Nitride semiconductor laser diode and manufacturing method thereof

A technology of nitride semiconductors and laser devices, which is applied to semiconductor lasers, the structural details of semiconductor lasers, and the structure of optical waveguide semiconductors. It can solve problems such as insufficient flatness, reduced utilization efficiency, and noise generation, and achieve flatness improvement. , Reliability improvement, and the effect of low working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0041] A first embodiment of the present invention will be described with reference to the drawings. In addition, each of the following embodiments is merely an example, and the present invention is not limited to these embodiments.

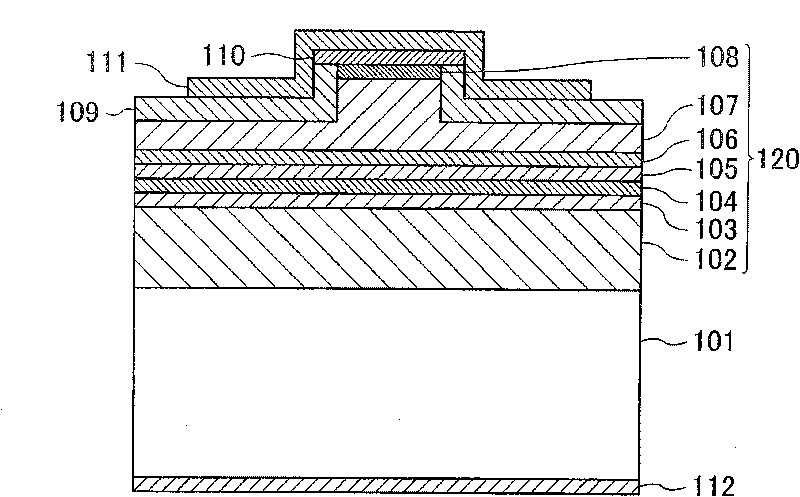

[0042] Such as figure 1 As shown, the nitride semiconductor laser device of the first embodiment has a stacked structure including a plurality of group III nitride semiconductors formed by epitaxial growth on the main surface of a substrate 101 made of, for example, n-type gallium nitride (GaN). 120.

[0043] The laminated structure 120 includes n-type Al x Ga 1-x Nn (where x is 0<x<1) type cladding layer 102, n-type guide layer 103 including n-type GaN; multiple quantum well (MQW) active layer 104 including InGaN, p-type guide layer including p-type GaN layer 105, a p-type carrier block layer 106 including p-type AlGaN, a p-type cladding layer 107 having a superlattice structure including p-type AlGaN and p-type GaN, and a p-type contact lay...

no. 2 approach

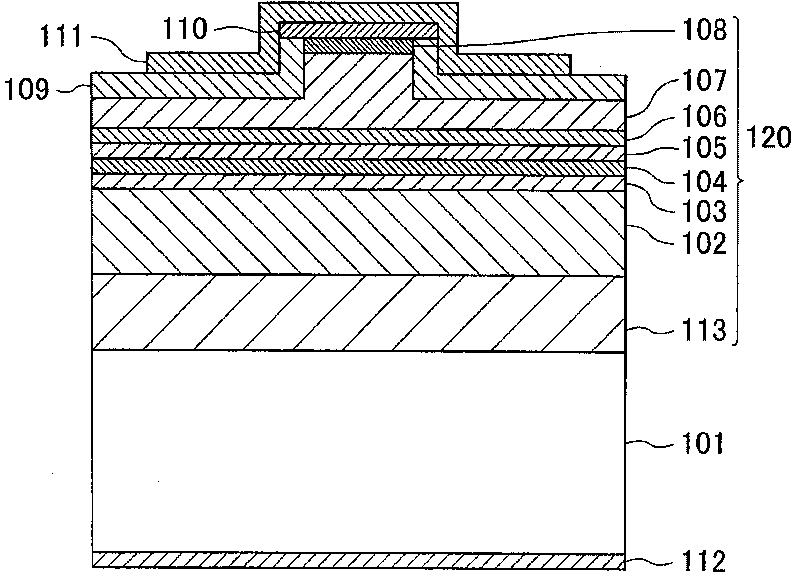

[0082] Below, refer to Figure 5 At the same time, a nitride semiconductor laser device according to a second embodiment of the present invention will be described. Here, its structure will be described together with the method of manufacturing the nitride semiconductor laser device according to the second embodiment.

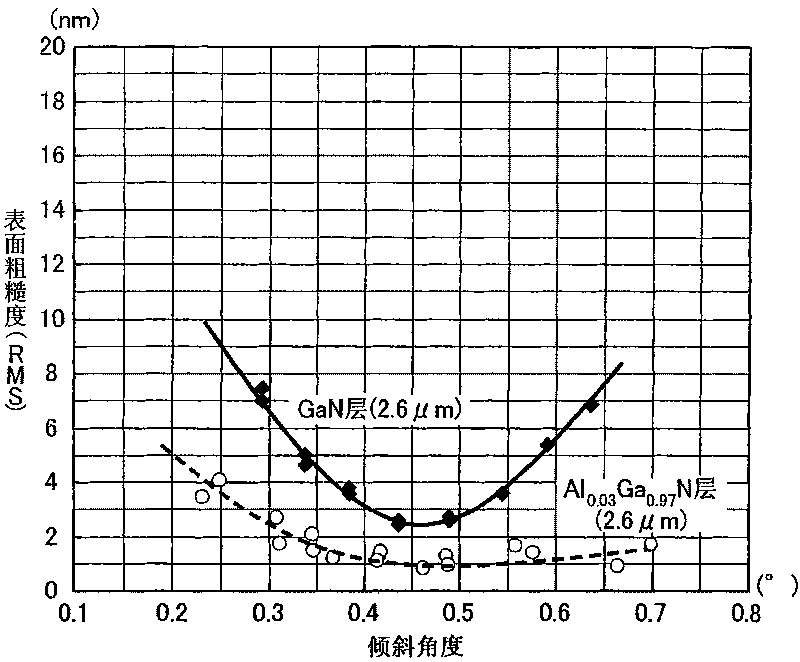

[0083] First, if Figure 5 As shown, the prepared main surface is inclined about 0.4° relative to the (0001) plane axis of the plane orientation, and the average impurity concentration including the donor is 1×10 18 cm -3 The left and right n-type GaN substrates 114 . In the substrate 114 prepared in the second embodiment, layers having a high donor impurity concentration and layers having a low donor impurity concentration are alternately stacked in the thickness direction of the substrate 114 , that is, the impurity concentration of the donor varies periodically. Here, silicon (Si) can be used as the donor impurity.

[0084] Next, the substrate 114 is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com