Ecological treatment oil cream rinse and preparing method thereof

A technology of hair dye cream and baking oil, which is applied in the field of daily chemicals, can solve the problems of human injury and poor hair dyeing effect, and achieve the effect of soft and smooth hair, good luster and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

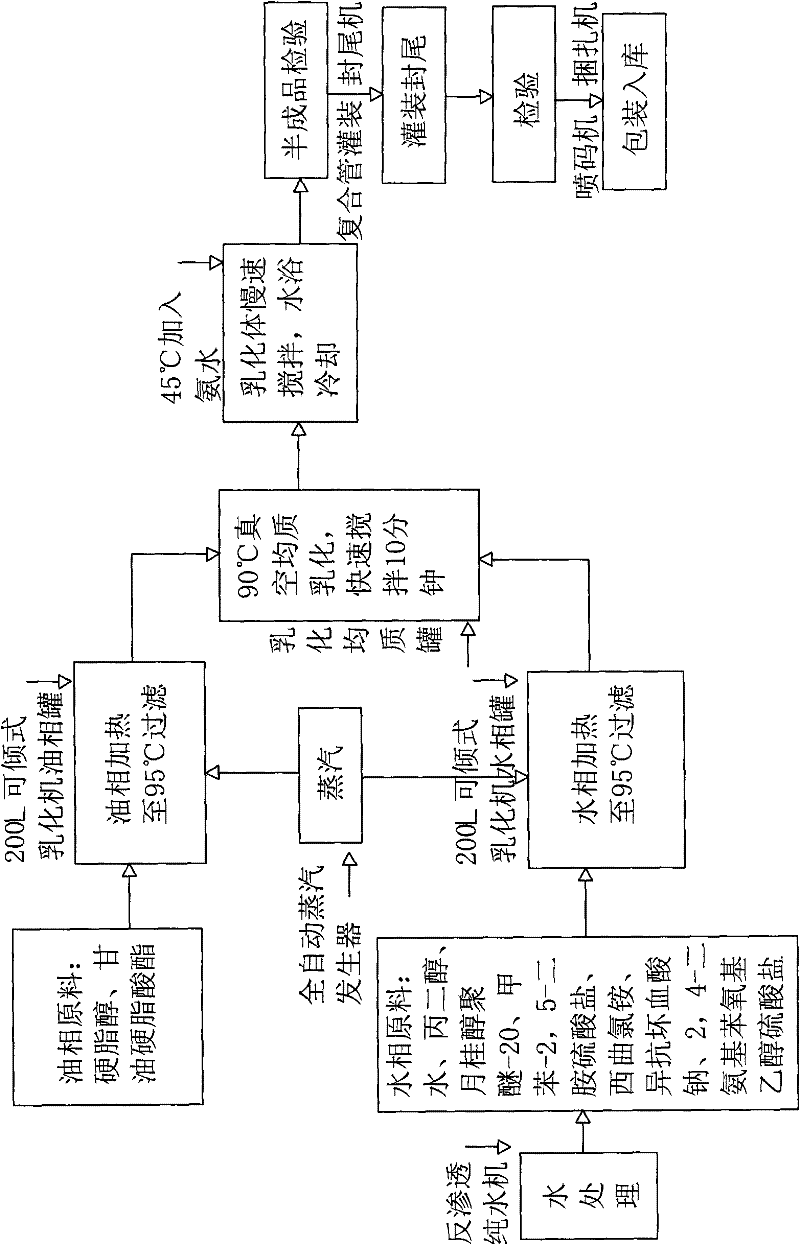

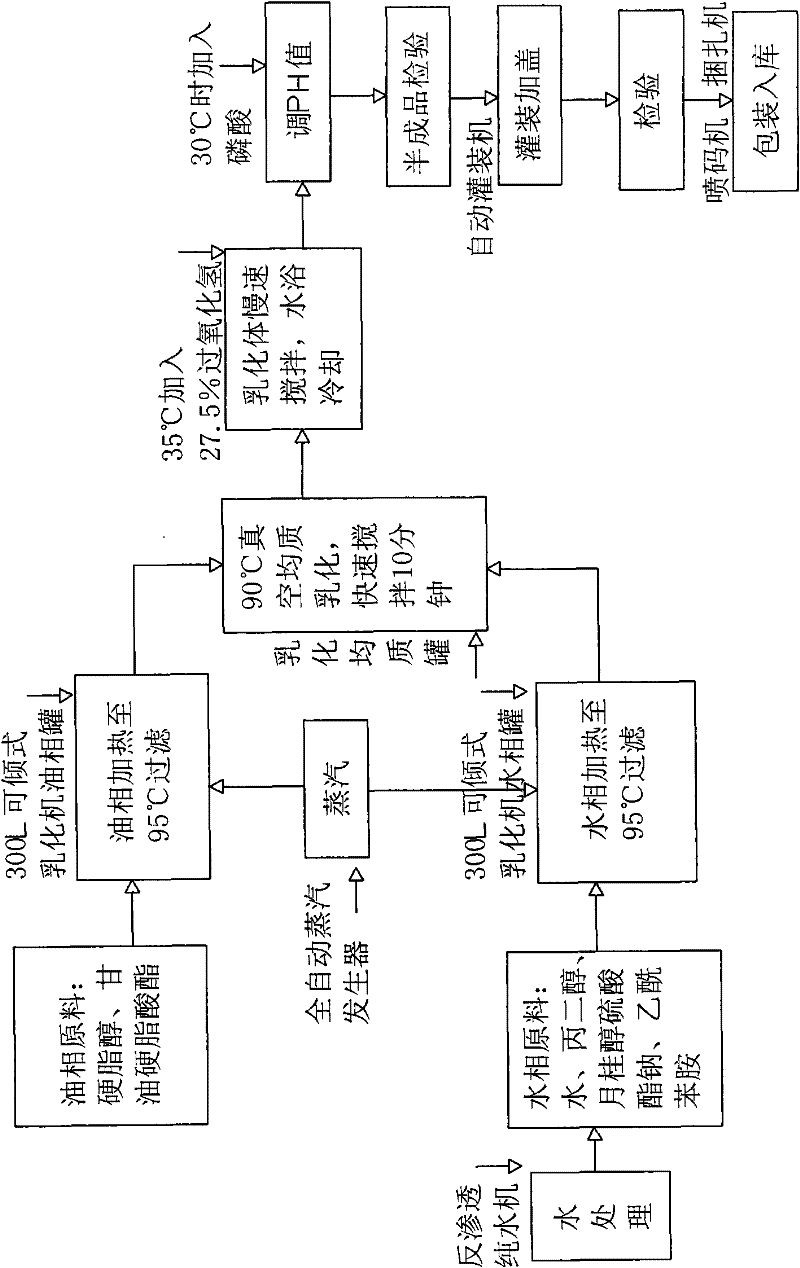

Method used

Image

Examples

Embodiment 1

[0023] The eco-baked oil hair dyeing cream of the present invention is a combination agent, comprising a hair dye and an oxidant;

[0024] The weight percent of each component in the hair dye is: 8% of stearyl alcohol, 4% of glyceryl stearate, 4% of propylene glycol, 3% of ammonia water, namely ammonium hydroxide, and the weight percent of NH in the ammonia water The concentration is 20%, the leveling agent laureth-20 is 3%, the dye intermediate toluene-2,5-diamine sulfate is 1%, and the dye intermediate 2,4-diaminophenoxyethanol sulfate is 0.1%, emulsifier cetrimonium chloride is 0.9%, antioxidant sodium erythorbate is 0.3%, solvent deionized water is 75.7%;

[0025] The weight percentage of each component in the oxidizing agent is: stearyl alcohol is 6%, glyceryl stearate is 5%, hydrogen peroxide is 5%, the weight percentage concentration of the hydrogen peroxide is 27.5%, and propylene glycol is 3% , the emulsifier sodium lauryl sulfate is 1%, the stabilizer acetanilide is...

Embodiment 2

[0037] The eco-baked oil hair dyeing cream of the present invention is a combination agent, comprising a hair dye and an oxidant;

[0038] The weight percentage of each component in the hair dye is: 9% of stearyl alcohol, 3% of glyceryl stearate, 5% of propylene glycol, 3% of ammonia water, namely ammonium hydroxide, and the weight percentage of NH in the ammonia water The concentration is 20%, the leveling agent laureth-20 is 4%, the dye intermediate toluene-2,5-diamine sulfate is 2%, and the dye intermediate 2,4-diaminophenoxyethanol sulfate is 0.08%, emulsifier cetrimonium chloride is 0.8%, antioxidant sodium erythorbate is 0.3%, solvent deionized water is 74.82%;

[0039] The weight percent of each component in the oxidizing agent is: 7% of stearyl alcohol, 4% of glyceryl stearate, 5% of hydrogen peroxide, 27.5% of the weight percent concentration of this hydrogen peroxide, and 4% of propylene glycol , the emulsifier sodium lauryl sulfate is 1%, the stabilizer acetanilide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com