Novel gelled material and product

A technology for cementitious materials and products, applied in the field of building materials, can solve the problems of reduced joint strength of secondary pouring concrete, fire prevention, waterproof and anti-seepage, poor anti-freezing performance, and performance that cannot meet engineering requirements, so as to reduce greenhouse gas emissions. , Environmentally significant, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

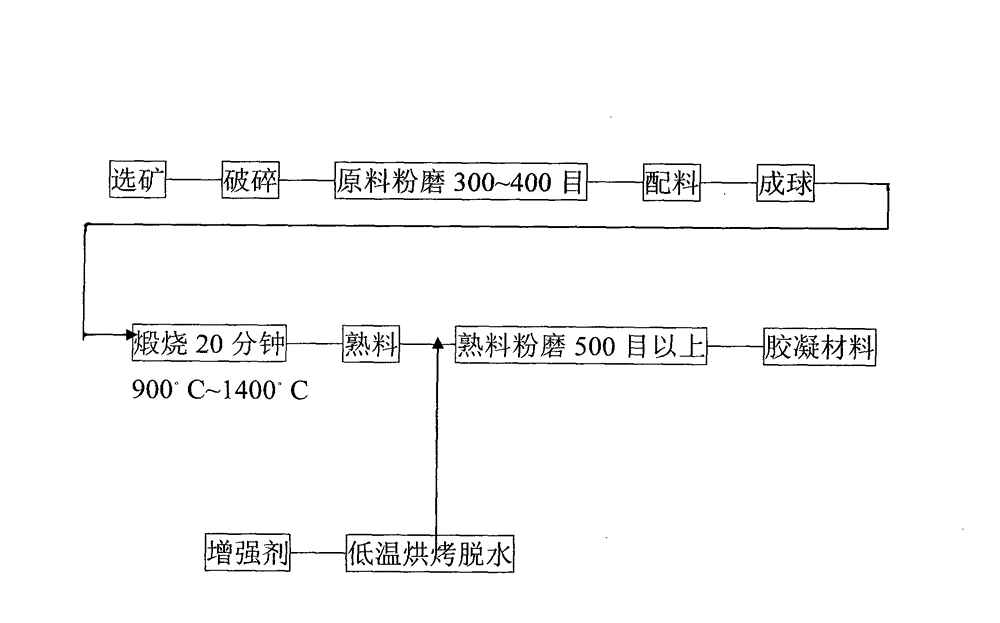

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] 1. Examples of cementitious materials:

[0019] A cementitious material, the ratio of raw materials is as follows: basalt 75-85, dolomite 0-10, porcelain stone 5-15, zeolite 5-10.

[0020] The basalt is replaced by serpentinite or garnet, and processed through ore dressing. 3-5% reinforcing agent of the total amount can also be added in addition by weight ratio, and the reinforcing agent is phosphate, with apatite Ca 5 [PO 4 ][F, Cl] low temperature baking dehydration treatment.

[0021] The chemical composition ratio contained in the raw material is by weight: MgO 17.5-21.9, Al 2 o 3 6.7-8.4, SiO 2 40.3-46.1, Fe 2 o 3 13.1-15, CaO 5.8-8.8, loss on ignition 5.2-10 other balance K 2 O, Na 2 O, TiO 2 1.2-1.6.

[0022] Several gelling materials of the present invention are exemplified as follows:

[0023] 1. For ordinary wall cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com