Method for preparing glycal

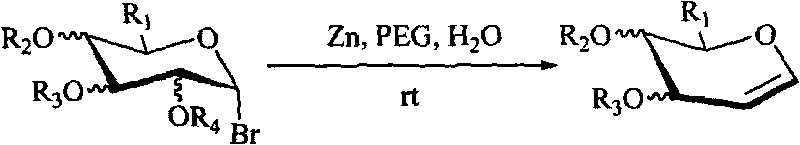

A technology of vinyl sugar and benzoylated vinyl sugar, which is applied in the direction of organic chemistry, can solve the problems of cumbersome operation, high cost, and low yield, and achieve the effect of short process flow, low cost and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

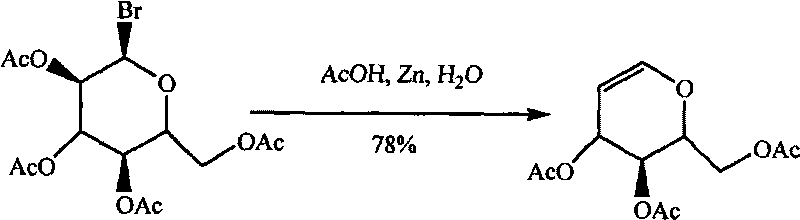

example 1

[0018] Example 1: Add 100mg of acetylated glucosinolate bromide, 0.5mL PEG-600 and 0.5mL H2O to a 25mL round bottom flask, add 32mg of zinc powder, stir and react at room temperature for 20 minutes, after TLC detects that the reaction is complete, purify by silica gel column , to obtain 58 mg of pure acetylated glucal sugar, with a yield of 88%.

example 2

[0019] Example 2: Add 100mg acetylated glucosinolate bromide, 0.5mL PEG-400 and 0.5mL H2O to a 25mL round bottom flask, add 32mg zinc powder, stir and react at room temperature for 20 minutes, after the reaction is complete by TLC, purify by silica gel column , to obtain 55 mg of pure acetylated glucal, with a yield of 83%.

example 3

[0020] Example 3: Add 100mg of acetylated glucosinolate bromide, 0.5mL PEG-2000 and 0.5mL H2O to a 25mL round bottom flask, add 32mg of zinc powder, stir and react at room temperature for 20 minutes, after TLC detects that the reaction is complete, purify by silica gel column , to obtain 57 mg of pure acetylated glucal sugar, with a yield of 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com