Original potential control flotation technology for copper ore with unmanageable high-magnetic pyrite content

A potential control, pyrite technology, applied in flotation, solid separation and other directions, can solve the problems of harsh natural conditions, serious environmental pollution, difficult and efficient recycling of non-ferrous metal mineral resources, etc., to achieve efficient separation and improve separation indicators , improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

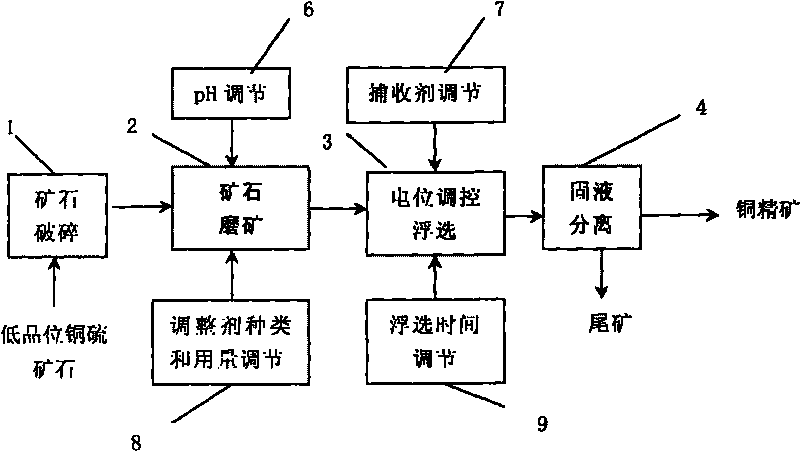

[0023] Such as figure 1 As shown, 1 is the refractory low-grade copper sulfide ore crushing process; the crushed ore is sent to the ore grinding process 2; the pulp concentration in the ore grinding process is 66%, and during the ore grinding process, lime is added through process 6 to adjust the pH Adjustment and process 8 carry out adjustment agent type and dosage control, after the grinding process is adjusted, carry out potential control flotation process 3, the pulp concentration in the flotation process is 33%, during the ore flotation process, add collectors through process 7, process 9. Adjust the flotation time to control the pulp potential in the flotation process. The pulp in process 3 enters the solid-liquid separation treatment process 4. After the process 4 is processed, copper concentrate and tailings are obtained.

[0024] The present invention will be further described below in conjunction with embodiment:

[0025] The copper grade in Saishitang copper sulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com