is used for emitting the measurement light Lm to the target object. In this embodiment, the emitting component 101 is a laser module. When the laser distance measuring device intends to measure the distance of the target, the laser module will emit the measurement light Lm to the target. When the measurement light After Lm reaches the target object, it will be reflected back by the target object and become reflected light Lr.

[0016] The focusing lens 106 is used for focusing the reflected light Lr on the receiving component 102 through the reflecting componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com