Warm mixing and antiflaming asphalt mixture and preparation method thereof

A technology of asphalt mixture and warm mixing, which is applied in the field of preparation of warm-mix flame-retardant asphalt mixture and warm-mix flame-retardant asphalt mixture. Less equipment corrosion and high concentration of flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A, prepare each component according to asphalt: organic viscosity reducer EC-120: high-efficiency composite flame retardant: crushed stone: inert filler = 4.7: 0.14: 1.36: 91.0: 2.8;

[0038] B. Put the inert filler and gravel heated to 140°C into the mixing tank for dry mixing for not less than 5 seconds, then add the hot asphalt heated to 145°C into the mixing tank, then add the organic viscosity reducer and Add the high-efficiency composite flame retardant into the mixing tank and stir for 40 seconds, so that the organic viscosity reducer and high-efficiency composite flame retardant are evenly coated on the gravel until the gravel is covered with asphalt and no white material;

[0039] C. Unloading: Control the exit temperature of the mixture at 135°C to obtain the warm-mix flame-retardant asphalt mixture.

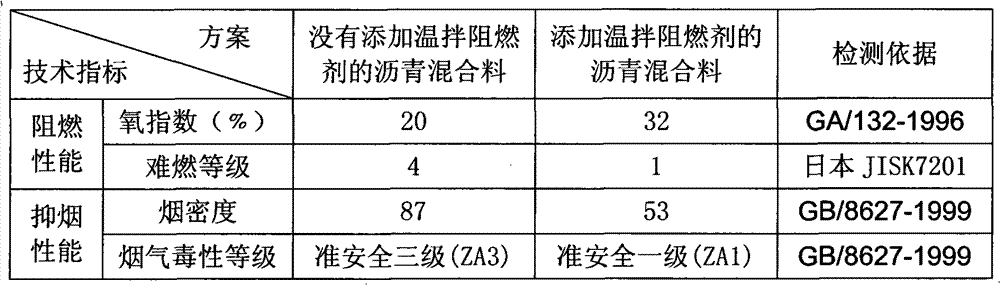

[0040] The test method of this embodiment is implemented in accordance with the industry standard JTJ052-2000 "Test Regulations for Asphalt and Asphalt Mixtures...

Embodiment 2

[0046] A, according to asphalt: organic viscosity reducer EC-120: high-efficiency composite flame retardant: gravel: inert filler = 4.7: 0.05: 1.45: 91.0: 2.8, prepare each component;

[0047] B. Put the inert filler and gravel heated to 145°C into the mixing tank for dry mixing for not less than 5 seconds, then add the hot asphalt heated to 145°C into the mixing tank, and then add the organic viscosity reducer and Add the high-efficiency composite flame retardant into the mixing tank and stir for 45 seconds, so that the organic viscosity reducer and high-efficiency composite flame retardant are evenly coated on the gravel until the gravel is covered with asphalt and no white material;

[0048] C. Unloading: Control the exit temperature of the mixture at 140°C to obtain the warm-mix flame-retardant asphalt mixture.

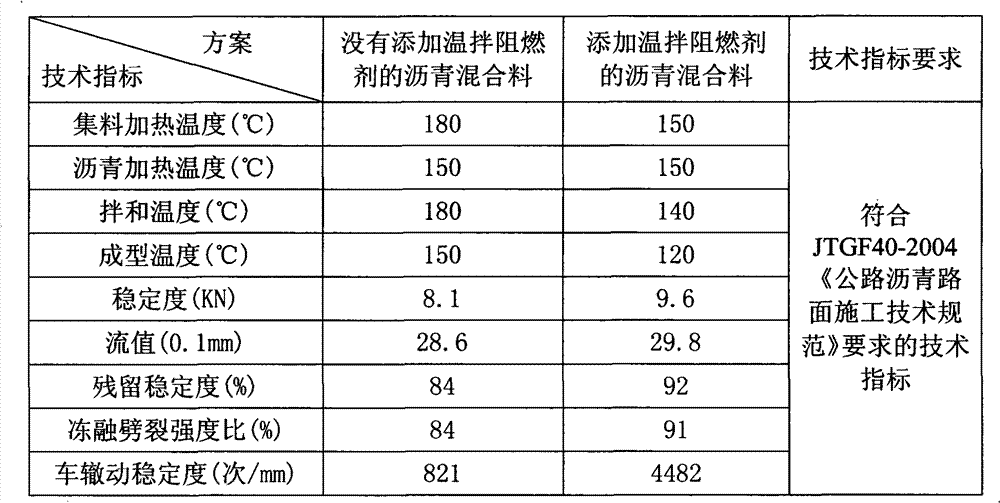

[0049] Test methods and technical standards are implemented with reference to Example 1. The following is a comparison between the asphalt mixture with warm mix fl...

Embodiment 3

[0055] A. According to asphalt: warm mix agent EC-120: high-efficiency composite flame retardant: crushed stone: inert filler = 4.7: 0.09: 1.41: 91.0: 2.8, prepare each component;

[0056] B. Put the inert filler and gravel heated to 150°C into the mixing tank for dry mixing for not less than 5 seconds, then add the hot asphalt heated to 145°C into the mixing tank, then add the organic viscosity reducer and Add the high-efficiency composite flame retardant into the mixing tank and stir for 50 seconds, so that the organic viscosity reducer and high-efficiency composite flame retardant are evenly coated on the gravel until the gravel is covered with asphalt and no white material;

[0057] C. Unloading: Control the exit temperature of the mixture at 140°C to obtain the warm-mix flame-retardant asphalt mixture.

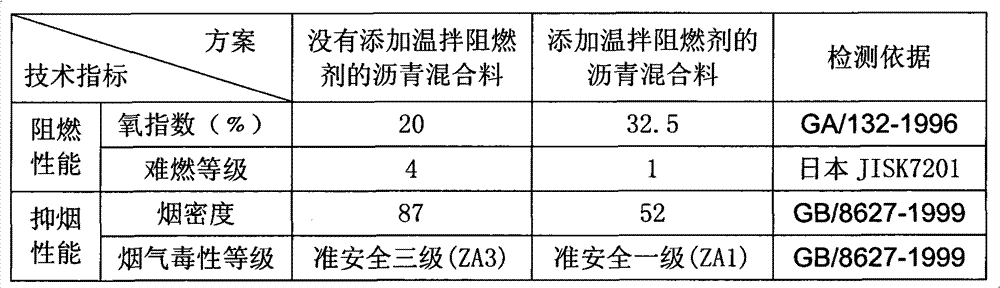

[0058] Test methods and technical standards are implemented with reference to Example 1. The following is a comparison of the asphalt mixture with warm mix flame retarda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com