Pattern correction method and pattern correction device

A pattern and correction fluid technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of larger size, correction fluid being pressed around defective pixels, and uneven thickness of correction fluid, so as to achieve uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

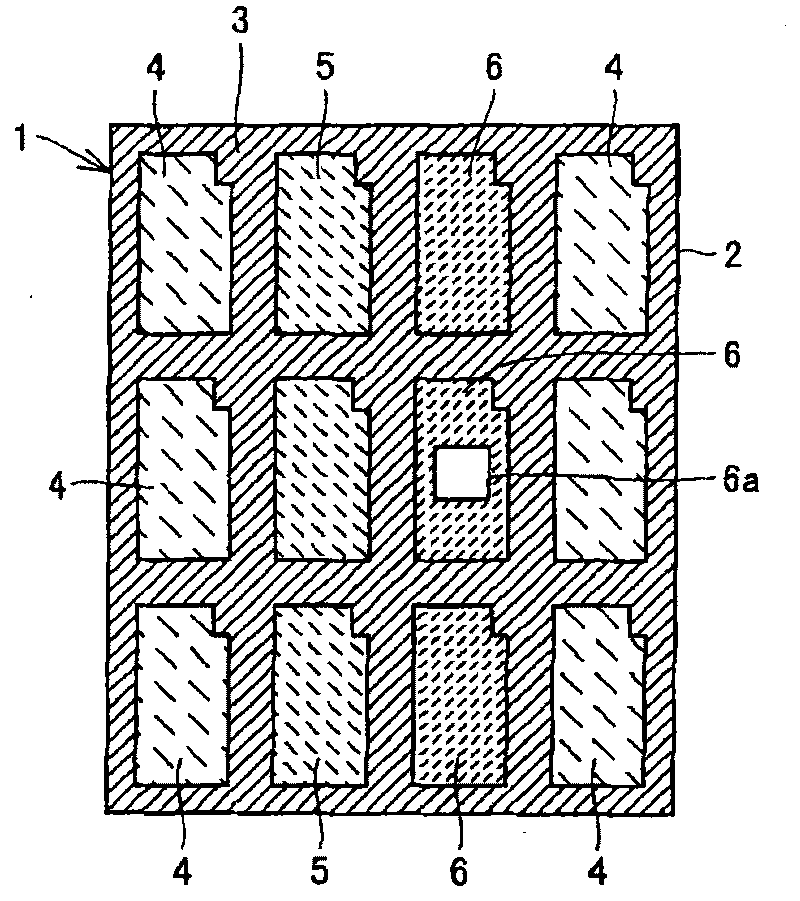

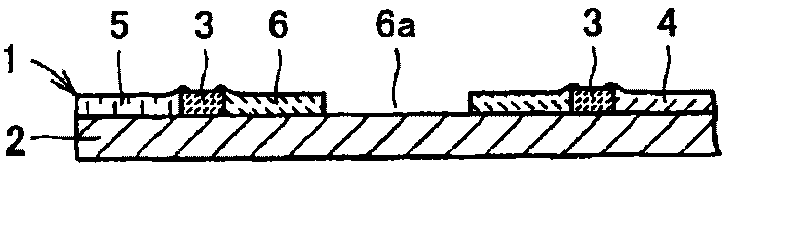

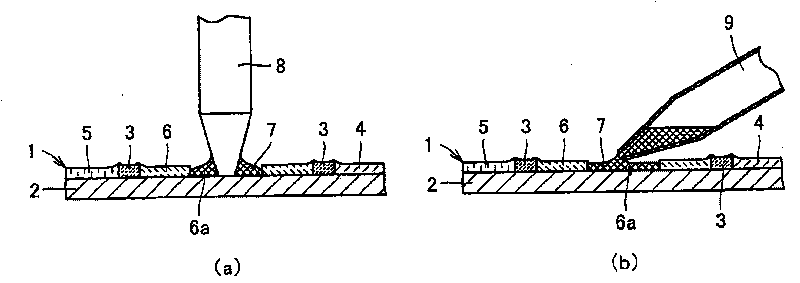

[0079] figure 1 It is a figure which shows the main part of the liquid crystal color filter substrate 1 which is the correction object of the pattern correction method which concerns on one embodiment of this invention, figure 2 is its partial sectional view. figure 1 and figure 2 Among them, the liquid crystal color filter substrate 1 includes a glass substrate 2 . A grid-shaped black matrix 3 is formed on the surface of the glass substrate 2 , and R pixels 4 , G pixels 5 , and B pixels 6 are formed at regular intervals in a plurality of regions surrounded by the black matrix 3 . The R pixel 4 , the G pixel 5 , and the B pixel 6 are composed of red, green, and blue colored layers, respectively. figure 1 and figure 2 A state in which a rectangular white defect 6 a locally exists in the B pixel 6 is shown in . The rectangular white defect 6 a is formed by irradiating a laser beam to a rectangular region including a white defect of an arbitrary shape or a foreign matter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com