Grain cleaning loss detection method for combined harvester and device thereof

A combine harvester and detection device technology, applied in the direction of harvesters, measuring devices, cutters, etc., can solve the problems of reduced operation quality, incomplete grain information, difficulty in identifying and extracting grain signals, and achieve enhanced grain Shock signal, improve the recognition accuracy of grain and grass, and improve the effect of test reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

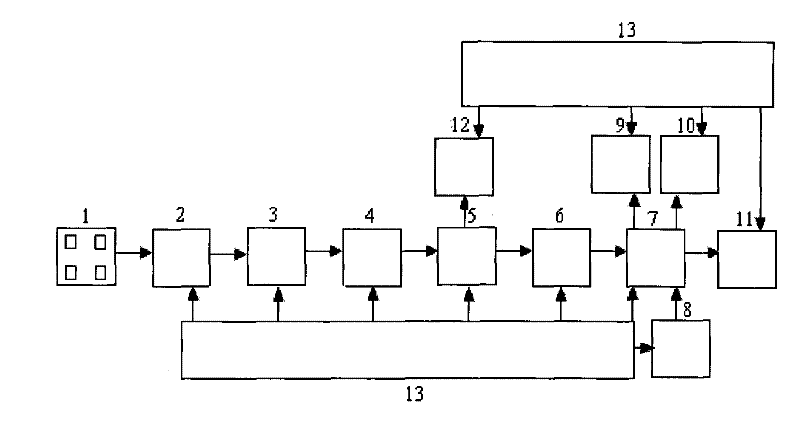

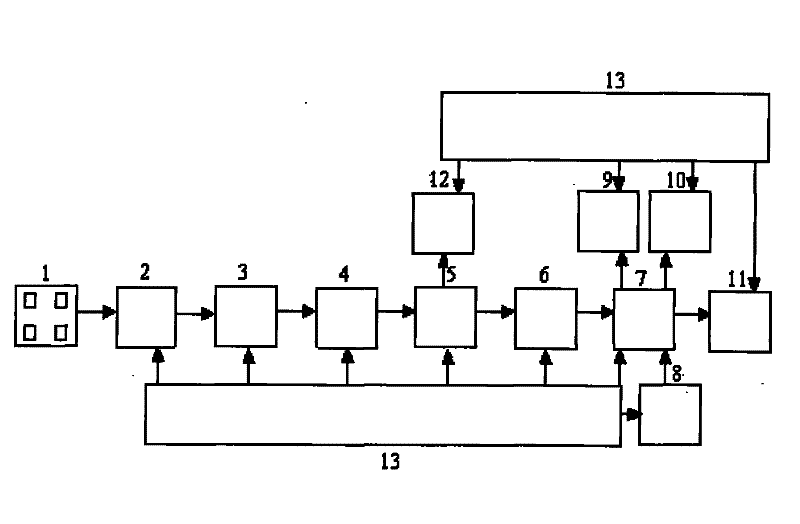

[0016] like figure 1 In the detection device shown, the output of the array piezoelectric crystal sensor 1 is connected to the charge amplifier 2, and the output of the charge amplifier 2 is sequentially connected in series with the gain adjustable circuit 3, the high-pass filter circuit 4, the sensitivity adjustment circuit 5, the pulse shaping circuit 6, the single On-chip microprocessor 7 and communication interface circuit 11. Wherein, the output of the sensitivity adjustment circuit 5 is bypassed to the sensitivity voltage display digital tube 12 , and the output of the single-chip microprocessor 7 is also connected to the alarm circuit 9 and the main display digital tube 10 . The output of the keyboard 8 is connected to the single-chip microprocessor 7 . Power supply circuit 13 connects above-mentioned each circuit respectively and provides power supply for each circuit, and power supply circuit 13 also connects charge amplifier 2, single-chip microprocessor 7, keyboard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com