Process for obtaining steroidal phosphate compounds

A technology of compounds and phosphate esters, used in pharmaceutical formulations, drug combinations, medical preparations containing active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

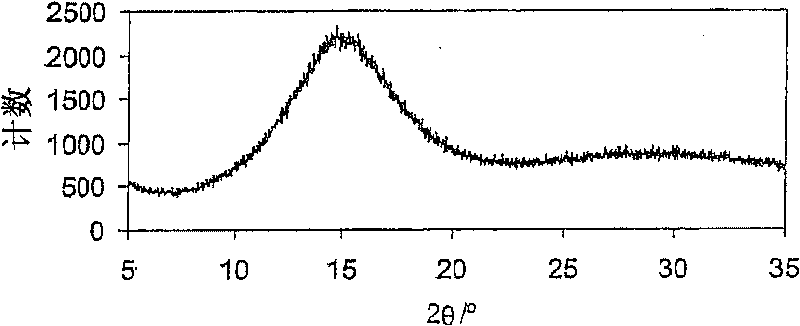

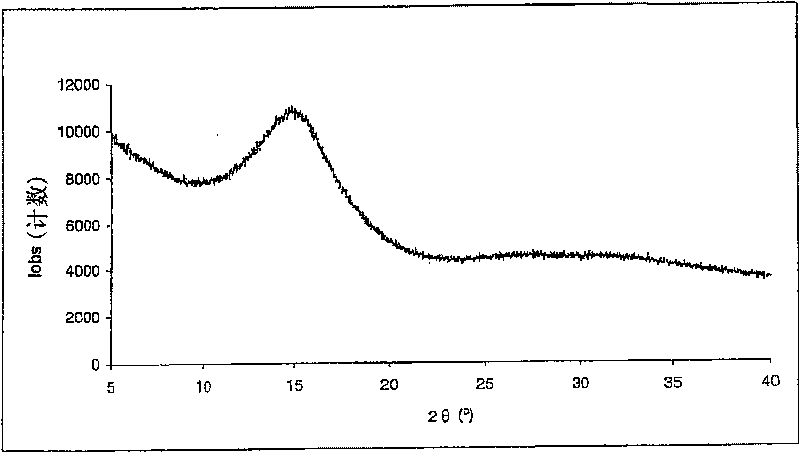

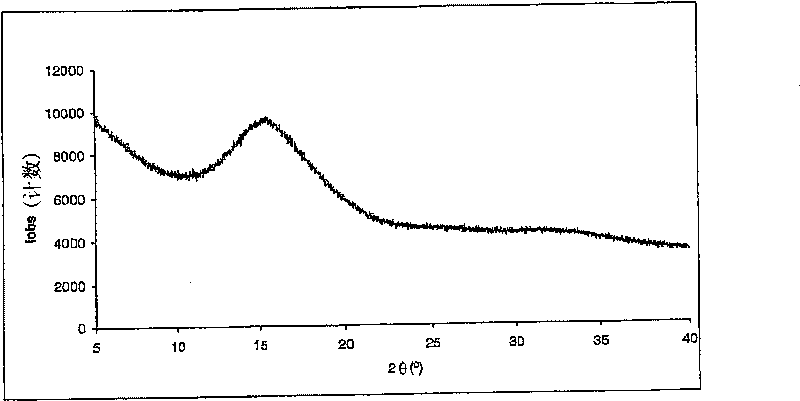

Image

Examples

Embodiment 1

[0067] Embodiment 1: the spray drying of betamethasone 21-phosphate disodium

[0068] Wet betamethasone 21-phosphate disodium having a purity of 99.8% (HPLC area %) obtained by applying literature techniques was dissolved in water to obtain a 5% by weight solution on dry matter basis. The pH of the solution was adjusted to 7.6 / 7.9 by adding 1N hydrochloric acid. The outlet temperature was maintained between 80°C and 100°C, the atomization flow rate was 357-670 standard liters per hour, and the solution flow rate was between 5ml / min and 9ml / min. The product was collected in a high performance cyclone. The product [betamethasone 21-phosphate] was obtained with a purity of 99.6% and residual solvents meeting the requirements of the USP and EP pharmacopoeias (methanol: 428 ppm; isopropanol: 2088 ppm; water, by Karl-Fischer method: 8.0% by weight).

Embodiment 2

[0069] Embodiment 2: the spray drying of dexamethasone 21-phosphate disodium

[0070] Dexamethasone disodium 21-phosphate having a purity of 99.2% (HPLC area %) was dissolved in water to obtain a 5% by weight solution. The pH of the solution was adjusted to 7.6 / 7.9 by adding 1N hydrochloric acid. The outlet temperature was maintained between 80°C and 100°C, the atomization flow rate was 357-670 standard liters per hour, and the solution flow rate was between 5ml / min and 9ml / min. The product was collected in a high performance cyclone. The product [dexamethasone 21-phosphate] was obtained with a purity of 99.2% (HPLC area %).

Embodiment 3

[0071] Embodiment 3: the spray drying of prednisolone 21-phosphate disodium

[0072] Disodium prednisolone 21-phosphate with a purity of 98.4% (HPLC area %) was dissolved in water to obtain a 5% by weight solution. The pH of the solution was adjusted to 7.6 / 7.9 by adding 1N hydrochloric acid. The outlet temperature was maintained between 80°C and 100°C, the atomization flow rate was 357-670 standard liters per hour, and the solution flow rate was between 5ml / min and 9ml / min. The product was collected in a high performance cyclone. The product [prednisolone 21-phosphate] was obtained with a purity of 99.2% (HPLC area %).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com