Method for extracting iodine-containing amino acid from fresh kelp

An amino acid and kelp technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as few studies, and achieve the effect of simple extraction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

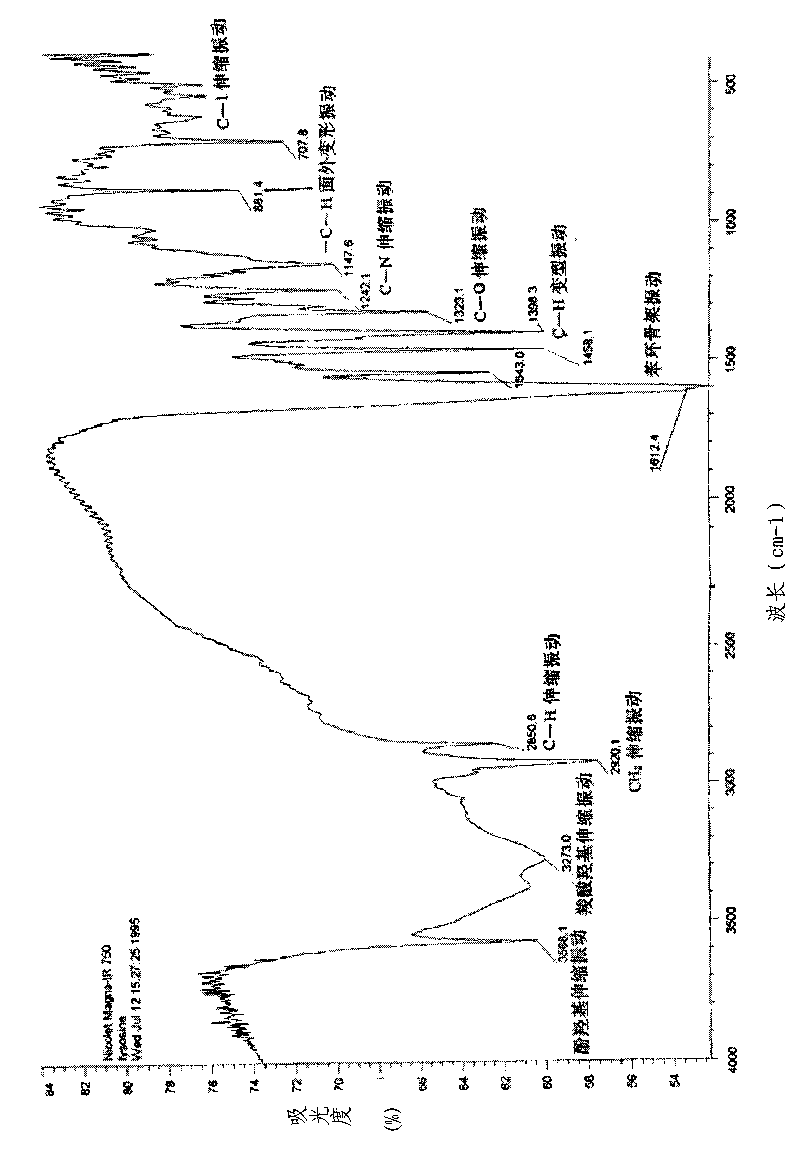

Method used

Image

Examples

Embodiment 1

[0026] Take 100 kg of artificially cultured kelp, wash it with water to remove impurities and foreign matter. Use a shredder to cut the dry kelp that does not contain moisture on the surface into 1-2cm fritters, transfer it to 1000 kilograms of interlayer conical reactors, add mass concentration 15% formic acid (HCOOH, adopt mass concentration 85% formic acid stock solution Allotment) 300 kilograms, and the reactor automatically stirred and extracted for 16 hours. The filtrate is filtered with a plate filter, and the collected filtrate is concentrated to 20 kg with a steam three-effect concentration tank. Adjust the pH to 2.0, and concentrate on a 732 cation exchange resin column (30×150cm), and use 20 kilograms of 1mol / L NH 4 OH was eluted, and continued to concentrate to dryness with a steam three-effect concentration tank, and the obtained product contained 340 grams of iodine-containing amino acid crude product.

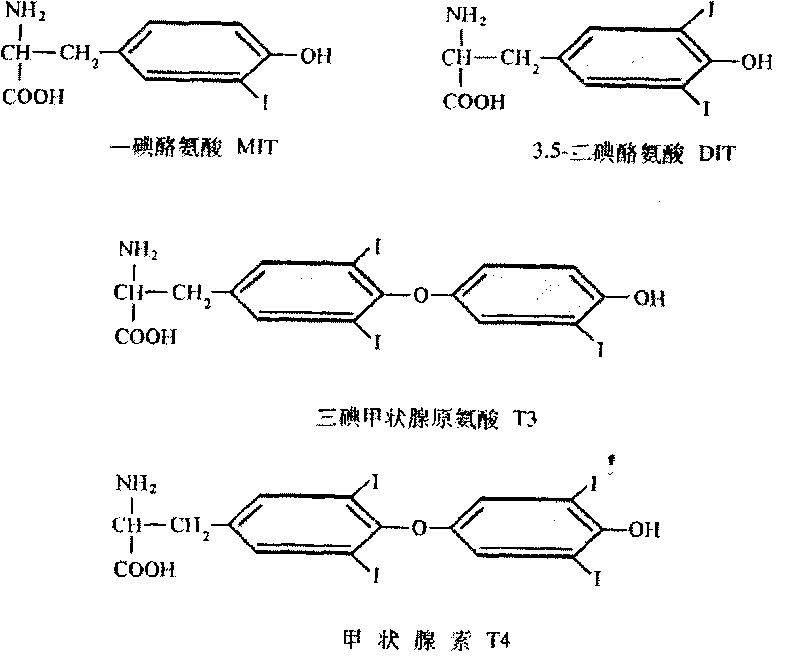

[0027] The chemical structure of iodine-containing amino ...

Embodiment 2

[0030] Take 100 kg of artificially cultured kelp, wash it with water to remove impurities and foreign matter. Use a shredder to cut the dry sea-tangle that does not contain moisture on the surface into 1-2cm fritters, transfer it to 1000 kilograms of interlayer conical reactors, add mass concentration 18% formic acid (HCOOH, adopt mass concentration 85% formic acid stock solution Allotment) 400 kilograms, and the reactor automatically stirred and extracted for 20 hours. The filtrate is filtered with a plate filter, and the collected filtrate is concentrated to 30 kg with a steam three-effect concentration tank. Adjust the pH to 3.0, and concentrate on a 732 cation exchange resin column (30×150cm), and use 30 kilograms of 1.5mol / L NH 4 OH was eluted, and continued to concentrate to dryness with a steam three-effect concentration tank, and the obtained product contained 370 grams of iodine-containing amino acid crude product.

Embodiment 3

[0032] Take 100 kg of artificially cultured kelp, wash it with water to remove impurities and foreign matter. Put the clean kelp in a hanging cage of 1m in length x width x height to control the water for 1 hour, cut the water-controlled kelp into small pieces of 3-5cm with a shredder, put it into a tissue grinder and homogenize it for 2 minutes. Collect the kelp homogeneous solution, add 350 kg of 6mol / L HCl solution in a stainless steel stirring pot, stir and extract continuously at room temperature for 20 hours, filter on a plate, and concentrate the filtrate to 17 kg with a three-effect concentration evaporator, and adjust the pH to 2.5; 732 cation exchange resin column (30×150cm) was concentrated, eluted with 17 kg of 0.05mol / L NaOH, and concentrated to dryness with a concentration evaporator to obtain 600 grams of iodine-containing amino acid crude product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com