Core wire structure for medium-voltage power cable

A power cable and core wire technology, applied in the field of core wire structure of medium-voltage power cables, can solve the problems of complex manufacturing process, shortened operating life of cables, waste of resources, etc., and achieves low cable life cycle cost and simplified water resistance performance structure. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

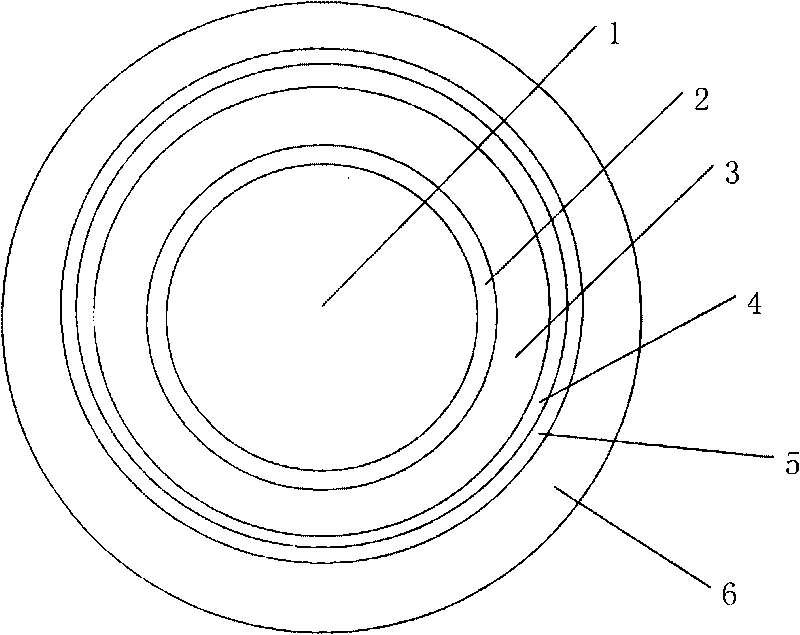

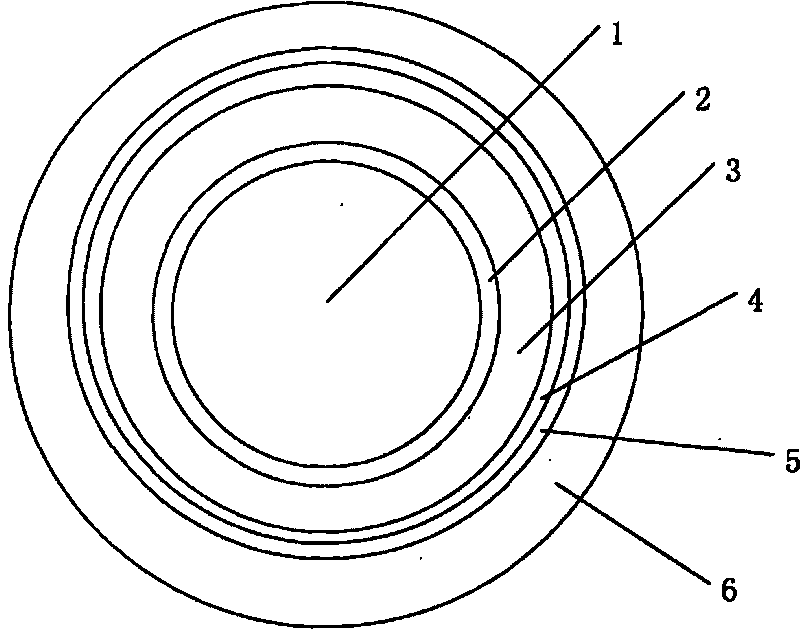

[0011] see figure 1 , the figure shows the core wire structure of the present invention for medium-voltage power cables, which sequentially includes a compact conductor 1, a conductor semi-conductive shielding layer 2, an insulating layer 3, and an insulating semi-conductive shielding layer 4 from the inside to the outside , metal shielding and tape layer 5 and outer sheath 6, and insulating layer 3 is made of high-quality, high-clean insulation material with excellent water tree resistance.

[0012] In the present invention, the compact conductor 1 is a copper conductor, the conductor semiconductive shielding layer 2 adopts semiconductive material with super cleanliness and ultrasmoothness, and the insulating semiconductive shielding layer 4 adopts supercleanliness, supersmoothness, peelable and Semi-conductive material with reliable adhesion, the insulating layer 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com