Connecting part used between high-temperature superconducting segment of heavy current lead and resistance heat exchanger

A technology of high-temperature superconductivity and heat exchangers, which is applied in the fields of connecting contact materials, nuclear power generation, and climate sustainability. It can solve problems such as increased refrigeration costs, achieve small equivalent fluid diameters, improve operational stability and Safety and high heat transfer coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

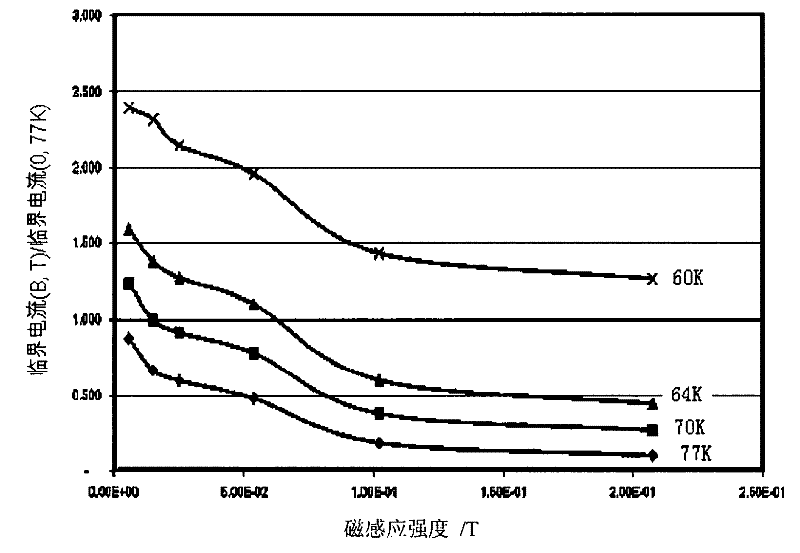

[0018] figure 1 It is the Bi-2223 / Ag-5.3wt.% Au superconducting tape provided by American Superconducting Corporation for HTS current leads. The critical current and the magnetic field component perpendicular to the surface of the tape are at 4 temperatures (77, 70, 64 and 50K) Relationship lines. It can be seen from the figure that the critical current of the silver-gold-based bismuth-based high-temperature superconducting tape is very sensitive to the vertical field under the self-field, and the highest self-field of a pair of extra-large current leads can often reach more than 0.1T. If the HTS operates at 77K temperature, the critical current is lower than 20% under zero field; if the temperature drops to 64K, the critical current can be increased by 3 times; if it is further reduced, the effect is even better.

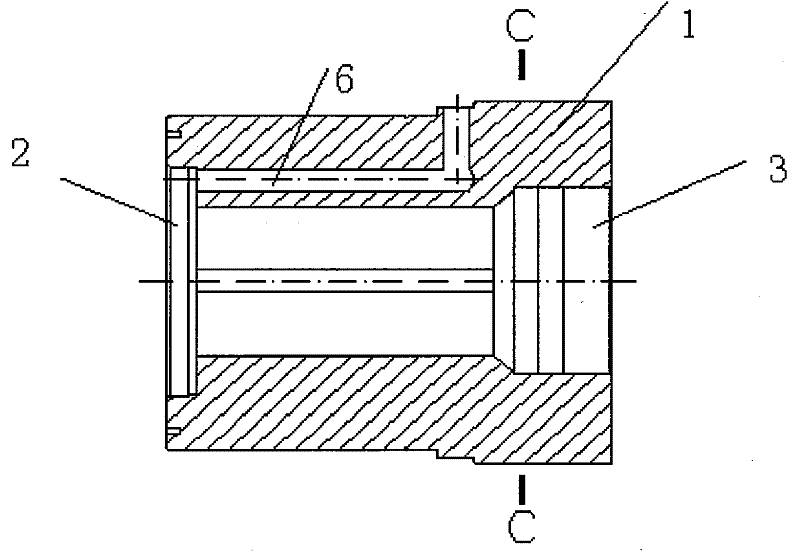

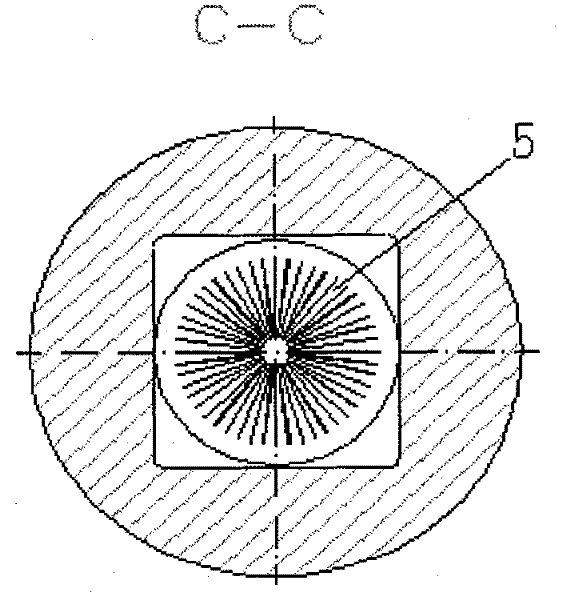

[0019] Figures 2 and 3 are a connector for high heat exchange efficiency between the high-current lead high-temperature superconducting section and the resistive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com